Buffer displacement mechanism of laser cutting machine

A laser cutting machine and buffer displacement technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting cutting progress, cutting head vibration, and long Y-axis moving track, so as to achieve strong practicability and improve Air Quality Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

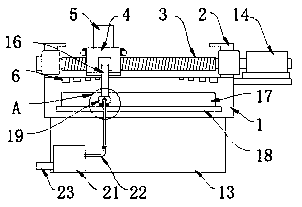

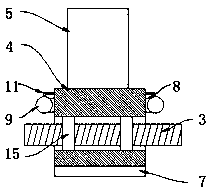

[0028] refer to figure 1 , image 3 and Figure 4 , a buffer displacement mechanism of a laser cutting machine, comprising a cutting machine table 1, the bottom of the cutting machine table 1 is provided with a frame plate 13, and the right side of the cutting machine table 1 is provided with a servo motor 14 coupled with a laser cutting machine numerical control box , the two ends of the upper surface of the cutting machine table 1 are provided with limit blocks 2, and the same drive screw 3 is connected between the two limit blocks 2 through bearing rotation, and the surface of the drive screw 3 is provided with a lateral shock-absorbing displacement Block 4, the upper surface of the transverse damping displacement block 4 is provided with an X-axis cutting frame 5, and a screw nut 15 is arranged between the transverse damping displacement block 4 and the driving screw mandrel 3, and the screw nut 15 and the transverse damping displacement block 4 fixed connection.

[002...

Embodiment 2

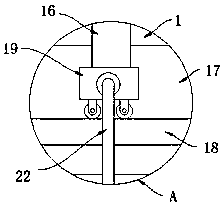

[0034] refer to figure 1 , figure 2 and Figure 5 , different from Embodiment 1, the front side of the transverse damping displacement block 4 is fixedly connected with the connecting rod 16 located at the front side of the cutting machine table 1, and the front side of the cutting machine table 1 has a movable hole 17, and the front side of the cutting machine table 1 is located at the The bottom of the movable hole 17 is provided with a movable flat plate 18, and the bottom of the connecting rod 16 is fixedly connected with a dust-absorbing stick box 19 which passes through the movable hole 17 and is positioned at the X-axis cutting frame 5 below. The bottom of the dust-absorbing stick box 19 is provided with a The rolling wheel on the movable flat plate 18 top, the upper surface of the dust-absorbing bar box 19 offers a plurality of dust-absorbing holes 20 .

[0035] The front of the frame plate 13 is provided with a fan box 21, and the inside of the fan box 21 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com