Anti-corrosion corrugated pipe for natural gas conveying

A bellows, natural gas technology, applied in the field of bellows, can solve the problems of corrosion, easy to produce cracks, poor pressure resistance, etc., and achieve the effect of preventing natural gas leakage and improving the degree of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

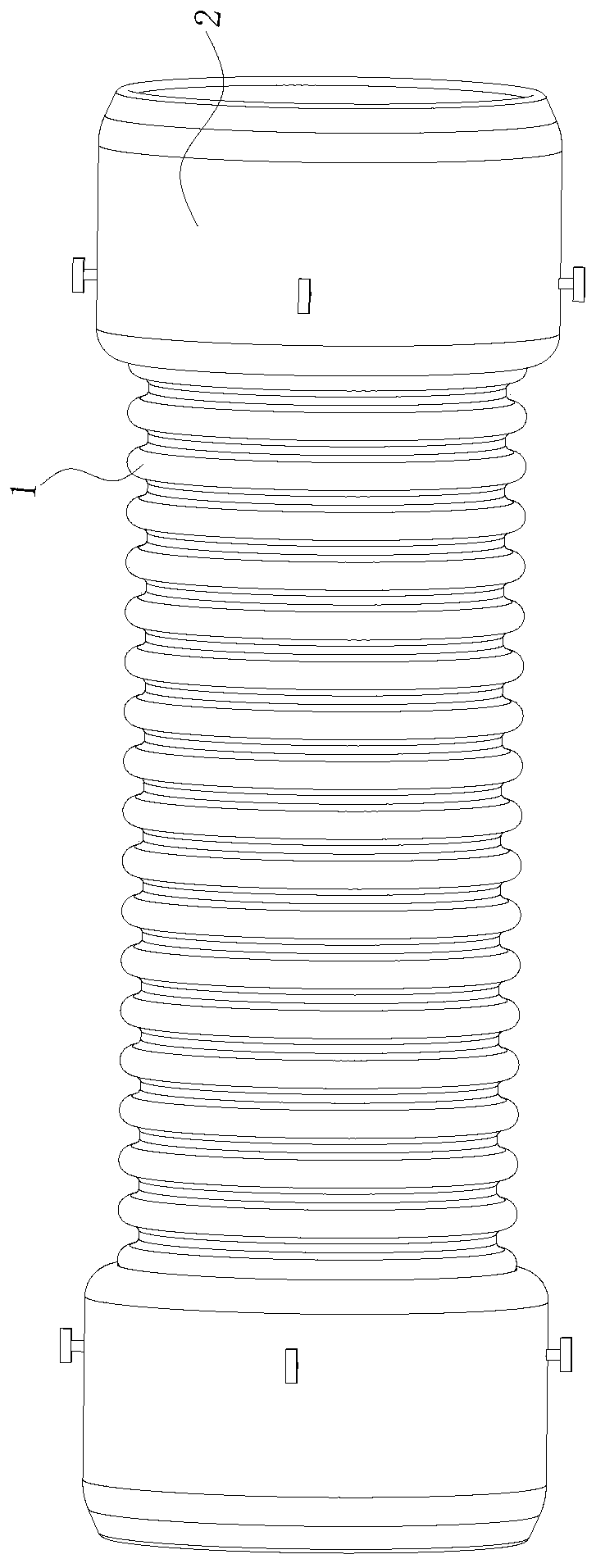

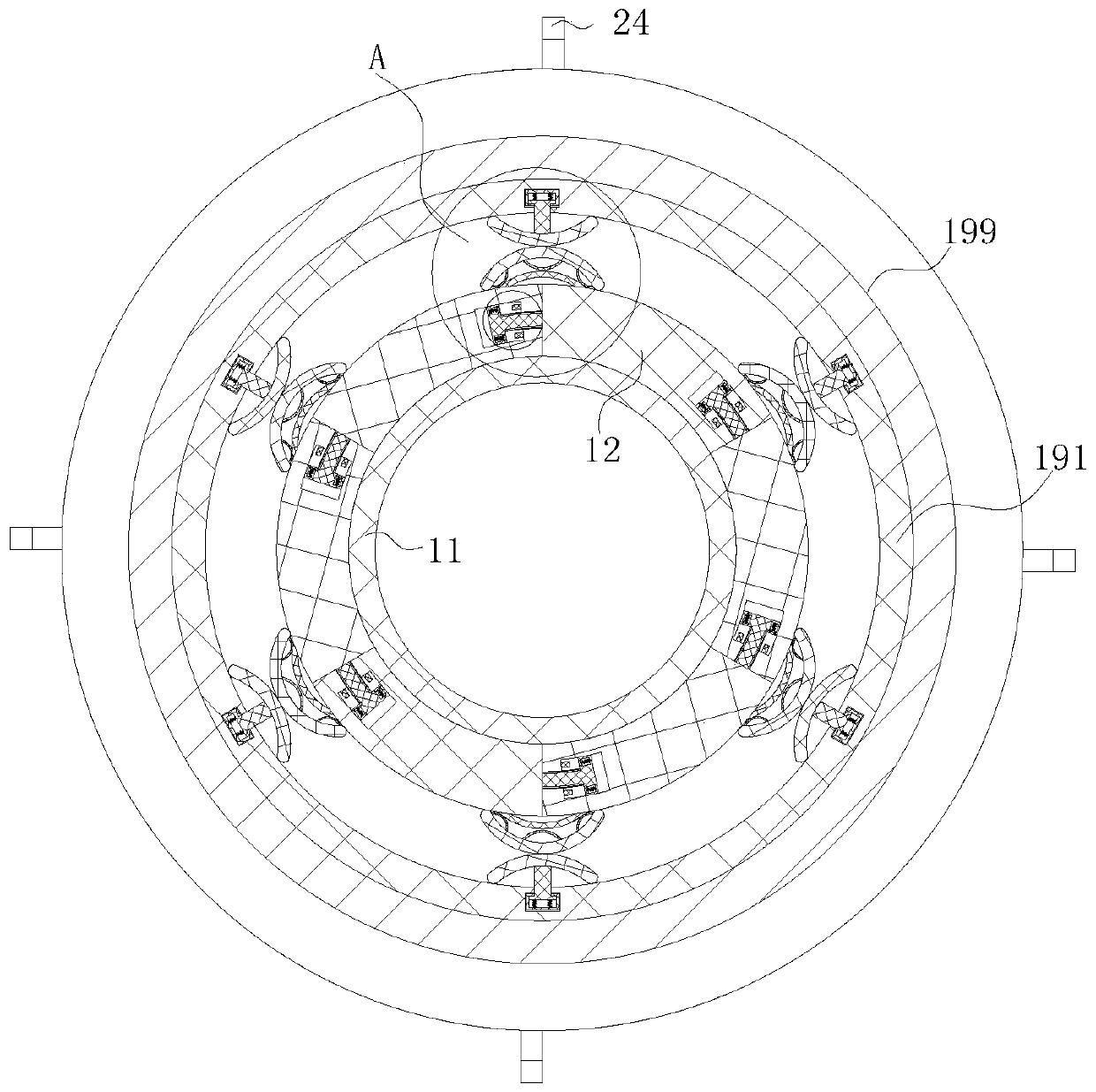

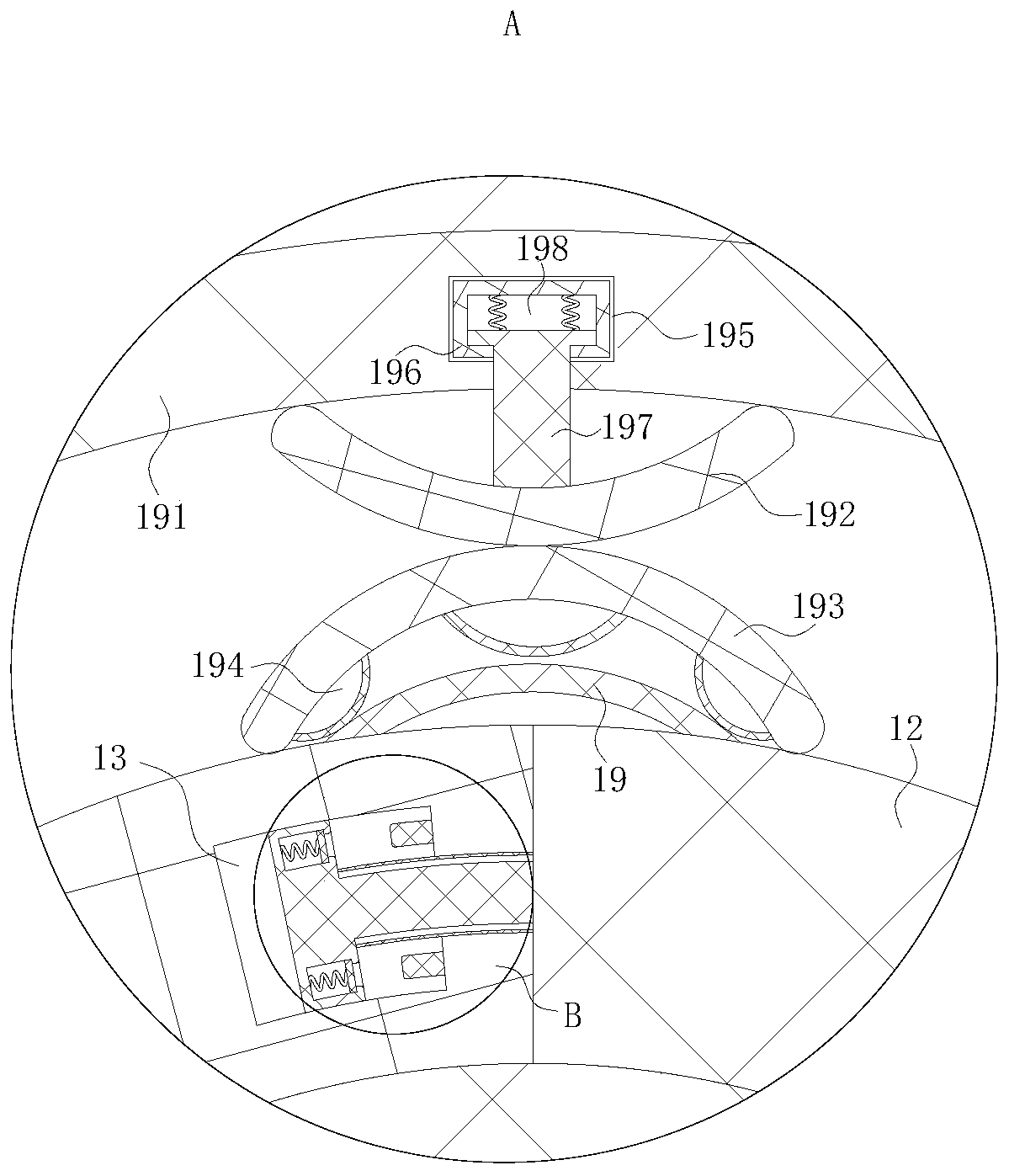

[0023] use Figure 1-Figure 6 An anti-corrosion corrugated pipe for natural gas transportation according to an embodiment of the present invention is described as follows.

[0024] Such as Figure 1-Figure 6 As shown, a corrosion-resistant corrugated pipe for natural gas transportation according to the present invention includes a long pipe 1 and a joint 2; the outer surface of the long pipe 1 is sleeved with joints 2 at both ends of the long pipe 1; the long pipe 1 includes an elastic hose 11; the elastic hose 11 is made of anti-corrosion material; the outer surface of the elastic hose 11 is fixed with evenly arranged arc-shaped blocks 12, and the evenly arranged arc-shaped blocks 12 are attached to each other Form a round tube; each of the arc-shaped blocks 12 one side end surface is provided with a first slide groove 13; The blocks 14 are all placed in the first chute 13 and are slidably connected with the first chute 13; each of the arc-shaped blocks 12 is fitted with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com