Hollow pile gripper and gripper system

A technology of hollow piles and grippers, applied in the direction of load hanging components, transportation and packaging, etc., to achieve the effect of restraining rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

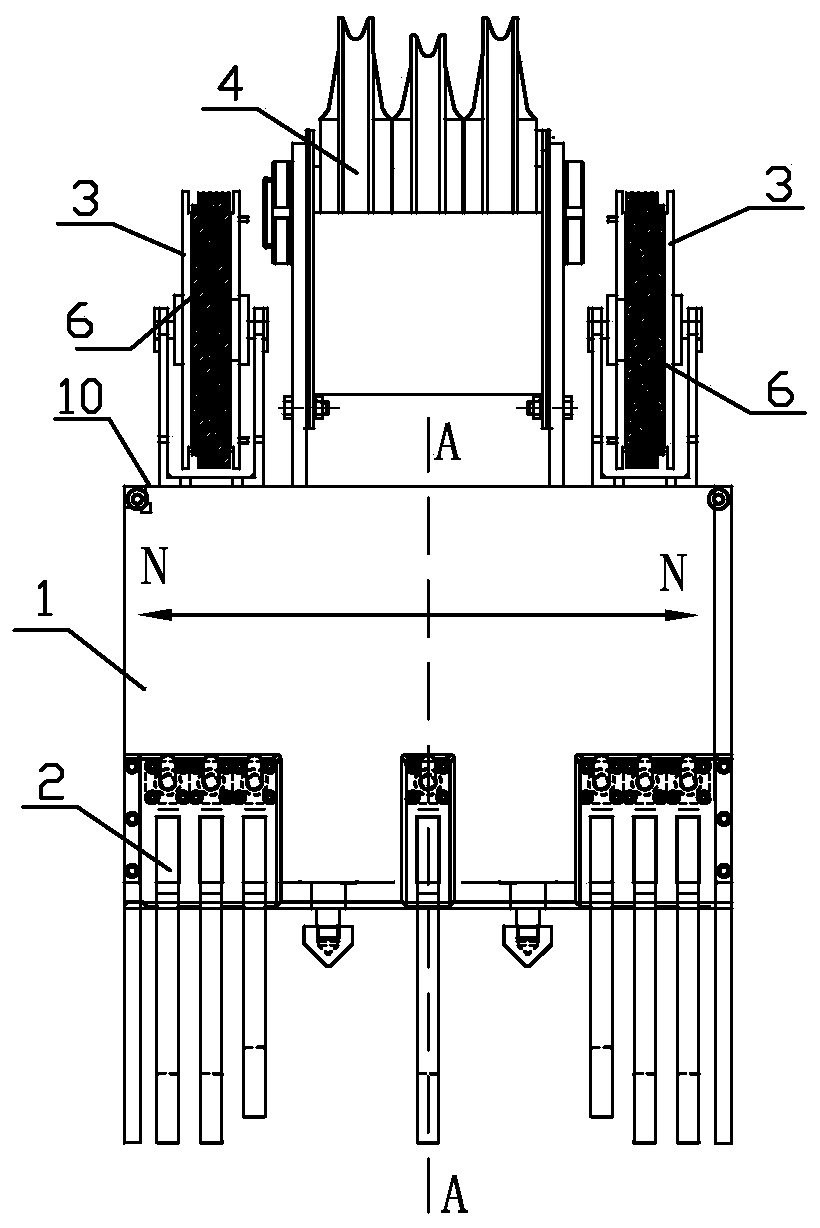

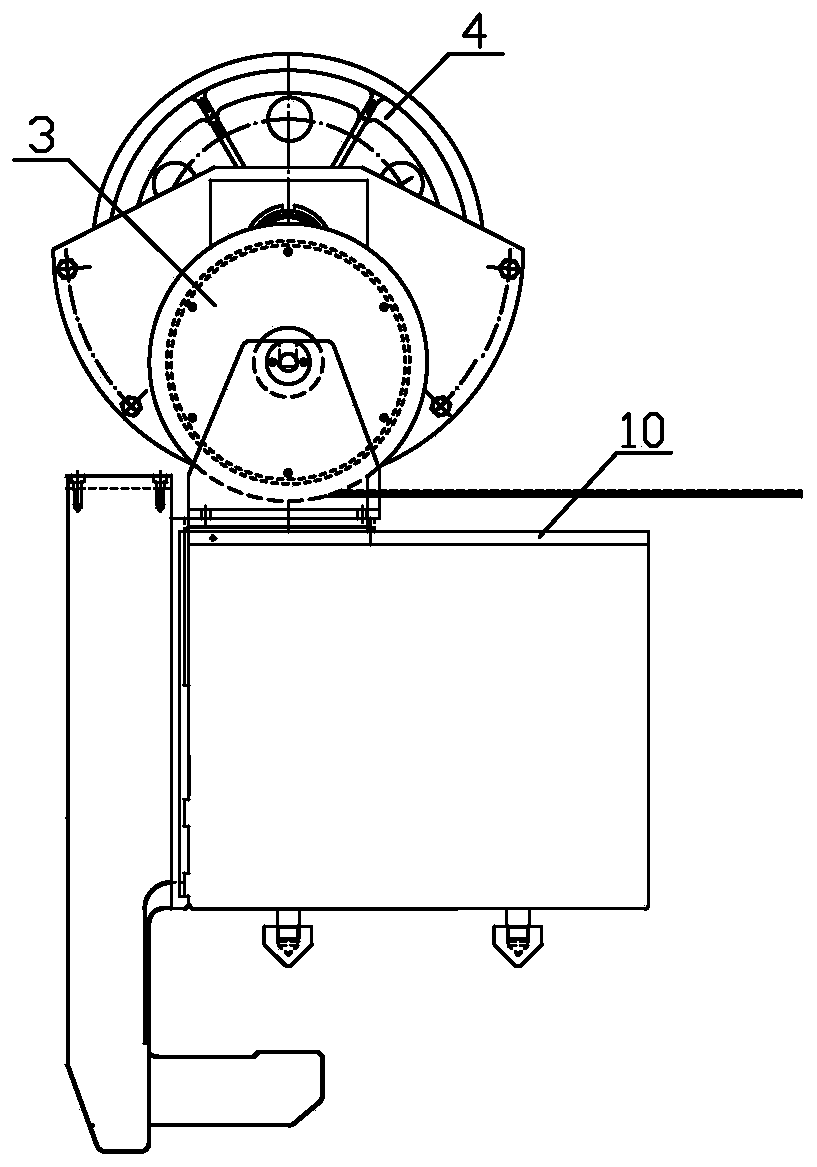

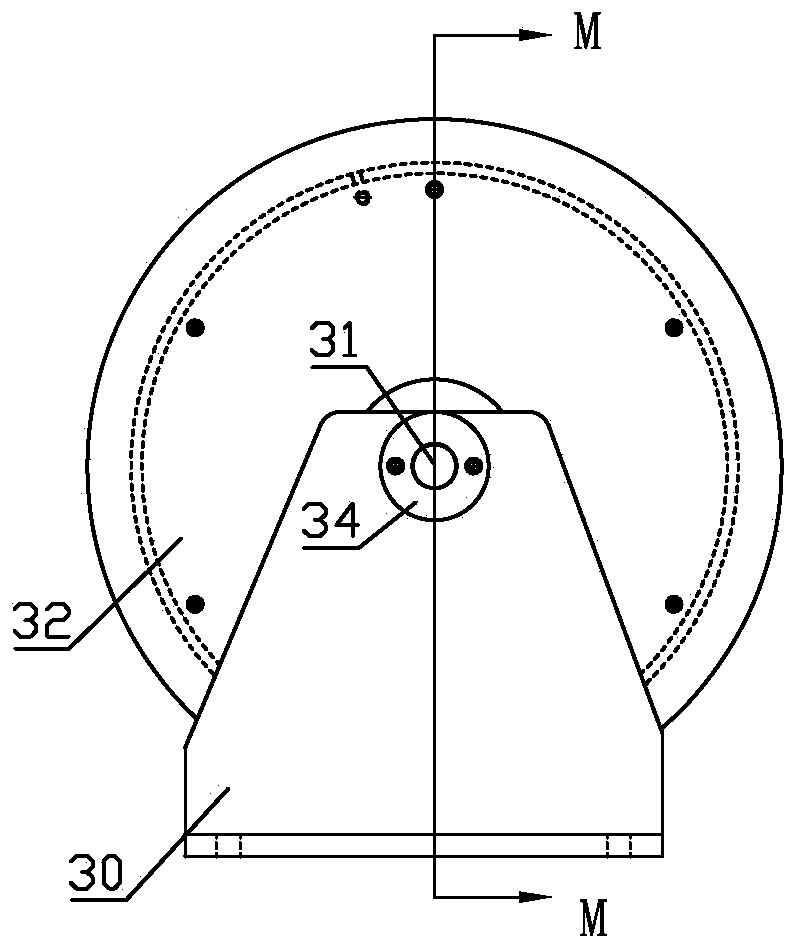

[0026] Such as figure 1 and figure 2 Shown is the hollow pile gripper disclosed by the present invention, which includes a gripper mount 1 and a hook assembly 2 arranged in the gripper mount 1, the hook assembly 2 can drive the hook to hook the hollow pile , in this embodiment, a fixed pulley block 4 is installed on the gripper mounting base 1, and the fixed pulley block 4 is connected with the crane, and the crane can drive the hollow pile gripper to move through the fixed pulley block. The hollow pile gripper disclosed by the present invention also includes a traction A rope 6 and a force applying device 3 for retracting and retracting the traction rope and exerting a certain pulling force on the traction rope during the process of retracting and retracting the traction rope;

[0027] One end of the traction rope 6 is wound on the force applying device, and the other end forms a free end;

[0028] The force applying device 3 has two groups, the force applying device 3 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com