Model rocket convenient to recycle

A model rocket and rocket technology, applied in the field of models, can solve the problems of insufficient resistance, waste of reusable resources, uncontrollability, etc., to reduce the impact force of landing, reduce the risk of crash, and realize the effect of installation function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

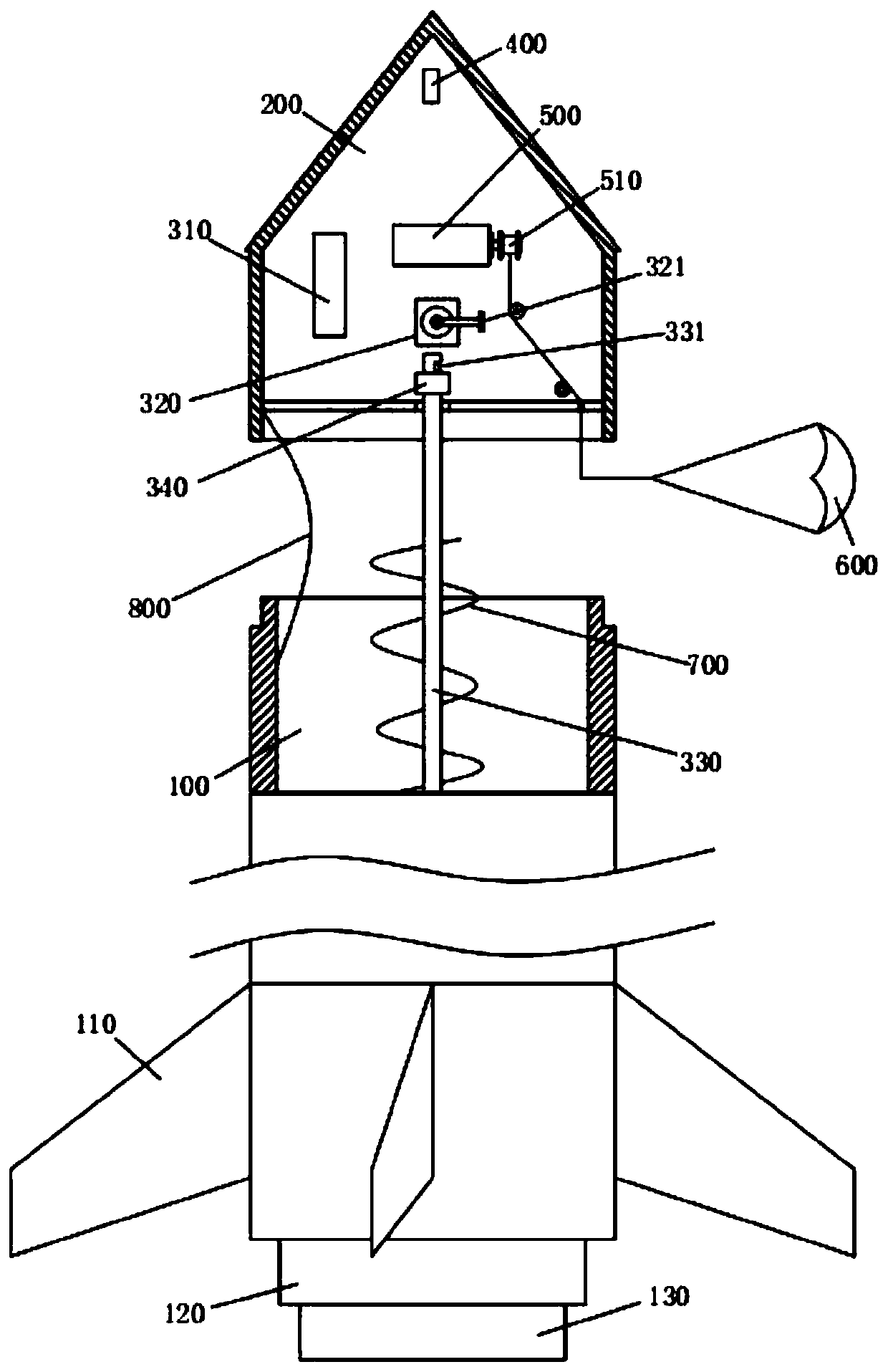

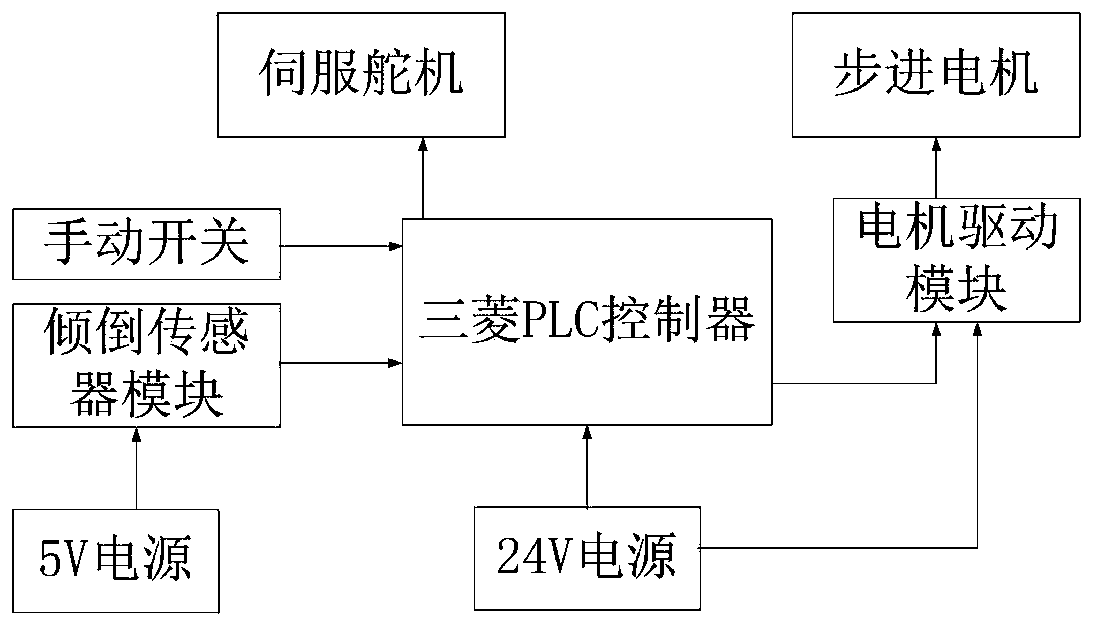

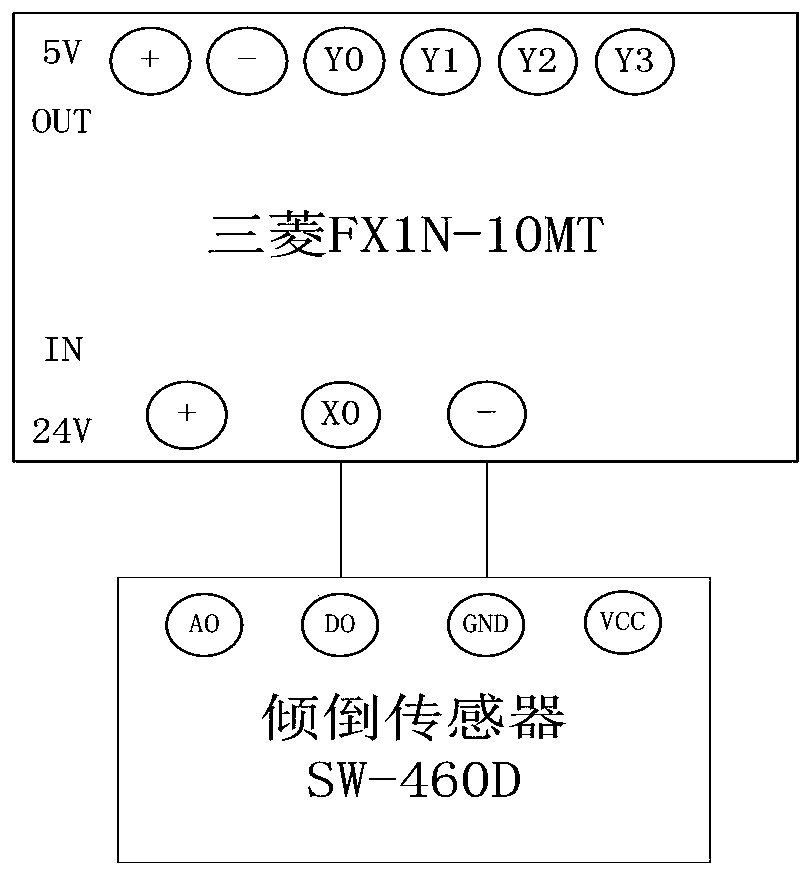

[0035] refer to Figure 1-5 , in this embodiment, a model rocket that is easy to recover is proposed, including an arrow 200 and an arrow body 100, a sensor 400 and a parachute 600 are installed in the arrow 200, and the sensor 400 is connected with the adjustment mechanism. During the rocket operation, the adjustment mechanism adjusts the arrow The 200 is in two states, one is: the rocket is in an upright posture when it lifts off, and when the sensor does not detect the change of the rocket's posture, the adjustment mechanism adjusting the arrow 200 is in the working state of being assembled on the rocket body 100, and the other is: when the rocket falls When the attitude changes, the sensor detects the change in the attitude of the rocket, and the adjusting mechanism adjusts the arrow 200 according to the signal detected by the sensor to be in a disengaged state in which the rocket body 100 releases the parachute 600 .

[0036]Through the setting of the sensor 400 and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com