Coal mine inspection robot platform

A technology for inspection robots and platforms, which is applied in the directions of motor vehicles, elastic suspensions, suspensions, etc., to achieve the effect of simple structure and convenient application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

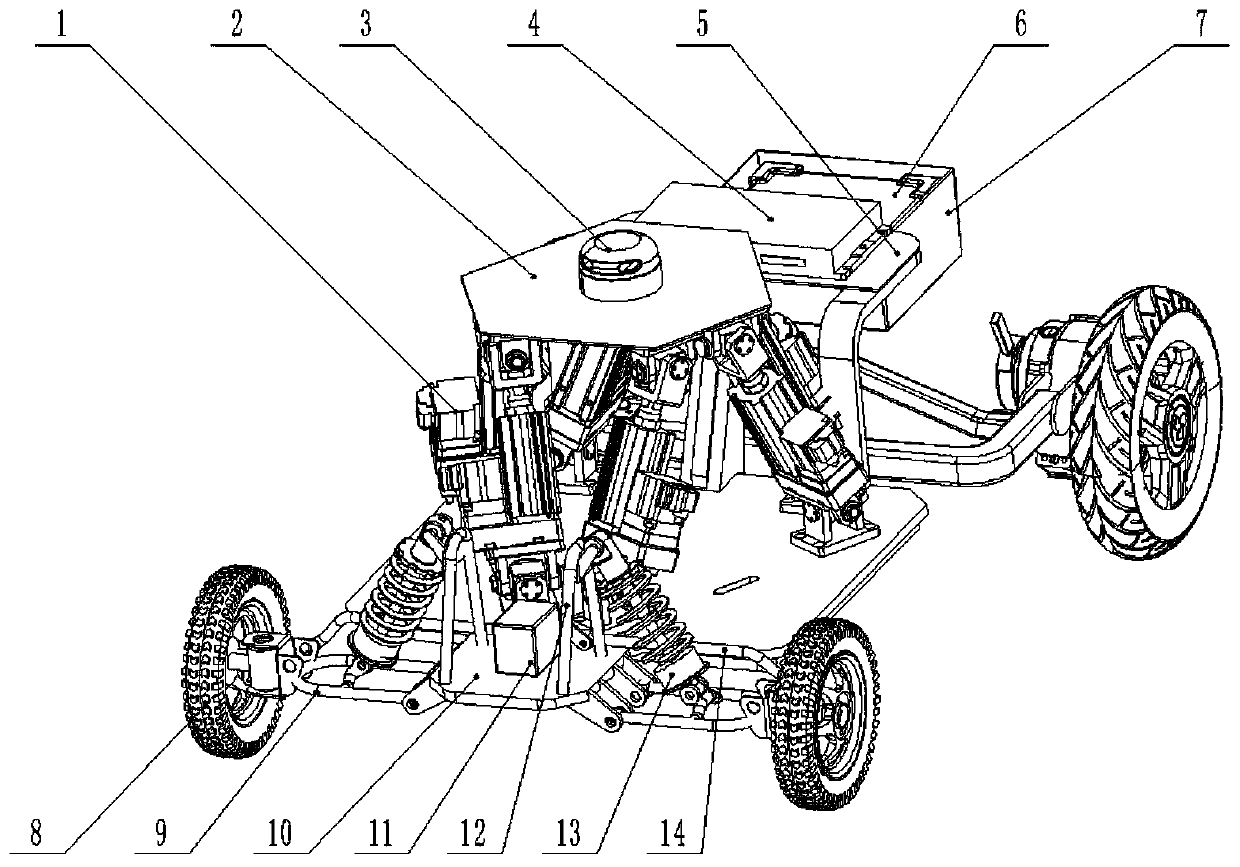

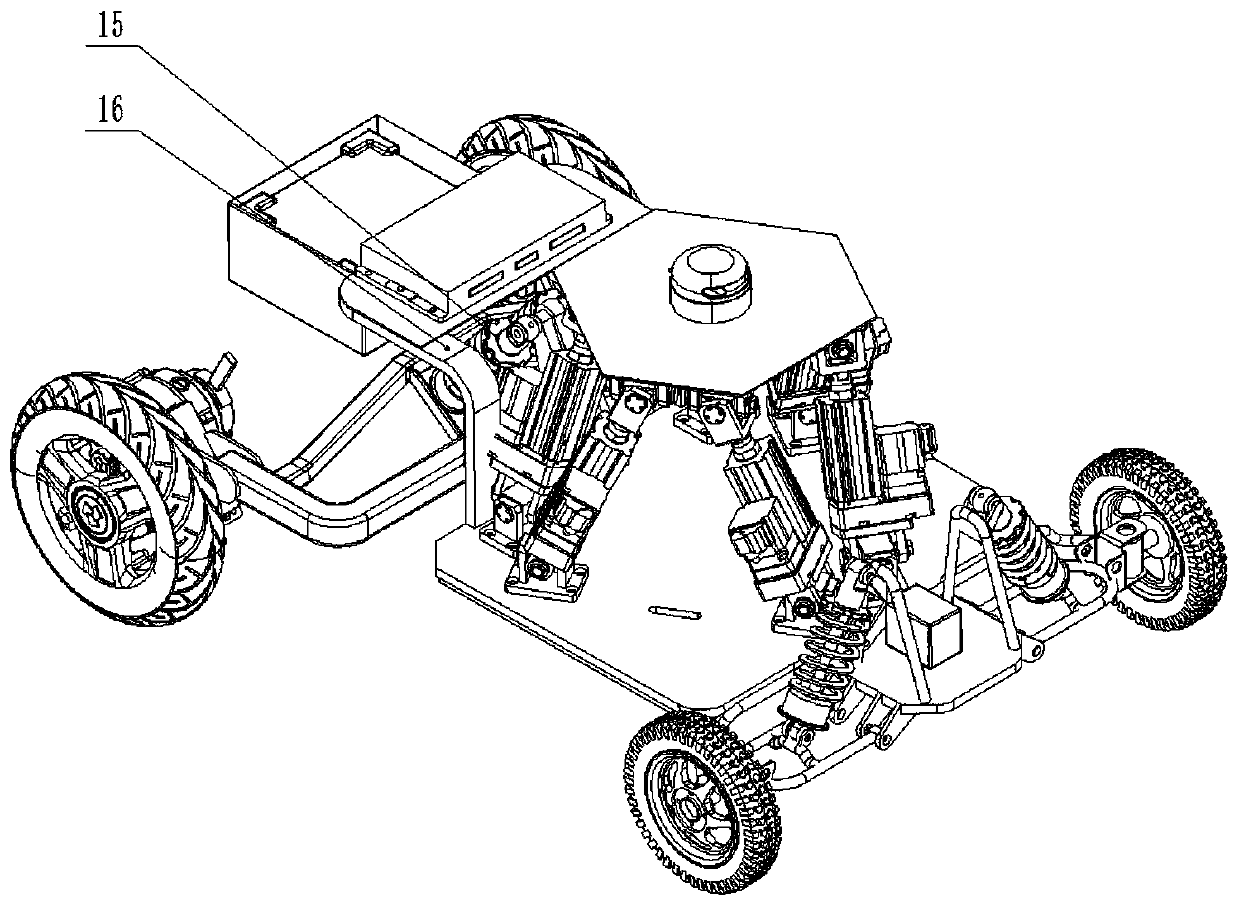

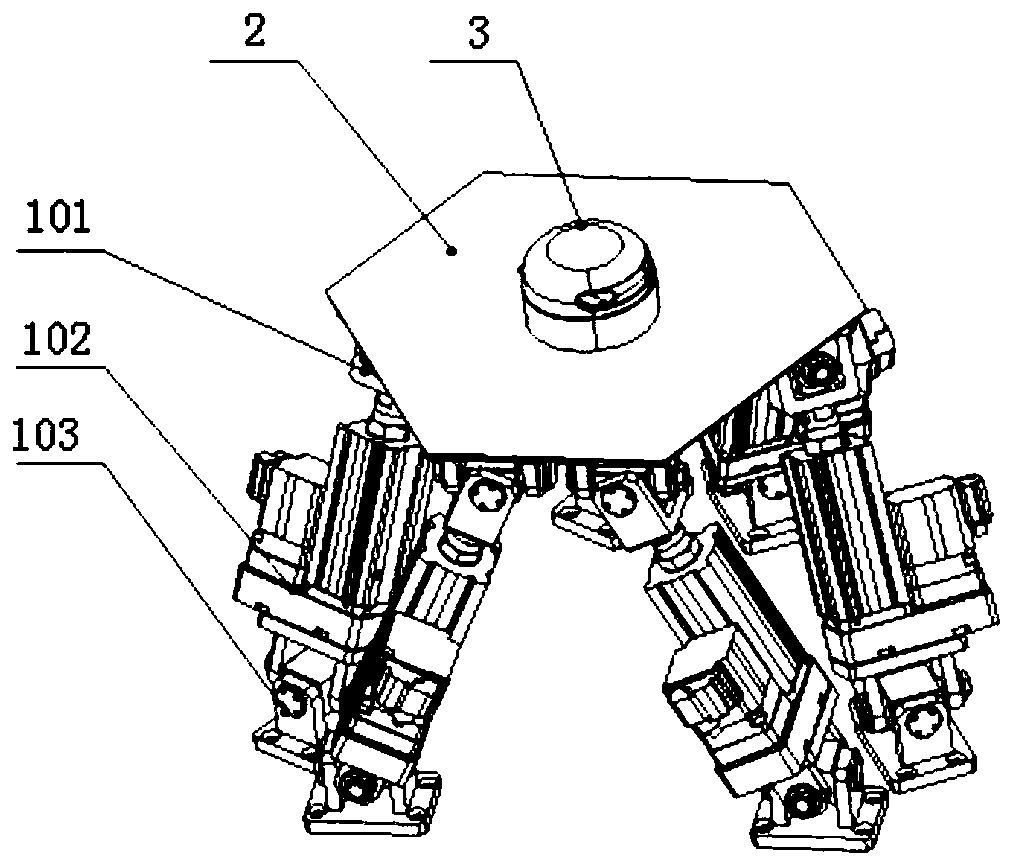

[0016] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the figures referred to, the same or similar components in different figures are denoted by the same reference numerals.

[0017] Such as Figure 1-4 As shown, the coal mine inspection robot platform provided by the present invention includes a six-degree-of-freedom platform 1, a top plate 2, a laser radar sensor 3, a controller 4, a controller board 5, a lithium battery 6, a battery placement box 7, a front wheel 8, and a front wheel 8. Wheel bracket 9, base plate 10, steering motor 11, front shock absorber connecting frame 12, front shock absorber spring 13, steering connecting rod 14, rear shock absorber spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com