Concrete finished product hopper combined discharge valve

A discharge valve and concrete technology, which is applied in the direction of cleaning hollow objects, clay preparation devices, control devices, etc., can solve the problems of inconsistent height, falling on the ground, and splashing of concrete slurry, so as to improve fluidity and reduce stickiness. Attachment, the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

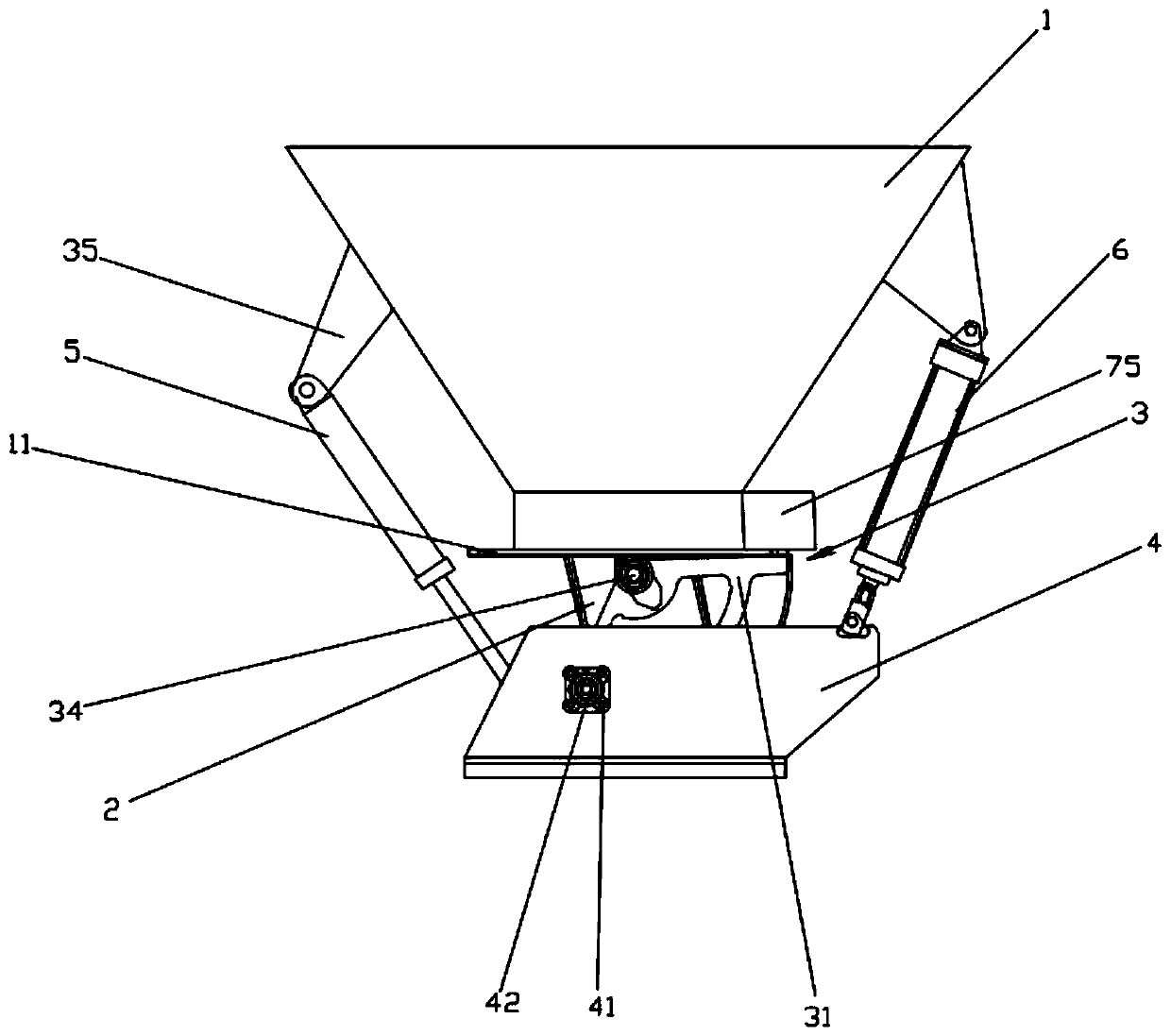

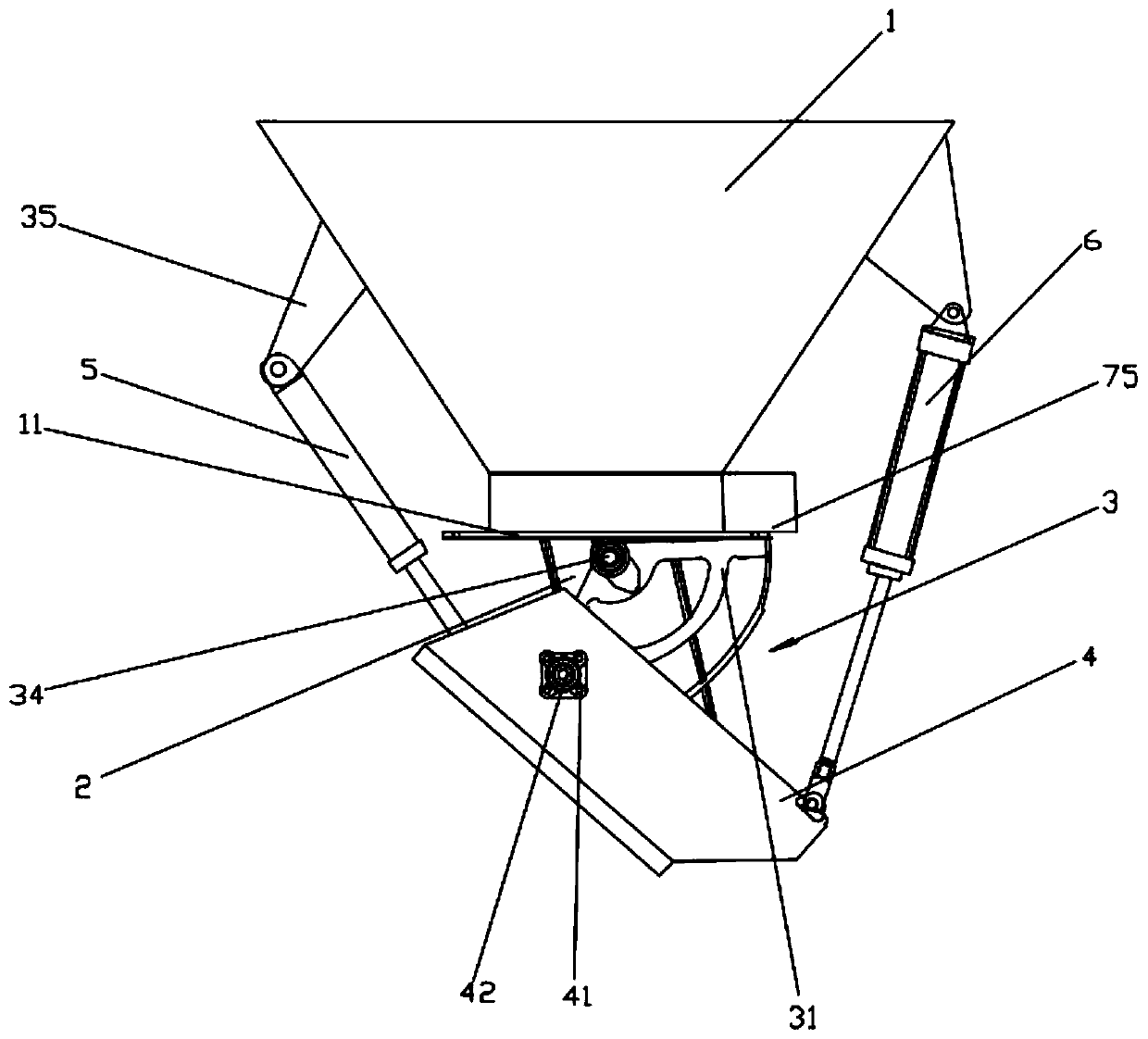

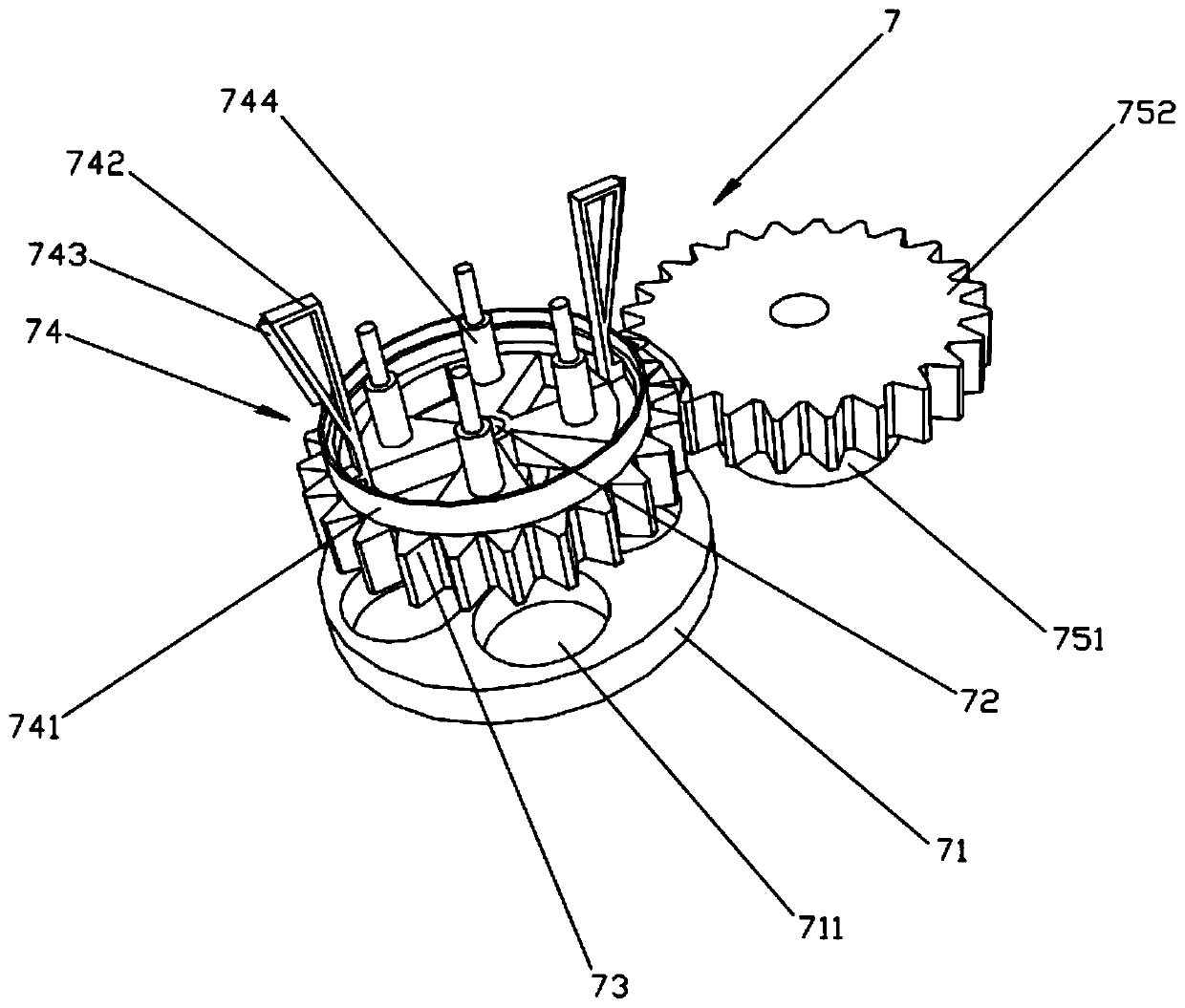

[0026] Such as Figure 1-7 As shown, it is a combined unloading valve for a concrete finished hopper in this embodiment, which includes a raw material hopper 1 and a vertical unloading valve 2 arranged up and down in sequence. The bottoms are all open, the lower end of the raw material hopper 1 is connected with the top of the vertical discharge valve 2 through the flange 11, and the outer peripheral side of the vertical discharge valve 2 is provided with an arc-shaped valve plate 3 and a movable Chute 4, arc valve plate 3 comprises left side plate 31, right side plate 32 and arc bottom plate 33, left side plate 31 and right side plate 32 are fan-shaped hollow structures, the circle center of left side plate 31 and right side plate 32 Each of them is connected to the opposite outer wall of the vertical discharge valve 2 through the rotating shaft 34 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com