Two-claw cylinder clamping jaw mechanism for round piece

A gripper and cylinder technology, applied in the field of automation equipment, can solve the problems of easy collision, reduced equipment movement speed, high cost of force sensor hardware, etc., to achieve the effect of high reliability and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

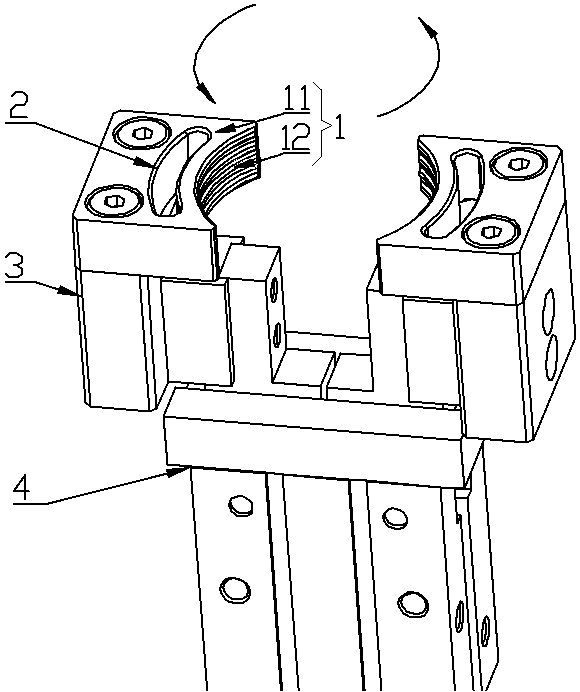

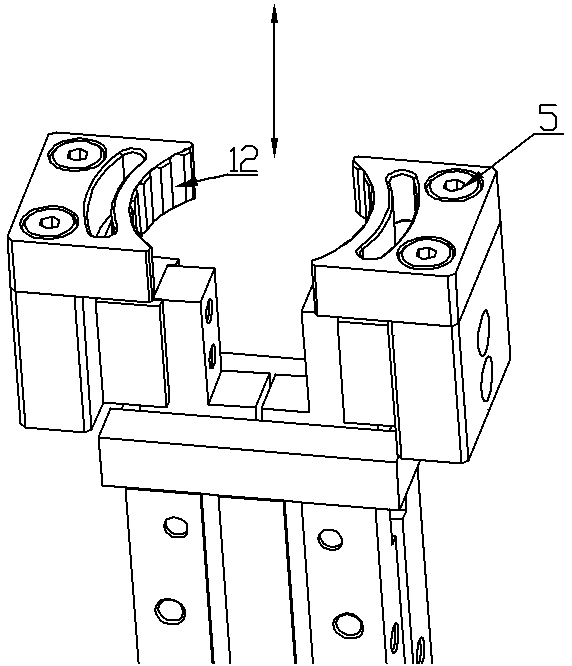

[0021] A two-claw cylinder clamping mechanism for round parts, including a clamping jaw 1, the clamping jaw 1 is composed of two clamping jaw main bodies 11, and the opposite surfaces of the two clamping jaw main bodies 11 are clamping surfaces 12, The jaw main body 11 is respectively arranged on the two action ends of the two-jaw cylinder 4, and the relative distance between the clamping surfaces 12 on the two jaw main bodies 11 is changed by the two-jaw cylinder 4 for gripping.

[0022] The gripping surface 12 is an arcuate surface with inner grooves, and the jaw main body 11 on the rear side of the gripping surface 12 is provided with a crescent groove 2, which conforms to the principle of bionics.

[0023] The radian of the crescent groove 2 is set concentrically with the radian of the clamping surface 12 .

[0024] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com