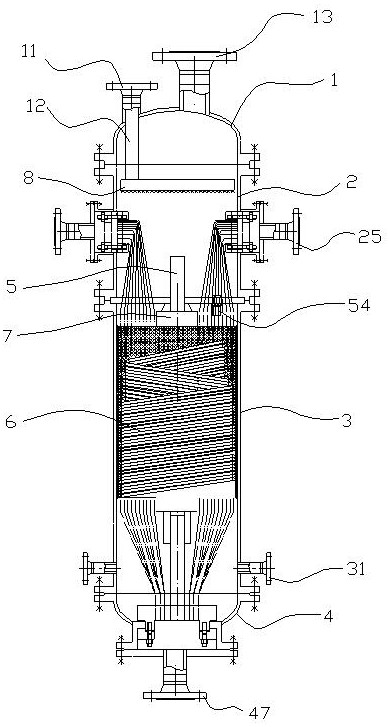

A detachable self-stretching falling film evaporator

A falling film evaporator and evaporator technology, applied in evaporation, chemical instruments and methods, separation methods, etc., can solve problems such as foam, long maintenance time, difficult disassembly, etc., and achieve the effect of increasing heat exchange area and improving evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This example uses figure 1 The falling film evaporator shown in the figure can perform falling film evaporation, which can be a high-pressure occasion, such as the shell side pressure is 3MPa, and the effect obtained is: under the same internal volume of the falling film evaporator, the falling film evaporator of the present invention has a unit time The evaporation capacity is 2 to 6 times that of the existing vertical tube falling film evaporator, and 2 to 8 times that of the existing horizontal tube falling film evaporator, and during operation, it is not easy to appear "dry evaporation of the heat exchange tube" question.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com