Super-long life engine oil and preparation method thereof

A technology of ultra-long life and engine oil, which is applied in the petroleum industry, base materials, lubricating compositions, etc. It can solve the problems of increased cost of oil replacement, decreased lubrication effect, and delay in normal work, and achieves high thermal oxidation stability and longer service life. , The effect of reducing the number of oil changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

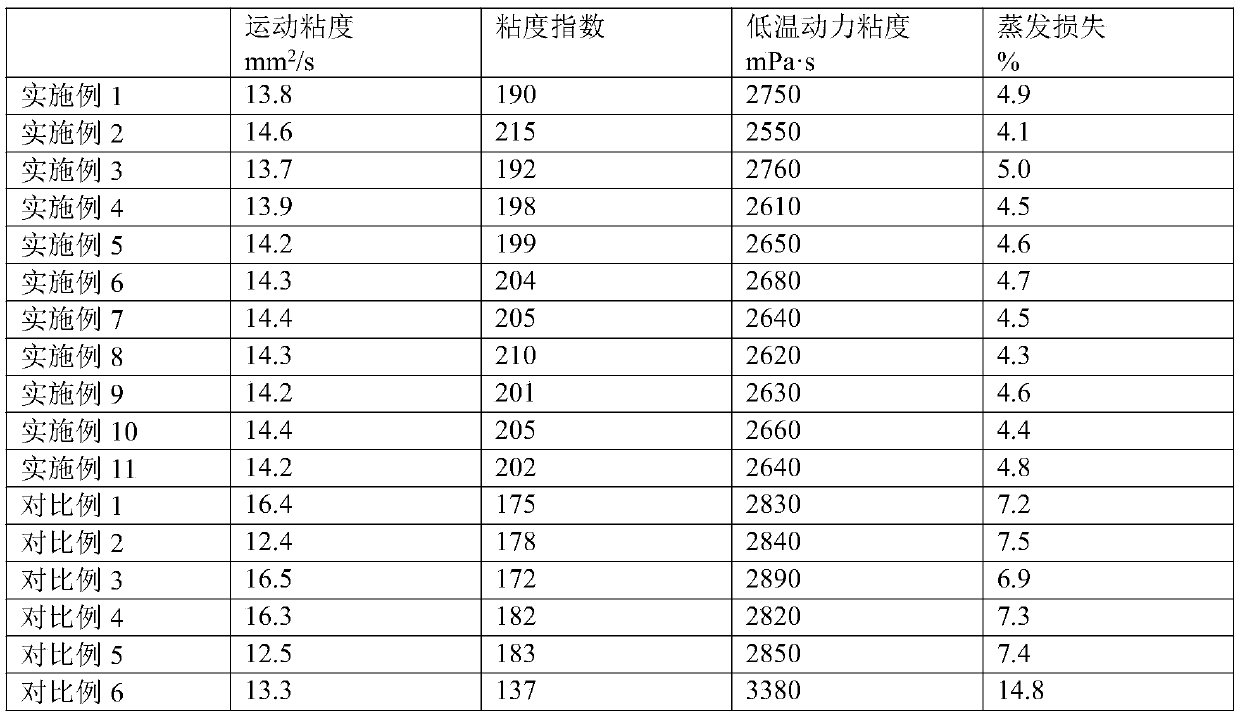

Embodiment 1

[0049] A kind of ultra-long-life machine oil, base oil and additive, by weight parts, described base oil comprises GTL base oil is 45g, alkyl naphthalene AN30 is 3g, PAO base oil is 5g, polyester is 3g, double grease is 5g; the additives include viscosity index improver 2g, pour point depressant 0.1g, multifunctional additive 15g, antiwear agent 1g. The antiwear agent includes fullerene 6316 and organic molybdenum MOLYVANR3000 with a ratio of parts by weight of 1:1; the viscosity index improver is metallocene V10100; the pour point depressant includes Vl-248 and T602 with a ratio of parts by weight of 1:1; The multifunctional additive is Afton 12210.

[0050] A preparation method of ultra-long-life machine oil, comprising the following steps:

[0051] Mix the base oil evenly, raise the temperature to 60 degrees Celsius while stirring, then add viscosity index improver and pour point depressant, stir evenly, finally add multifunctional additives and anti-wear agent, after stir...

Embodiment 2

[0053] A kind of ultra-long-life machine oil, base oil and additive, by weight parts, described base oil comprises that GTL base oil is 50g, alkyl naphthalene AN30 is 5g, PAO base oil is 8g, polyester is 5g, double grease is 6.7g; Additives include viscosity index improver 4g, pour point depressant 0.3g, multifunctional additive 18g, antiwear agent 3g. And the antiwear agent is fullerene 6316; the viscosity index improver is metallocene V10100; the pour point depressant is Vl-248; the multifunctional additive is Afton 12210.

[0054] At this time, the weight ratio of GTL base oil, PAO base oil and alkylnaphthalene AN30 is 1:0.16:0.1.

[0055] The weight ratio of PAO base oil to double fat is 1:0.84.

[0056] The weight ratio of polyester to alkylnaphthalene AN30 is 1:0.75.

[0057] A preparation method of ultra-long-life machine oil, comprising the following steps:

[0058] Mix the base oil evenly, raise the temperature to 65 degrees Celsius while stirring, then add viscosi...

Embodiment 3

[0060] A kind of ultra-long-life engine oil, comprises base oil and additive, and by weight parts, described base oil comprises GTL base oil is 55g, alkyl naphthalene AN30 is 10g, PAO base oil is 10g, polyester is 8g, double grease 10g; the additives include 6g of viscosity index improver, 0.5g of pour point depressant, 20g of multifunctional additive, and 5g of antiwear agent. The antiwear agent is fullerene 6316; the viscosity index improver is metallocene V10100; the pour point depressant includes Vl-248 and T602 with a weight ratio of 1:1; the multifunctional additive is Afton 12210.

[0061] A preparation method of ultra-long-life machine oil, comprising the following steps:

[0062] Mix base oil evenly, heat up to 70 degrees Celsius while stirring, then add viscosity index improver and pour point depressant, stir evenly, finally add multi-functional additives and anti-wear agent, after stirring evenly, settle for 9 hours to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com