Mechanical supercharger

A mechanical supercharger and blade technology, applied in mechanical equipment, machines/engines, rotary piston machines, etc., can solve the problems of connection, inability to close the profile, low compression, etc., to improve the diameter to distance ratio, improve the use Power and rotational torque, and the effect of improving the area utilization factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

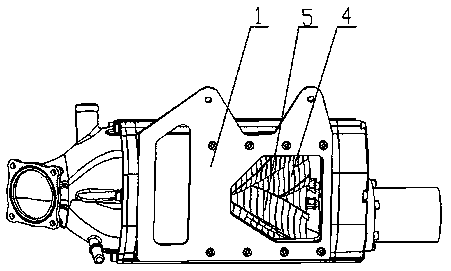

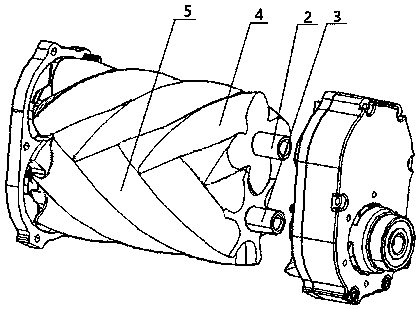

[0033] Such as Figure 1 to Figure 3 An embodiment of a supercharger of the present invention is shown, including a supercharger housing 1 and a first rotating shaft 2 and a second rotating shaft 3 placed in the supercharger housing 1, the first rotating shaft The first rotor mechanism 4 is set on the top of the 2, and the second rotor mechanism 5 is set on the second rotating shaft 3. The first rotor mechanism 4 and the second rotor mechanism 5 mesh with each other as the first rotating shaft 2 and the second rotating shaft 3 rotate. ;

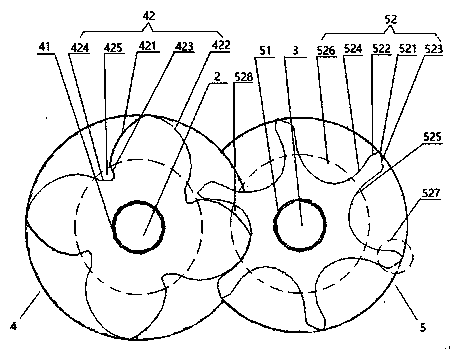

[0034] The first rotor mechanism 4 includes a first rotor body 41 and a plurality of first blades 42 protruding outwards placed on the first rotor body 41, the plurality of first blades 42 are evenly distributed, and the plurality of first blades 42 are formed by the first One end of the rotor body 41 extends to the other end to form a helical structure, and the first blade 42 includes a left involute 421, a right involute 422, a left root 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com