Movable pulse dust collector and working method thereof

A technology for moving pulses and dust collectors, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve the problems of inflexible transfer of dust collectors, time-consuming and labor-intensive maintenance processes, and increased production costs, so as to improve dust removal. Effect, high degree of automation, safe and reliable service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

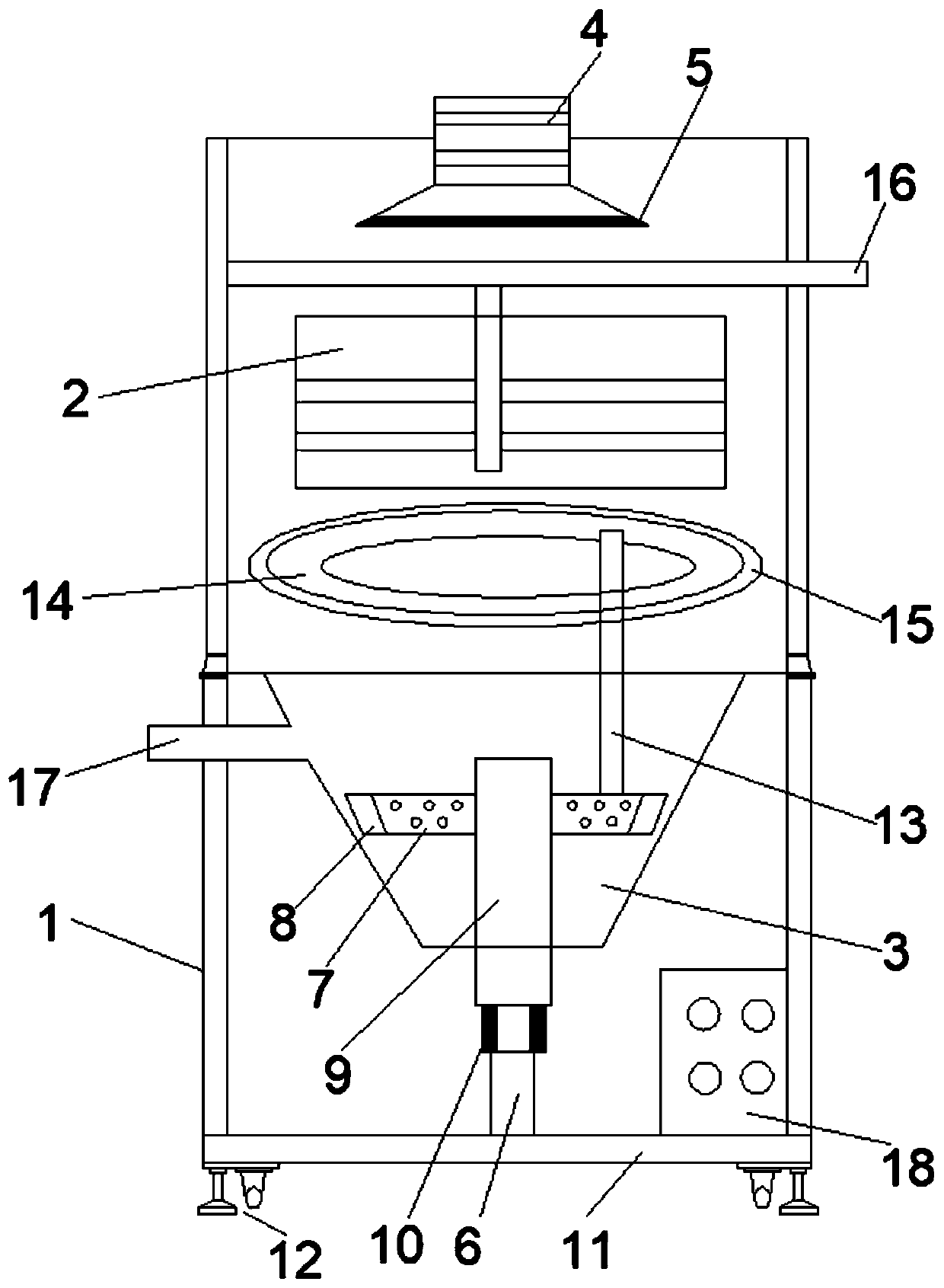

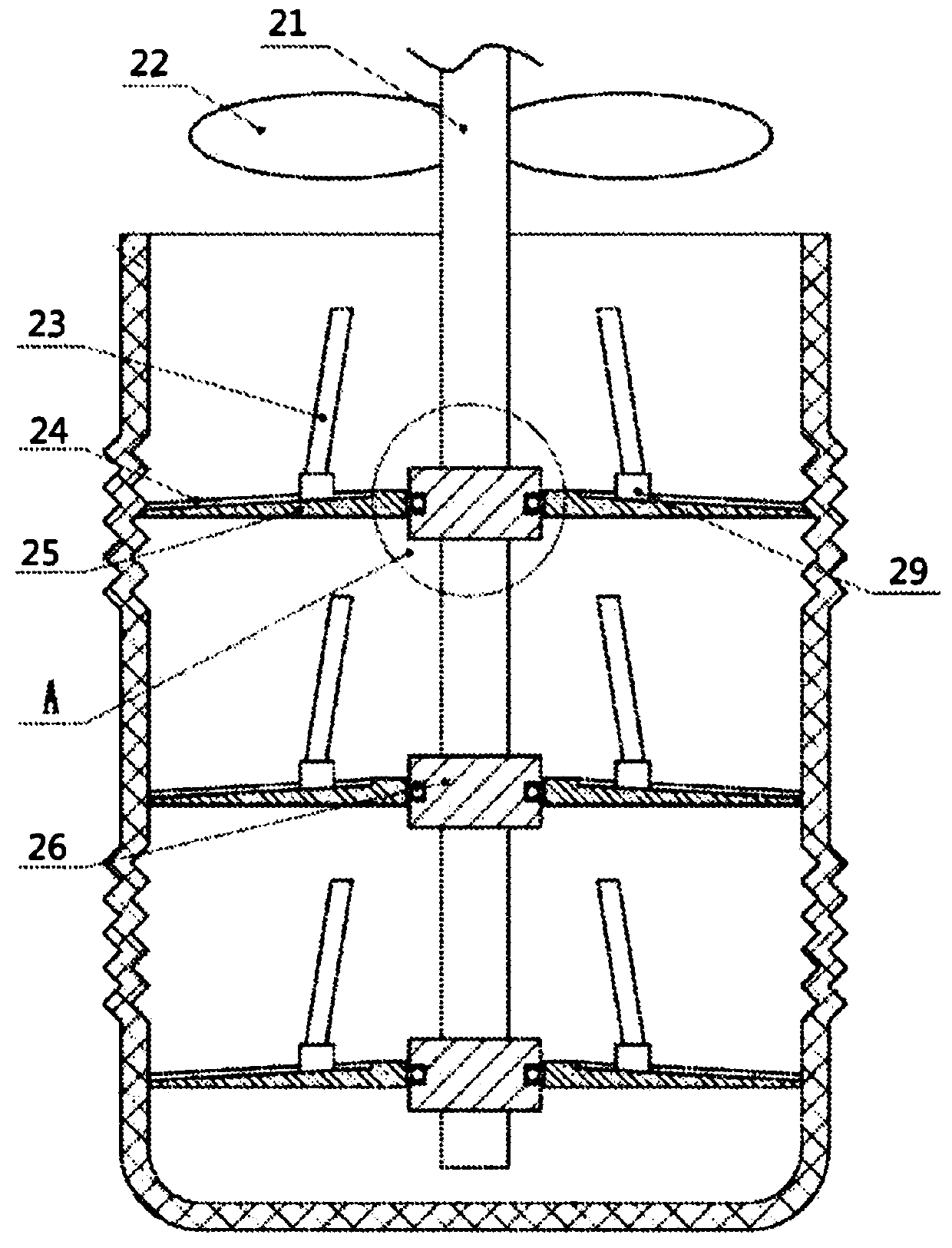

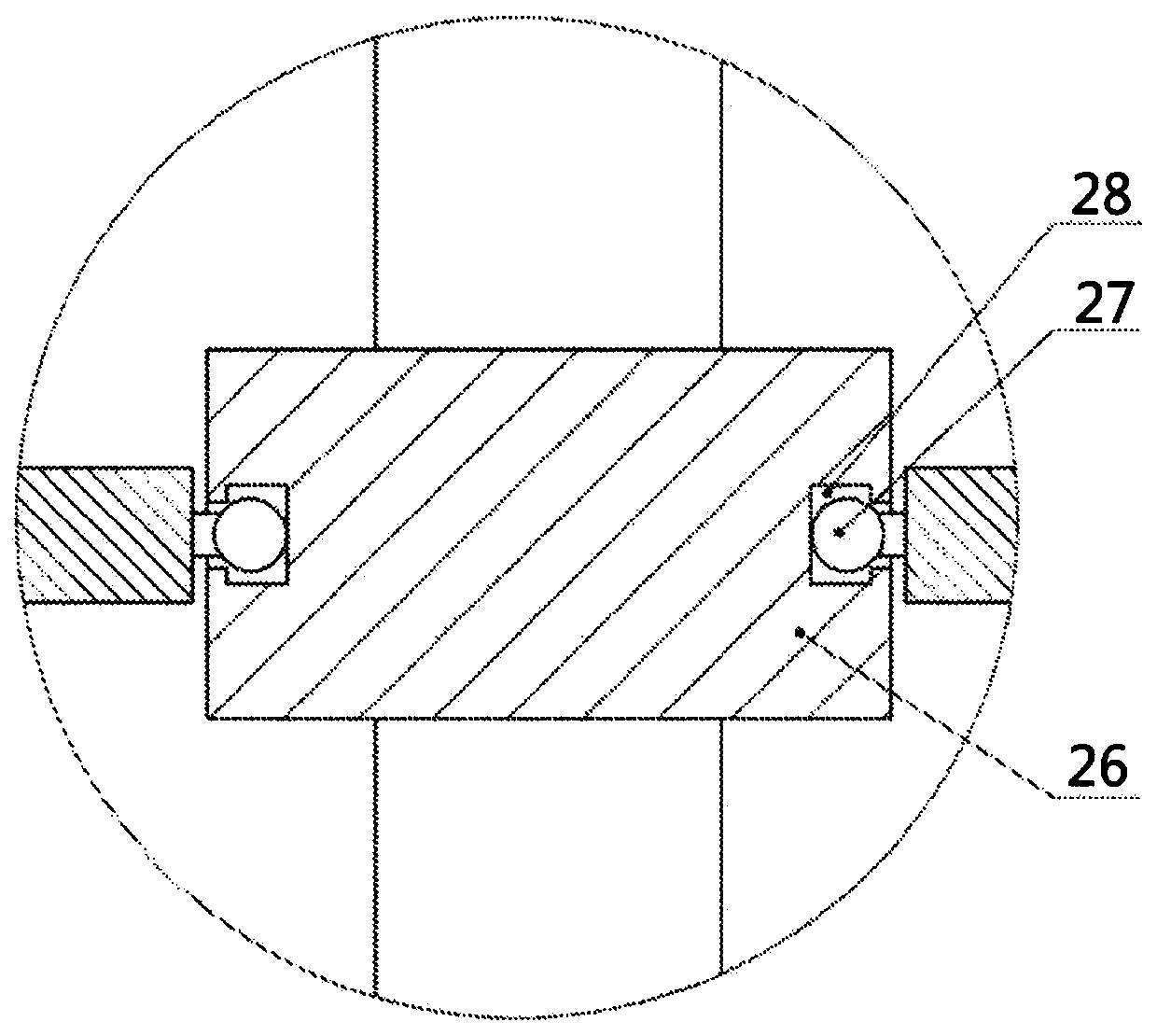

[0028] Such as figure 1 The mobile pulse dust collector shown includes a housing 1, a filter bag device 2, an ash hopper 3, a pulse control valve 4, a moving wheel 12, an air outlet 16, an air inlet 17, a control box 18 and an anti-blocking device. The pulse control valve 4 is set on the top of the shell 1, the filter bag device 2 and the ash hopper 3 are set under the pulse control valve 4 in order from top to bottom, and the air inlet 17 is set on the ash hopper through the shell 1 3 at the top end, the air outlet 16 is set at the side end of the pulse control valve 4, the control box 18 is set at the lower right corner of the casing 1, the bottom of the casing 1 is provided with a base 11, and the moving wheel 12 is set on the base 11 bottom, the anti-blocking device is arranged in the ash hopper 3; wherein, the anti-blocking device includes a screw 9 arranged inside the ash hopper 3, the screw 9 is connected to the motor 6, and the motor 6 is sleeved There is a filter pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com