Cutting mechanism for crop topping, topping mechanism and topping vehicle

A technology of cutting mechanism and crops, applied in agricultural machinery and implements, cutting tools, cutting equipment, etc., can solve the problems of slow realization, affecting cotton yield, complex structure, etc., achieve automation, increase jet impact range, and reduce response time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

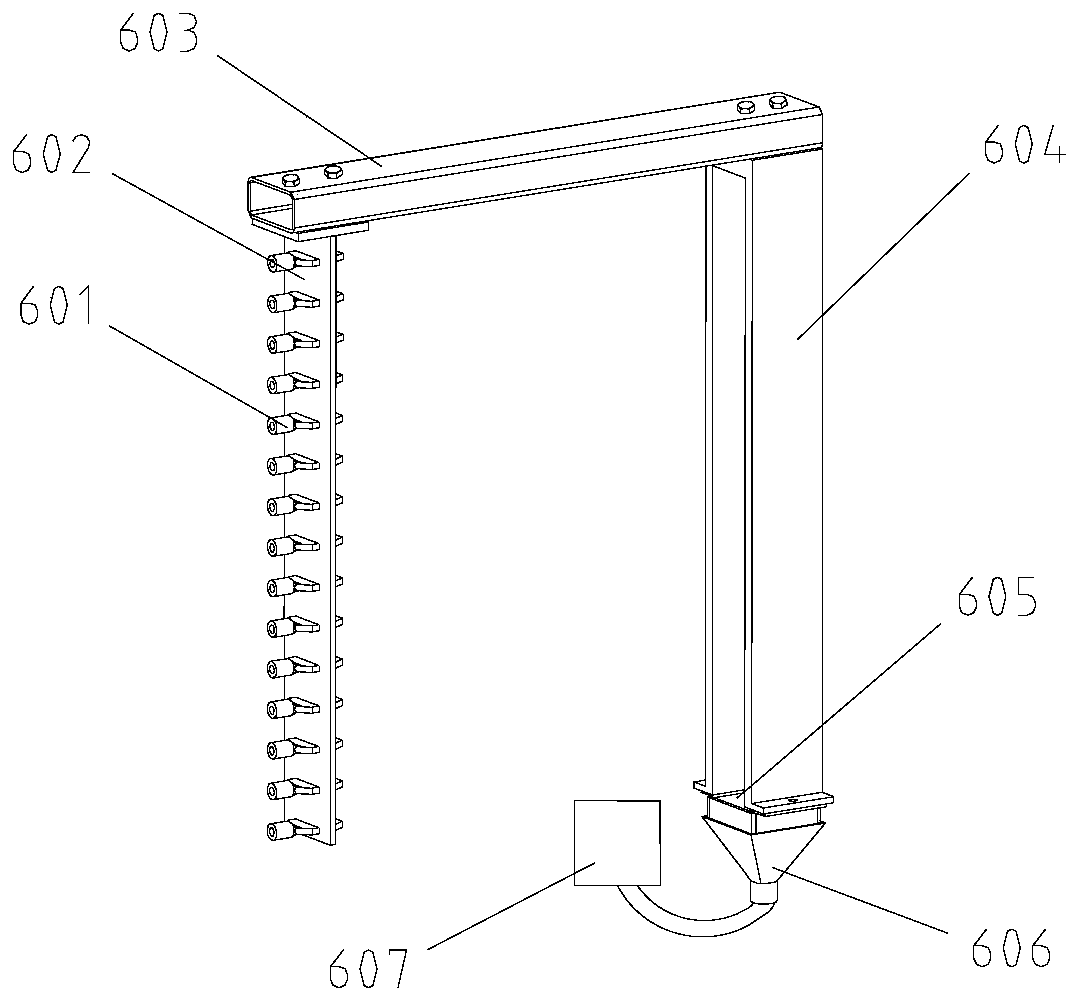

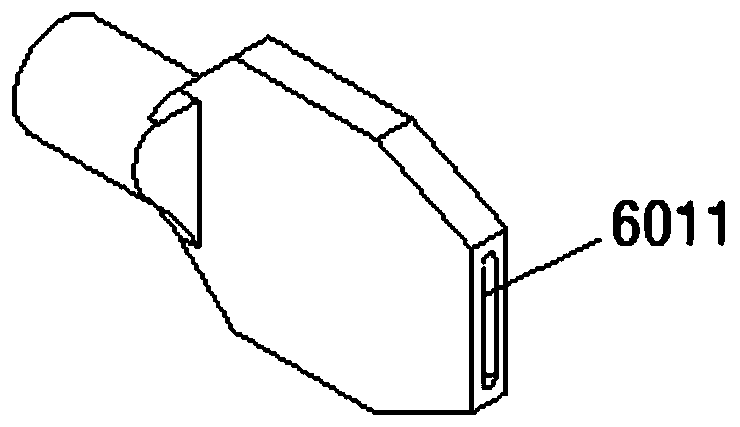

[0032] Such as Figure 1-2 As shown, this embodiment provides a cutting mechanism for topping crops, including a recovery plate and a vertically arranged mounting plate 602, on which a plurality of nozzles 601 are fixed, and the plurality of nozzles 601 are arranged along the vertical direction. Arranged in sequence, the spraying directions of the plurality of nozzles 601 are parallel to each other. Each nozzle 601 can be communicated with the pressure water source respectively, and multiple nozzles 601 are opened and closed independently, so that the nozzles 601 at the set height spray out the pressure water, and the impact of the pressure water can remove the cotton top core at the set height.

[0033] It should be pointed out that in this solution, the mounting plate 602 is in a vertical state during use, and the nozzles 601 are arranged in a vertical direction; if it is not in use for transportation or storage, it may be placed flat or inclined. Therefore, the vertical ar...

Embodiment 2

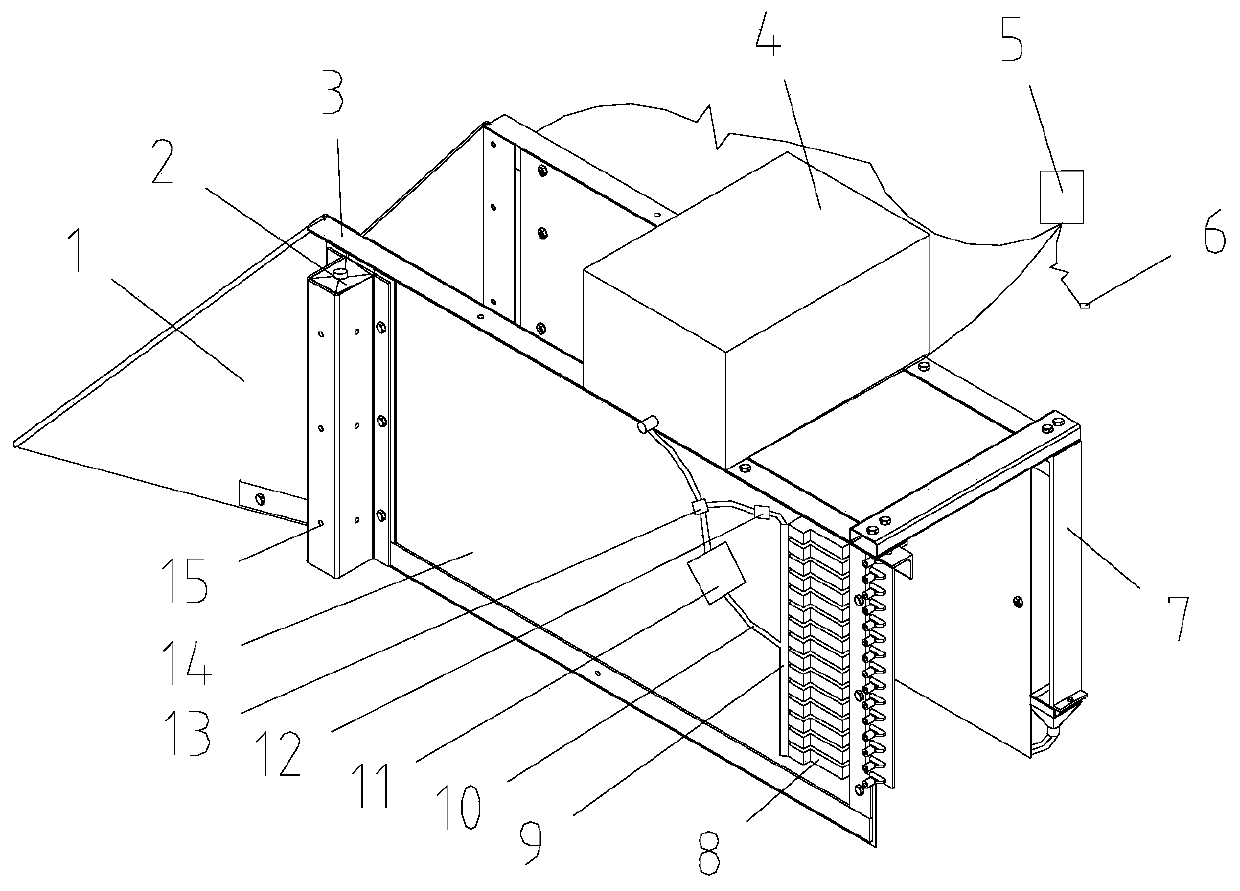

[0041] Such as Figure 3-5As shown, the present embodiment provides a crop topping mechanism, which utilizes the crop topping cutting mechanism, including a frame 3 and a controller 5, the frame 3 can advance along a set direction, and the frame 3 The end close to the forward direction is set as the head end, and the other end is the tail end.

[0042] The mounting plate 602 is fixed on the frame 3 near the tail end, and the height detection sensor 2 is installed near the head end in the frame 3, and the height detection sensor 2 can detect the top core of the cotton passing through this position. high;

[0043] The controller 5 can receive the data information from the height detection sensor 2, and when the mounting plate 602 passes through the current cotton, the controller 5 can control the nozzles 601 of the corresponding height to spray pressure water.

[0044] In this embodiment, the controller can be an FPGA controller, and in some other implementation manners, other...

Embodiment 3

[0057] This embodiment provides a crop topping vehicle, which utilizes the crop topping mechanism, including a chassis, a running mechanism is installed on both sides of the lower part of the chassis, and a plurality of crop topping mechanisms are installed on the upper end of the chassis. Multiple crop topping mechanisms are arranged side by side, and the side-by-side arrangement direction of the multiple crop topping mechanisms is perpendicular to the advancing direction of the chassis;

[0058] The distance between adjacent crop topping mechanisms is adapted to the distance between adjacent rows of cotton plants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com