Stuffing supply system and method for stuffed food production device

A technology of a production device and a supply system, which is applied to the field of filling supply system of a filling food production device, can solve the problems of affecting the automatic operation of food production, labor-intensive, inability to automatically and continuously supply materials, etc., so as to save labor and improve the level of hygiene. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings.

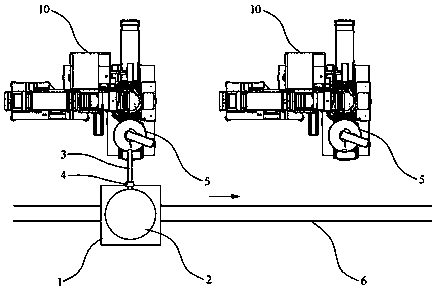

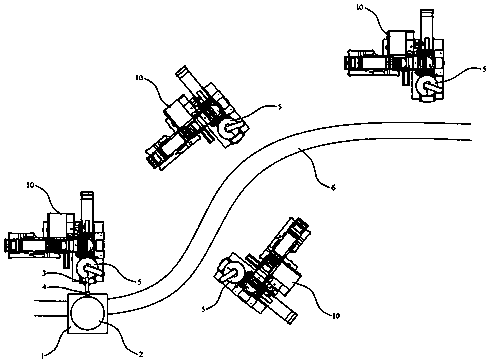

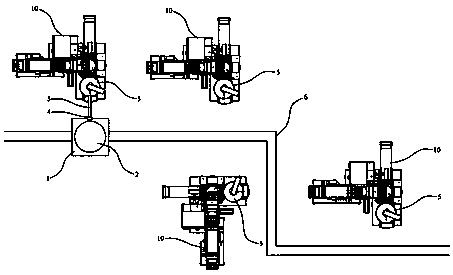

[0025] refer to figure 1 As shown, one embodiment of the present invention is a stuffing supply system for multiple stuffed food production devices. This system is mainly used in the automatic food production production line to solve the cycle of feeding multiple stuffed food production devices. The problem is that the stuffed food production device refers to the automatic production equipment of traditional stuffed food such as dumpling machines, wonton machines, and steamed stuffed bun machines. Compared with similar equipment, this system adopts a more concise model. The core of the system is a movable trolley 1. This trolley is used as a delivery mechanism for fillings and is also used for feeding each stuffed food production device. Feeding mechanism. Specifically, a feeding hopper 2 is installed on the walking trolley 1, and the volume of the feeding hopper 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com