Self-positioning pallet mechanism

A self-positioning and pallet technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of small adjustable range, unfavorable fine-tuning of pallet lifting stroke, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

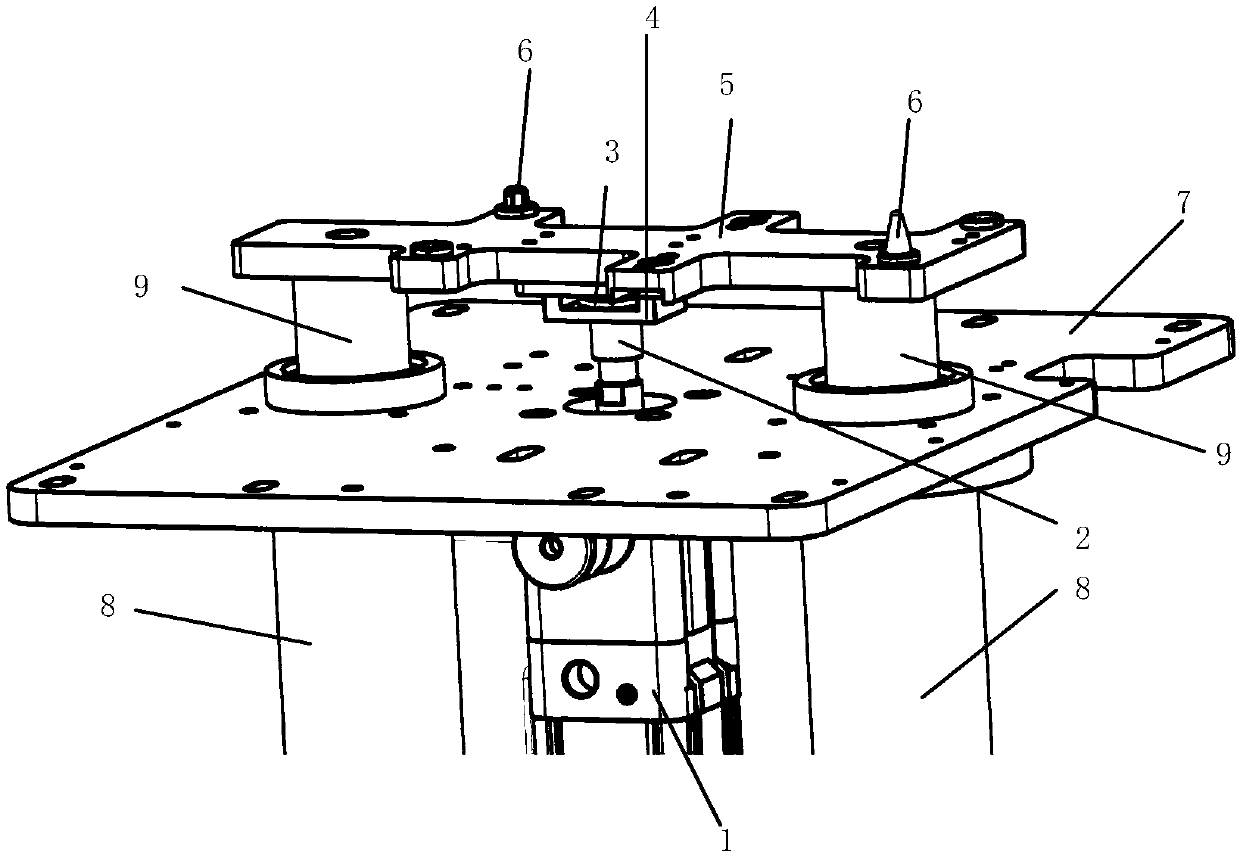

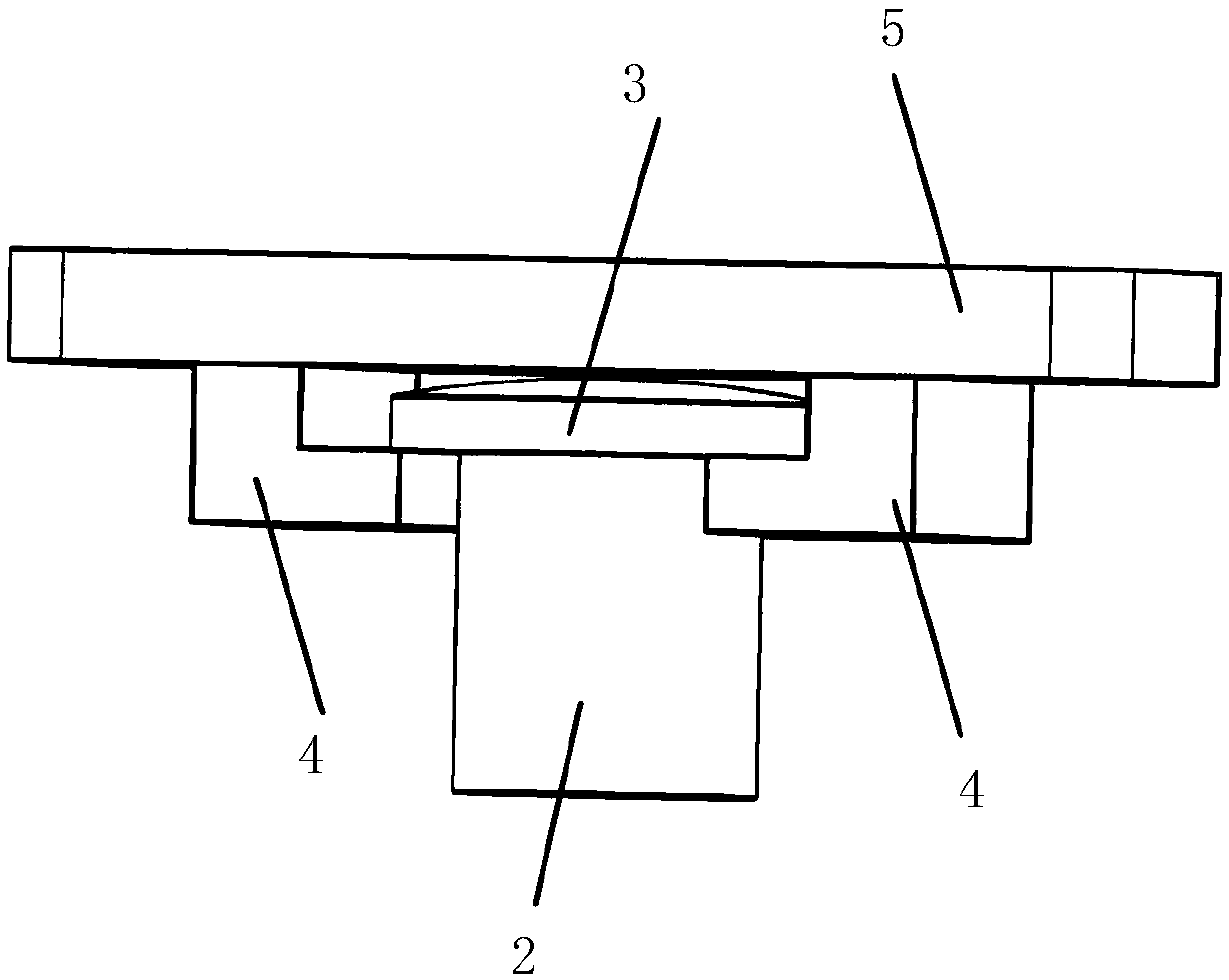

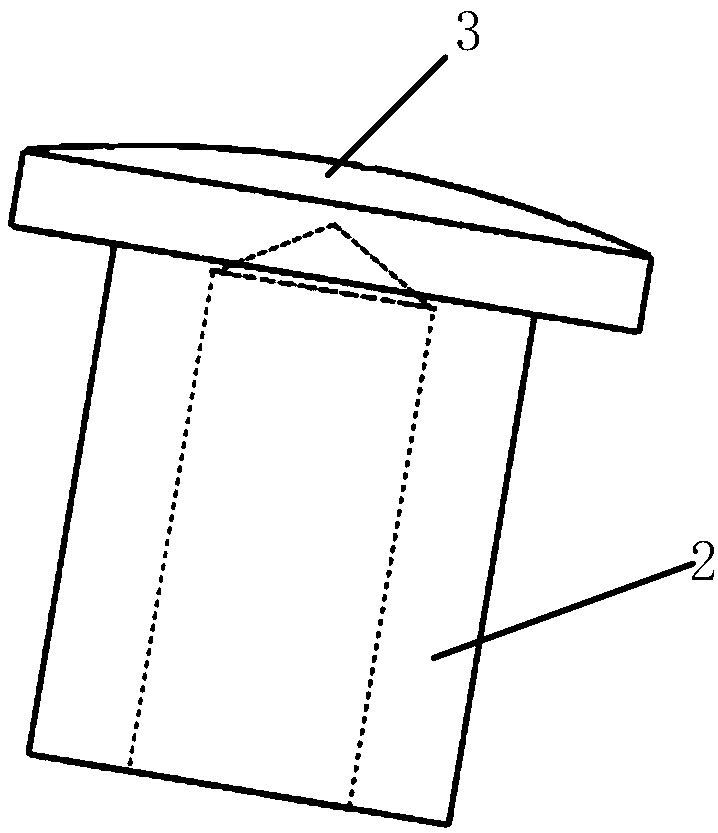

[0023] The following with attached Figure 1-3 A self-positioning tray mechanism of the present invention will be further described in detail.

[0024] A self-positioning tray mechanism of the present invention, please refer to Figure 1-3 , including a driving device, a connecting device, a tray 5 and at least two guiding devices, the connecting device is located between the driving device and the tray 5, the upper end surface of the connecting device is a spherical surface, and the upper end of the connecting device is spherical contact type Clamped on the lower part of the tray 5, the lower end of the connecting device is detachably fixed on the upper part of the driving device, the guiding device is movably connected to the left and right sides of the driving device up and down, and the upper end of the guiding device is connected to the upper part of the driving device. The lower end of the pallet 5 is fixedly connected, and the workpiece is releasably fixed on the palle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com