LED support, LED luminescent device and LED display screen

A technology for LED brackets and light-emitting devices, which is applied to semiconductor devices, instruments, electrical components, etc., can solve the problems of lack of protection for welding sections, reduce the versatility of light-emitting devices, and deformation, so as to promote welding effects and avoid direct heating. Yellowing, The effect of widening the range of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

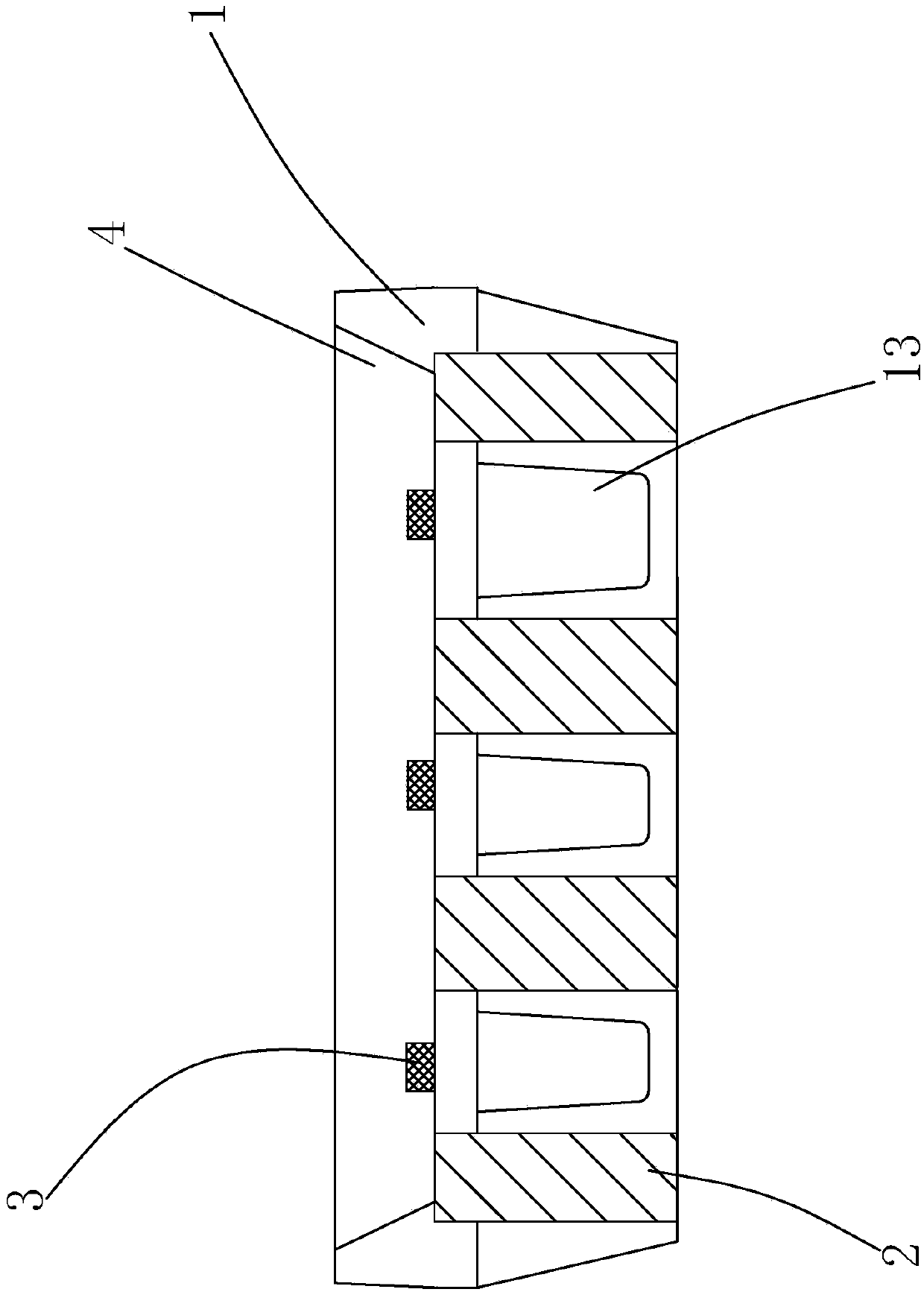

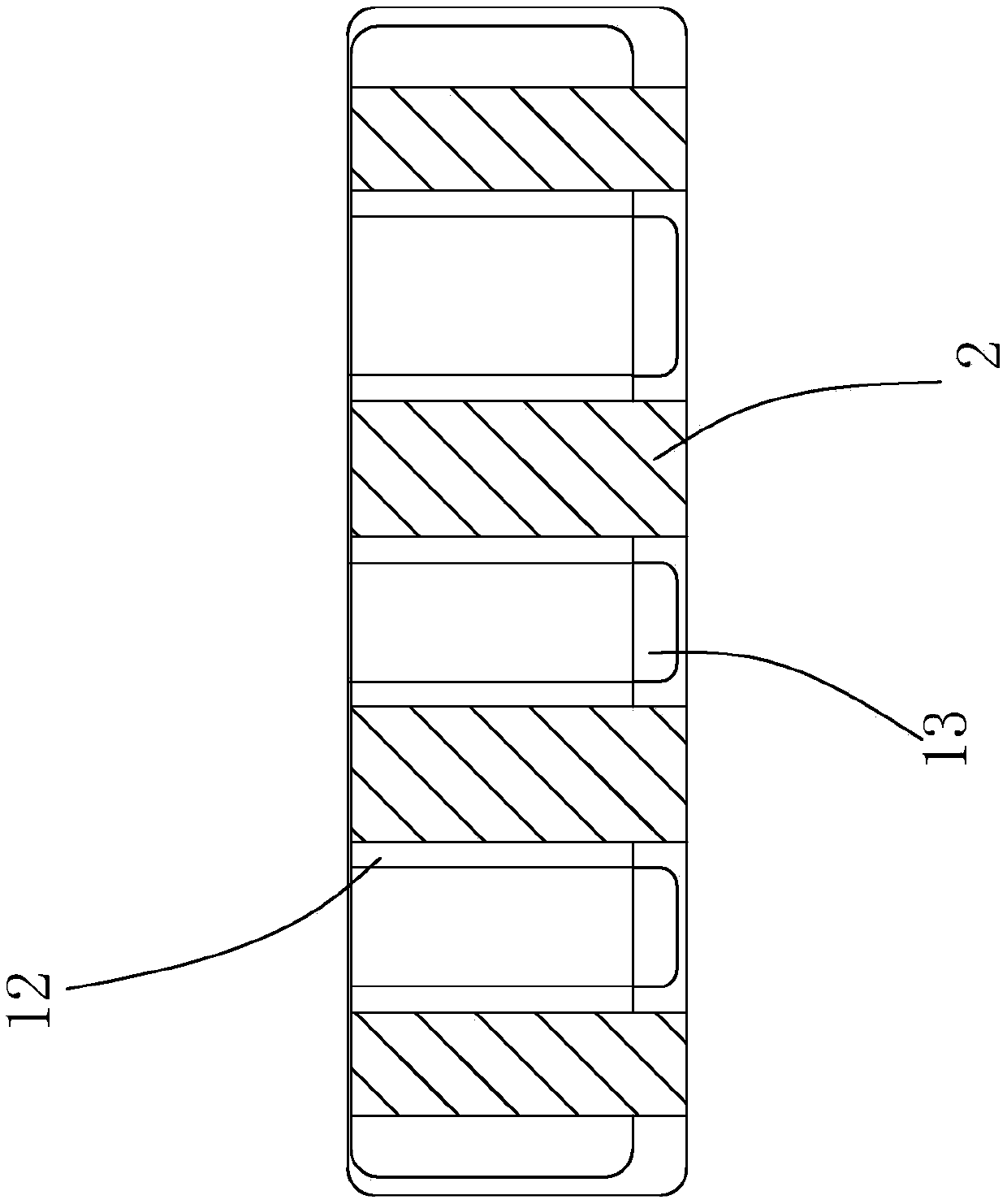

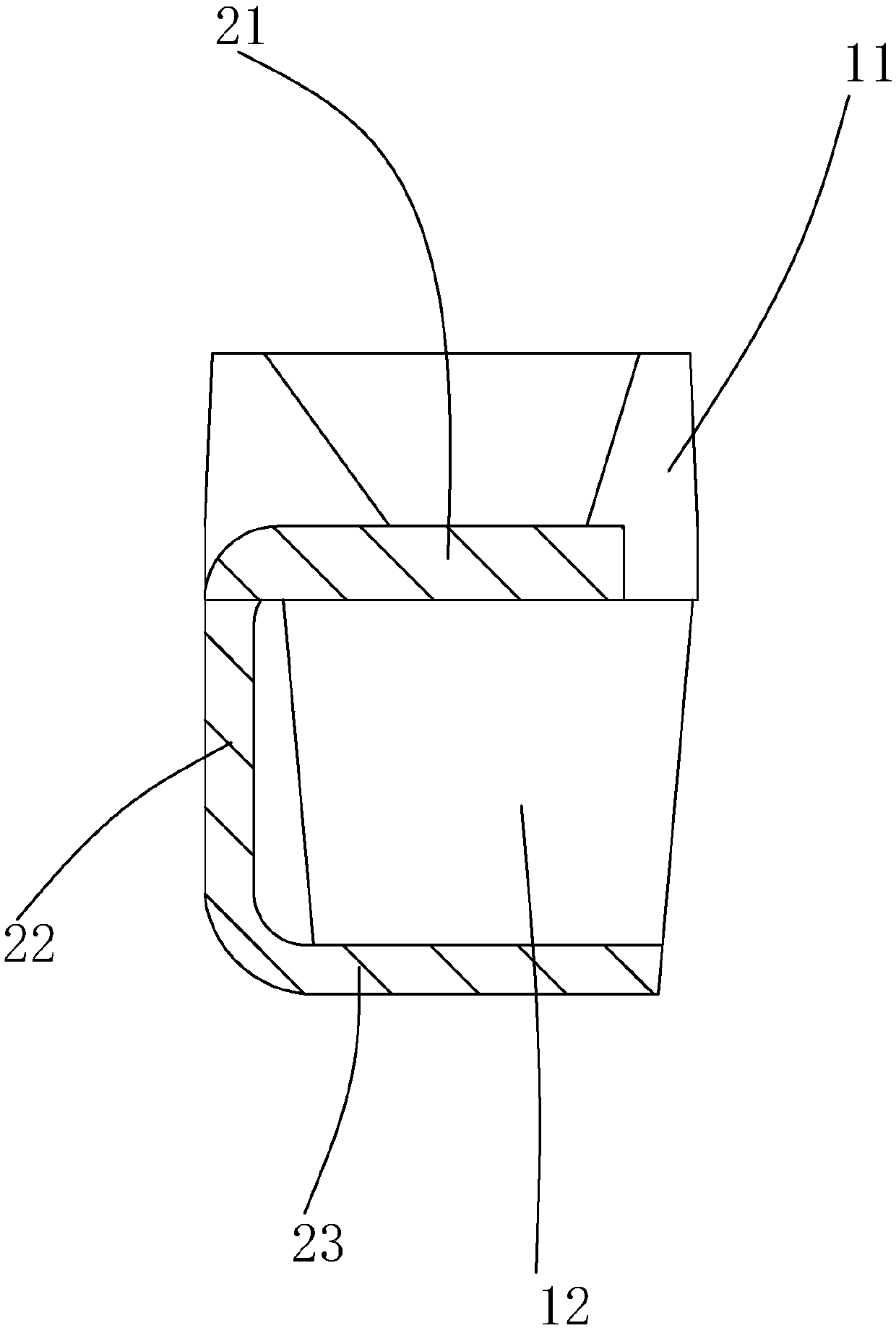

[0024] Example 1: Reference Figure 1 ~ Figure 3 , An LED bracket, comprising a cup cover 1, a metal pin 2, the cup cover 1 including a reflective cup 11, a base 12, the metal pin 2 has more than two, the metal pin 2 includes chip placement Section 21, the vertical welding section 22 and the horizontal welding section 23, all the vertical welding sections 22 of the metal pins 2 are located on the same side of the cup cover 1, and the upper end of the vertical welding section 22 is connected to the chip placement section 21 The lower end is connected to the horizontal welding section 23, the chip placement section 21 is located in the reflector cup 11, the vertical welding section 22 is located outside the side surface of the base 12, and the horizontal welding section 23 is located on the bottom surface of the base 12. Down side.

[0025] By arranging all the vertical welding sections on the same side of the cup cover, when the device is used for side-emitting light, the vertica...

Embodiment 2

[0030] Example 2: see Figure 4 When there are four metal pins, two of the metal pins will be located on the outermost side of the cup cover. As a further preferred embodiment, the base 12 further includes an external partition 14, the external partition 14 Located on the outermost side of the side, that is, on the side of the outermost metal pin. That is to say, an external barrier is provided at each of the two edges of the cup cover to prevent the outermost metal pins from falling off. There should also be a gap between the external barrier and the metal pins, and the range of the gap is also 0.02mm- 0.2mm, preferably 0.08mm-0.12mm.

Embodiment 3

[0031] Example three, see Figure 5 , The side of the base 12 provided with the vertical welding section 22 is a first side, the base 12 also includes a second side opposite to the first side, and the metal pin 2 also includes a balance Section 24, the balance section 24 is located at the end of the horizontal welding section 23, and the balance section 24 is located on the second side surface of the base 12. There can also be a barrier between two adjacent balance sections, or a barrier between two adjacent balance sections and between two adjacent horizontal welding sections, or between two adjacent balance sections. Barriers are set between the balance sections, between two adjacent horizontal welding sections and between two adjacent vertical welding sections to block the left and right deviation of the metal pins and improve product stability. In a more preferred embodiment, an external barrier is also provided beside the outermost balance section of the base to prevent th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com