Composite sulfuration improver, preparation thereof and application thereof

A technology of improver and accelerator, applied in the field of vulcanizing agent, can solve the problems of loss of use value of vulcanizing agent, slow vulcanization speed and high decomposition temperature, and achieve the effects of inhibiting blooming phenomenon, reducing vulcanization temperature and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

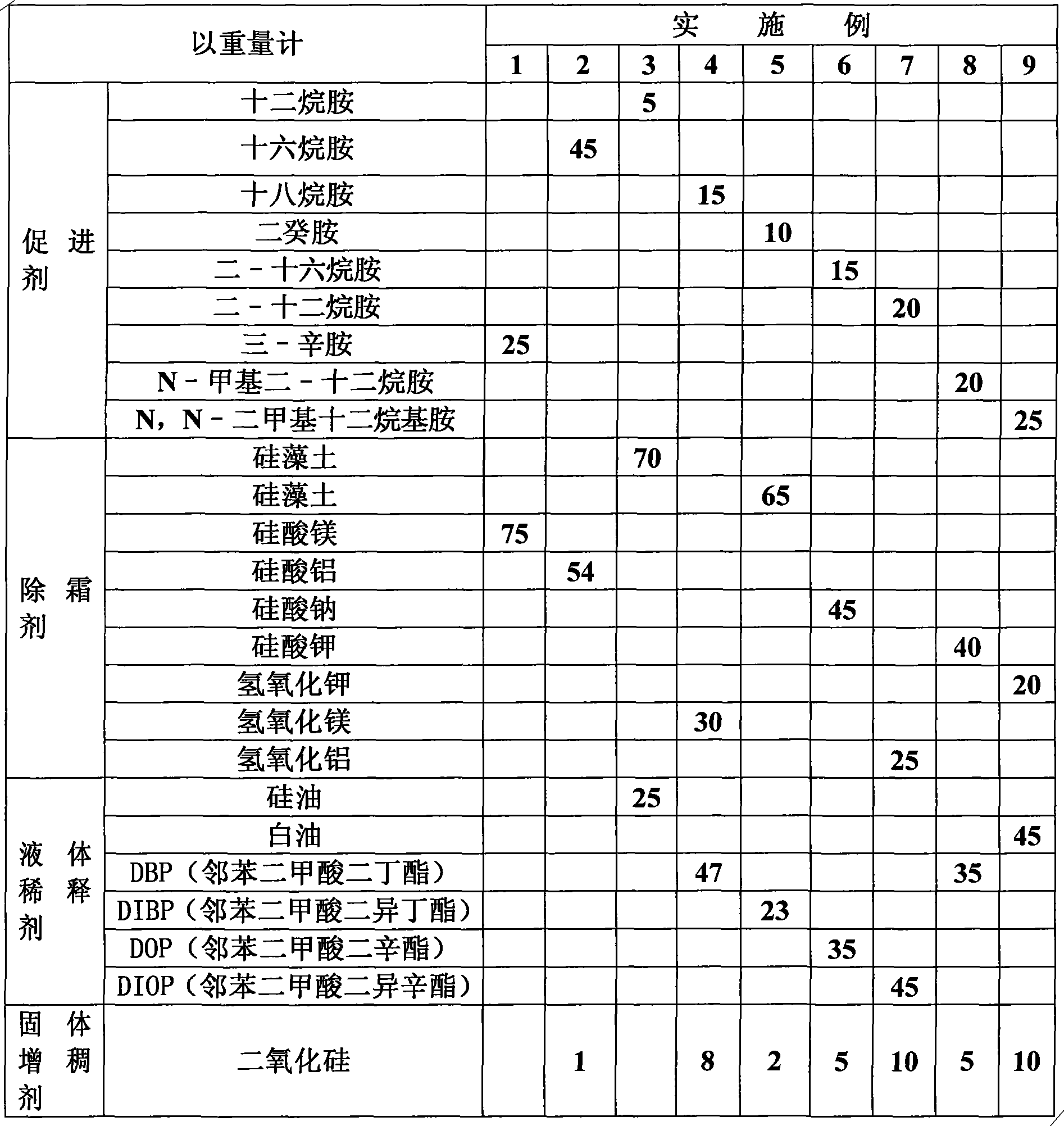

[0014] According to the ratio in the table, add accelerator, defrosting agent, solid thickener and liquid diluent into the kneader, mix thoroughly, and grind evenly to obtain the finished compound vulcanization improver.

[0015] This table is the proportioning of embodiment 1-9 compound vulcanization improver

[0016]

Embodiment 10

[0018] In 100g heat vulcanized silicone rubber compound, add the bis(2,3-dichlorobenzoyl) of 2.5g, after mixing uniformly on the open mill, add the composite vulcanization improver 0.1 that above-mentioned embodiment 1 obtains g, knead again evenly, and the blooming phenomenon changes from the original 1 to 3 weeks of blooming to no frosting at all. Measure the vulcanization characteristics with a rotorless vulcanizer, keep it at 130°C for 8 minutes, and the optimum vulcanization time T 90 Reduced from the original 2.78min to 2.16min, the maximum torque M H From the original 1.216N.m to 1.578N.m.

Embodiment 11

[0020] In 100g heat-vulcanized silicone rubber compound, add 1.8g of bis(3,4-dichlorobenzoyl) peroxide, after mixing uniformly on the open mill, add the compound vulcanization improver 0.05 that above-mentioned embodiment 2 obtains g, knead again evenly, and the blooming phenomenon changes from the original 1 to 3 weeks of blooming to no frosting at all. Measure the vulcanization characteristics with a rotorless vulcanizer, keep it at 130°C for 8 minutes, and the initial vulcanization time is t s1 Reduced from the original 0.42min to 0.34min, the maximum torque M H Increased from the original 1.190N.m to 1.488N.m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com