Patents

Literature

37results about How to "Viscosity does not decrease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paper-plastic lamination adhesive and method for preparing same

InactiveCN1632029AImprove freeze-thaw resistanceReduce charge densitySurface covering paperEster polymer adhesivesPolymer scienceAdhesive

Disclosed are a paper-plastic glue and its preparing method,comprising of high polymer latex 70-90%,resin 5-15%,inorganic powder filler 3-15%,dispersant 0.5-0.8%,thickener 0.2-0.5% and deformer 0.1-0.3%. Its preparing method is:1.pre the deformer with high polymer latex; 2. disperse; 3. add into inorganic filler and disperse;4.add into resin and disperse;5. add into thickener for adjusting the viscosity to be the construction one,the output and package the material.

Owner:SOUTH CHINA UNIV OF TECH

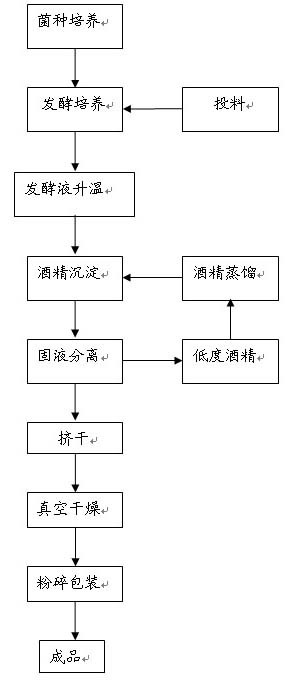

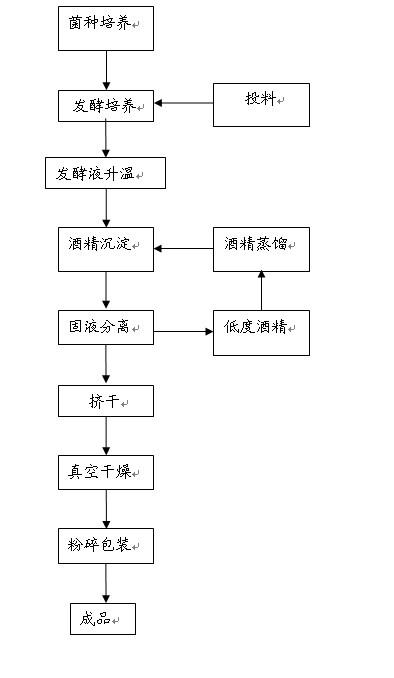

Xanthomonas, preparation method thereof and method thereof for producing temperature resistant xanthan gum polysaccharide

ActiveCN101906390AImprove temperature resistanceViscosity loss is smallBacteriaMutant preparationBiotechnologyXanthomonas campestris

The invention discloses a xanthomonas Xanthomonassp. S-96#, preparation method thereof and a method thereof for producing temperature resistant xanthan gum polysaccharide, including seed selection of temperature resistant high viscosity strain, expanding culture of seed, fermentation and extraction processing steps. The strain of the invention has good temperature resistance, the produced xanthan gum polysaccharide product has stable quality, the viscosity of the product after being heated is obviously higher than similar product, application indexes are excellent, and the original production process of similar products is improved, production process is safe, thus being capable of substituting the existing xanthan gum product and being widely applied to the petroleum development industries requiring high viscosity under high temperature condition.

Owner:ORDOS ZHONGXUAN BIOCHEM

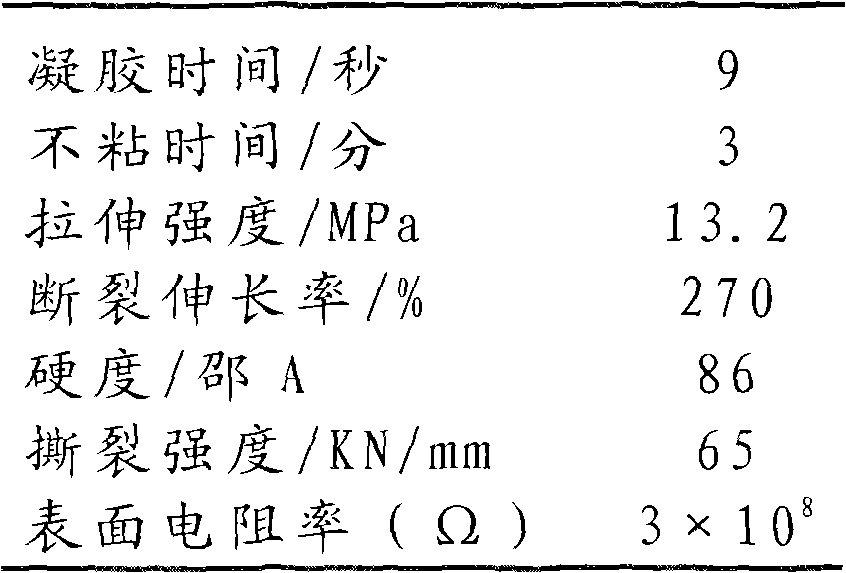

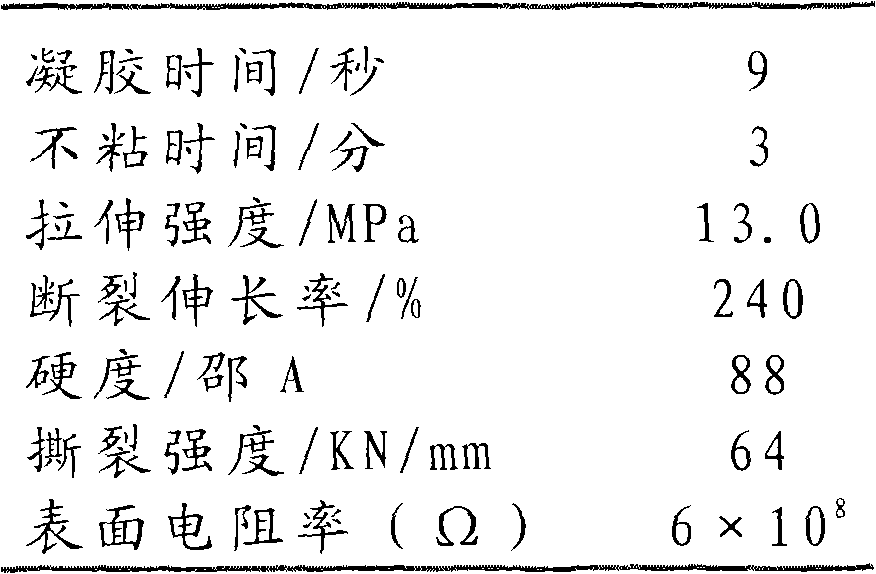

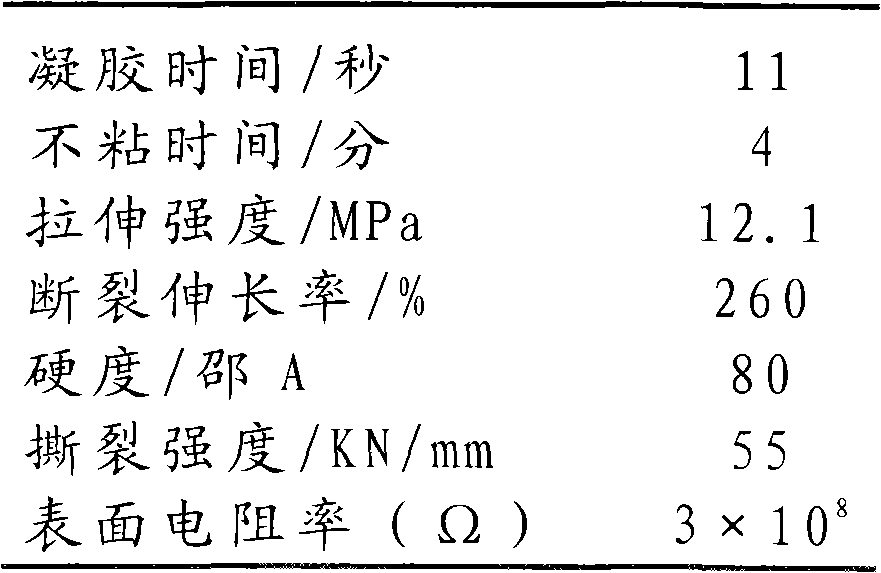

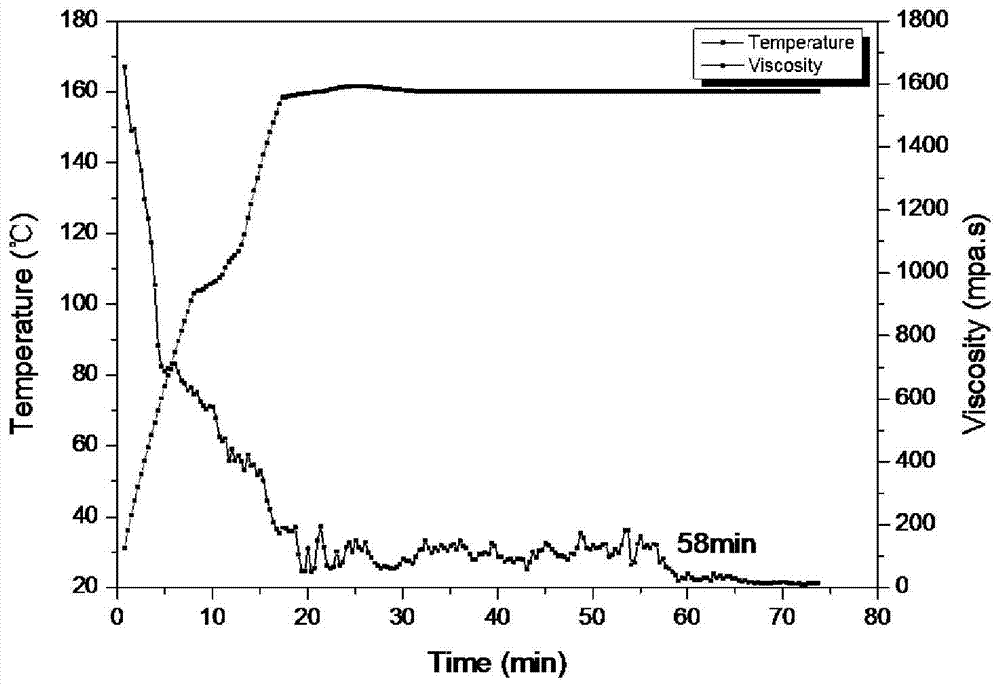

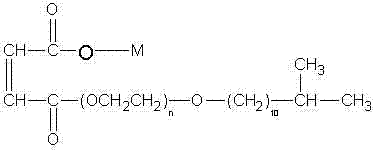

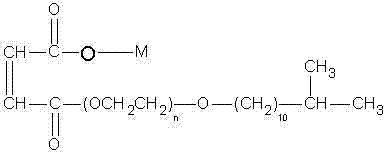

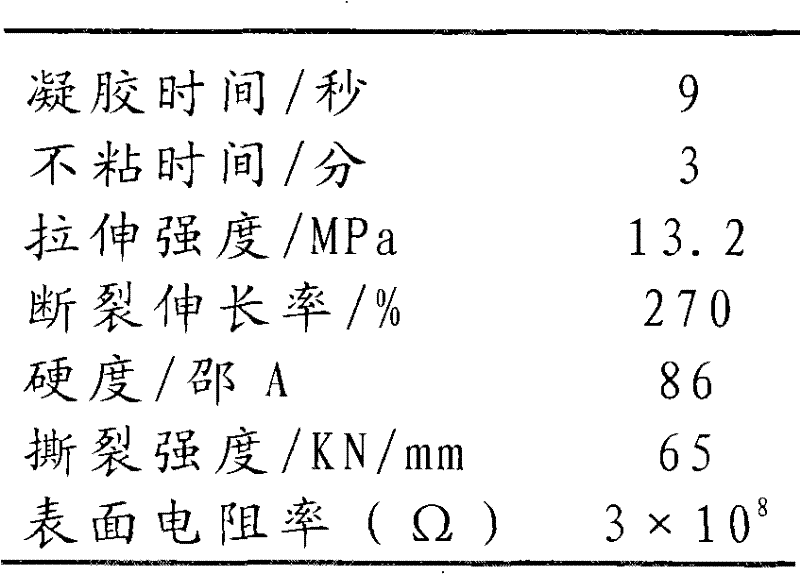

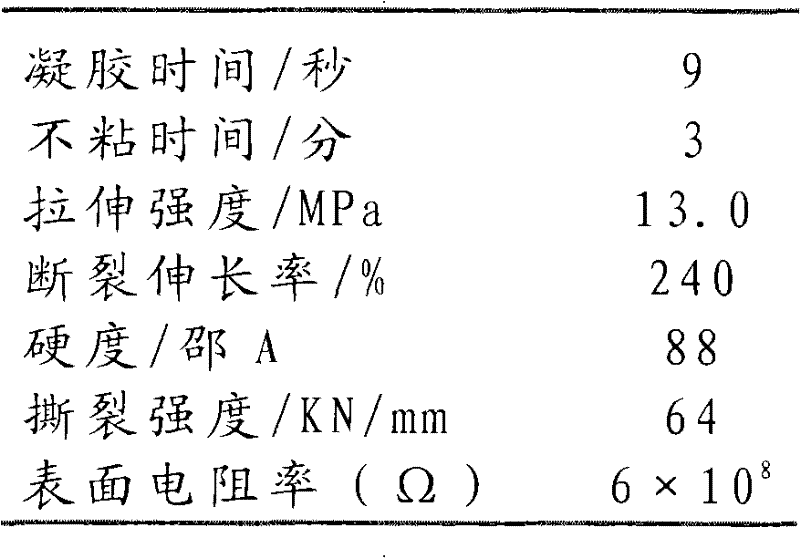

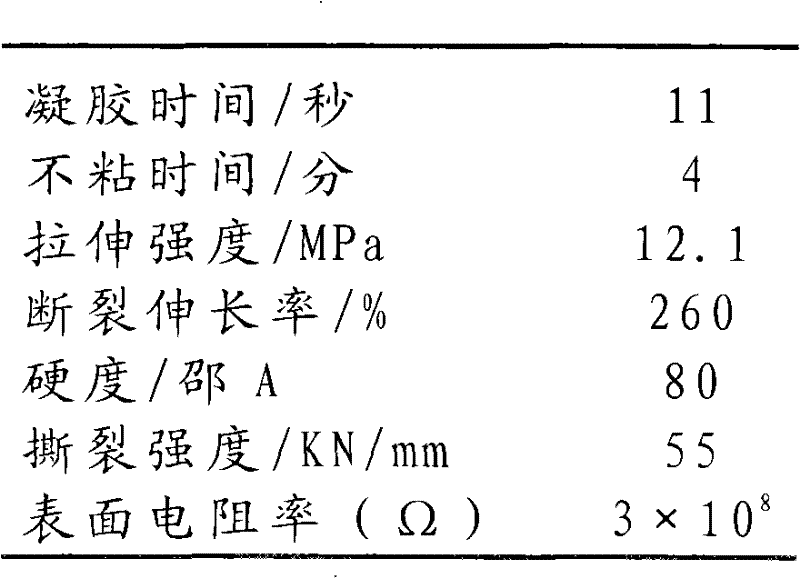

Antistatic flexible polyurea composition, preparation thereof, construction method and applications

ActiveCN101338017AGuaranteed storage stabilityLow viscosityLiquid surface applicatorsAnti-corrosive paintsElastomerAntistatic agent

The invention provides an antistatic flexible polyurea composition and a preparation method, a construction method and an application thereof, which can solve the problem existing in the prior art that the antistatic property, the miscibility and the mechanical property of the polyurea elastomer are difficult to balance thereby resulting in the limited applied range. The invention has the technical schemes that an antistatic flexible polyurea composition is characterized in that the polyurea composition is composed of a component A and a component R; the component A is quasi-prepolymer which is synthesized by 30 to 50 portions of polyisocyanate, 20 to 40 portions of polyol and 10 to 30 portions of solid antistatic agents; the component R is composed of 5 to 30 portions of amine chain extenders, 40 to 60 portions of amine terminated polyether and 10 to 30 portions of antistatic agents; the components A, R are collated to use according to 1:1 of the isocyanate index. By the invention, not only the antistatic property of the polyurea elastomer is improved, but also the miscibility as well as the mechanical performance is integrally improved.

Owner:MARINE CHEM RES INST

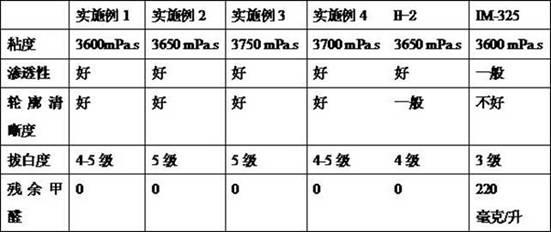

Reactive dye-white discharge printing paste and preparation method thereof

The invention relates to a reactive dye--white discharge printing paste and a preparation method thereof. The white discharge printing paste comprises the following raw materials by weight: 75 to 80 parts of acrylic acid, 9 to 11 parts of acrylamide, 57 to 62 parts of methacrylic acid, 78 to 82 parts of 2-acrylamide-2-methylacrylsulfonate, 360 to 380 parts of 20 % ammonia, 3.5 to 4.0 parts of ammonium persulfate, 1.9 to 2.6 parts of sodium bisulfite, and 490 to 520 parts of water. The method comprises the following steps: polymerizing all the liquors, adding 114 to 118 parts of starch to the copolymer, pasting, and filtering. As thiourea dioxide is taken as a white discharge agent, a fabric is easy to wash with water after print discharging; and no methanal is left on the fabric, so as tobe more environment-friendly.

Owner:LIAONING FIXED STAR FINE CHEM

Low-alcohol concentration wet processing method for refined konjak powder

ActiveCN103461902AReduce processing costsPrevent excessive swellingFood preparationFood processingAlcohol

The invention discloses a low-alcohol concentration wet processing method for refined konjak powder. The method can effectively reduce processing cost. The method comprises the following steps: A, cleaning and peeling konjak; B, cutting the konjak and protecting the color of the konjak; C, crushing, grinding and separating the konjak at a temperature of -10 to 0 DEG C, i.e., mixing the konjak with alcohol with a concentration of 5 to 15%, then crushing an obtained mixture to obtain pulp, subjecting the pulp to solid-liquid separation to obtain konjak powder, mixing the konjak powder with alcohol with a concentration of 5 to 15%, carrying out grinding to obtain a solid-liquid mixture and subjecting the solid-liquid mixture to centrifugation so as to obtain the refined konjak powder; and D, drying the refined konjak powder. According to the method, crushing, grinding and separation of the konjak are carried out at a temperature of -10 to 0 DEG C, so usage of alcohol with a concentration of only 5 to 15% is capable of preventing refined powder particles from excess swelling or formation of sol, thereby substantially reducing cost. The method is suitable for being popularized and applied in the field of food processing.

Owner:南京喜之郎食品有限公司

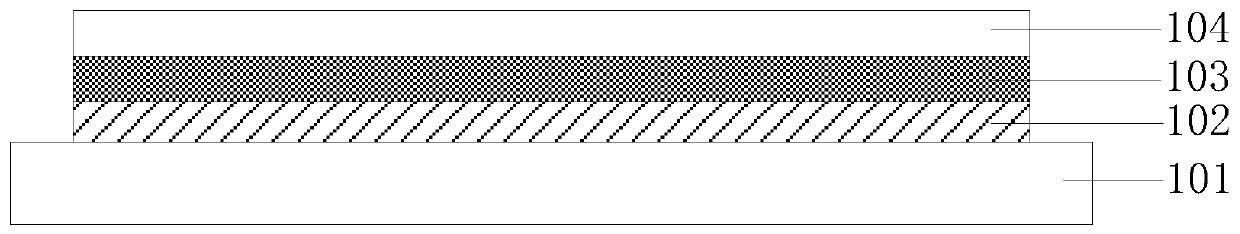

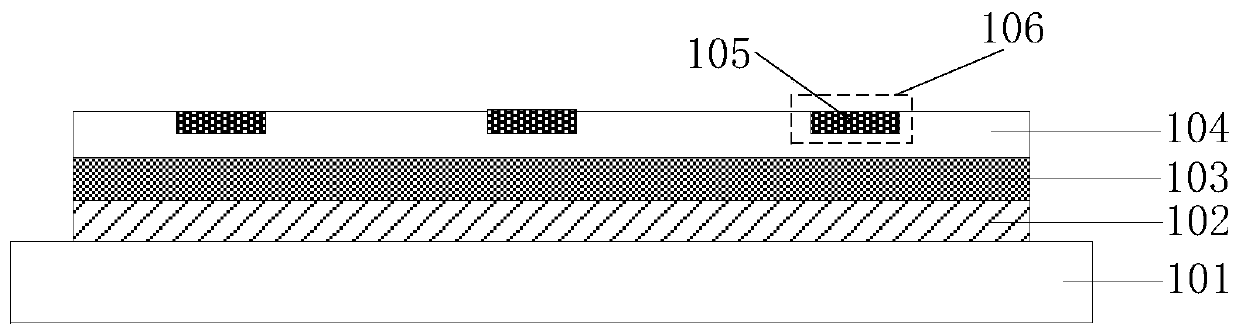

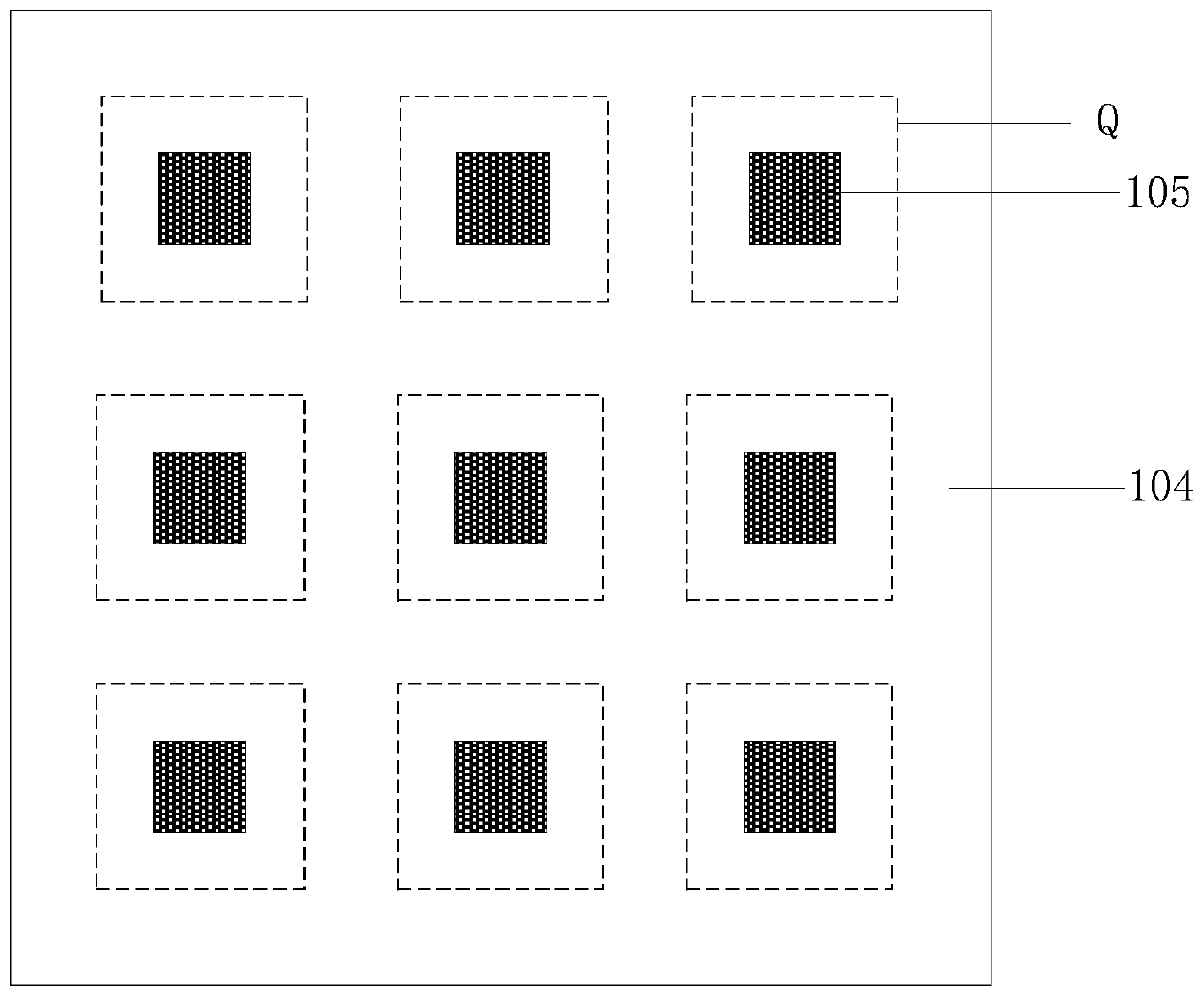

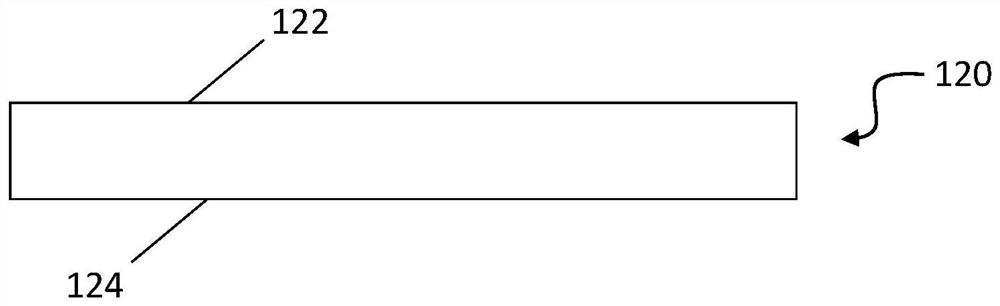

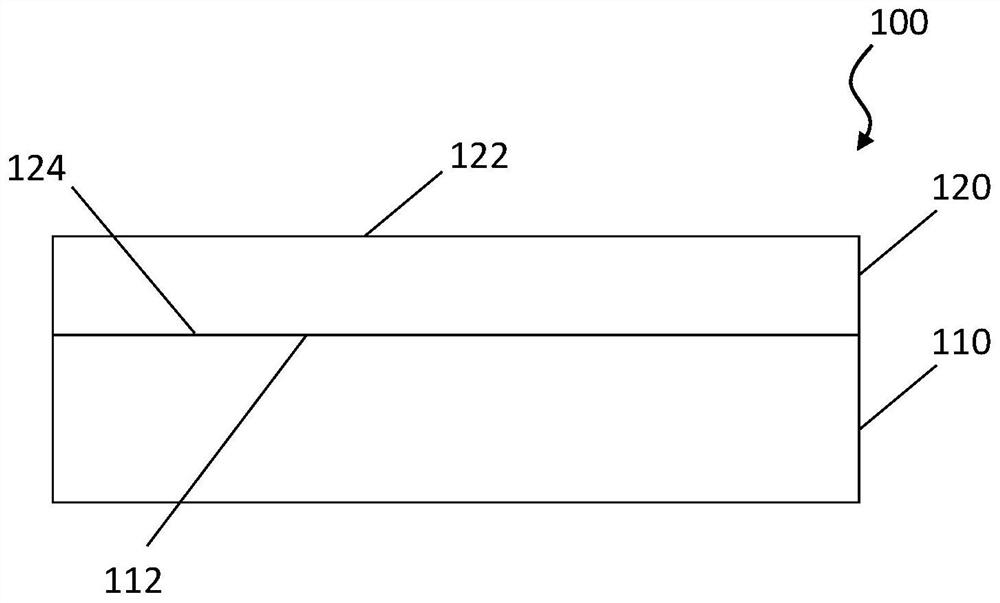

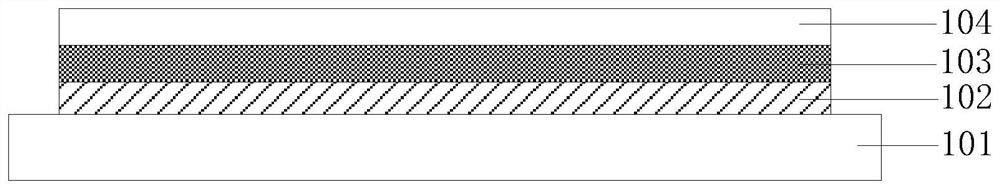

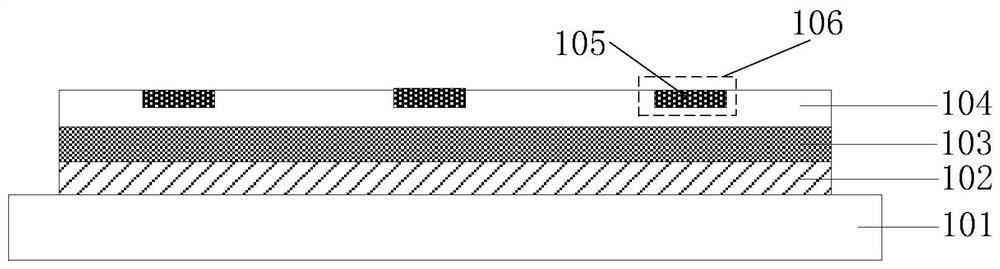

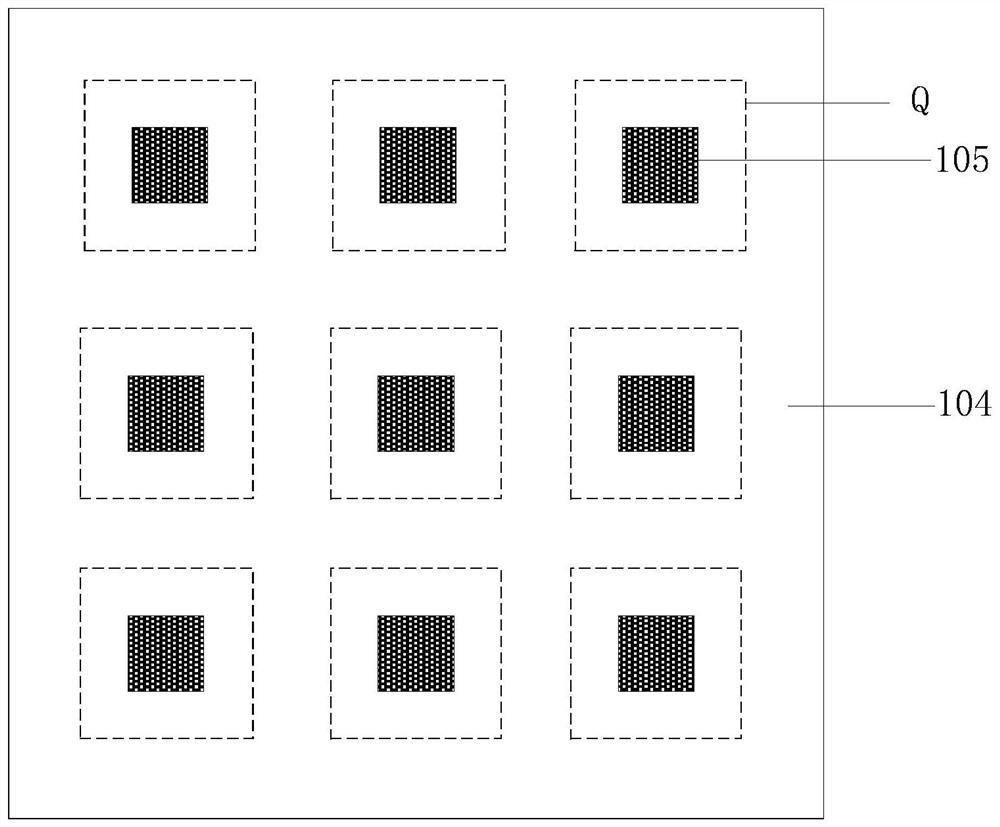

Transfer substrate, transfer method of light-emitting diode and transfer equipment

ActiveCN110265348ALow viscosityReduce viscositySemiconductor/solid-state device testing/measurementSolid-state devicesWavelength rangeLight source

The invention discloses a transfer substrate, a transfer method of a light-emitting diode and transfer equipment. The transfer substrate comprises a substrate, a reflecting layer, an optical conversion layer and a light-sensitive visbreaking film, wherein the reflecting layer is arranged at one side of the substrate, the optical conversion layer is arranged at one side, deviating from the substrate, of the reflecting layer, the light-sensitive visbreaking film is arranged at one side, deviating from the reflecting layer, of the optical conversion layer, the optical conversion layer is used for converting a light ray within a certain wavelength range to non-visible light, the light-sensitive visbreaking film is used for pasting the light-emitting diode, and the viscosity is reduced to relieve the light-emitting diode after irradiation of the non-visible light. By the transfer substrate, the transferring and the detection of the light-emitting diode can be simultaneously completed, the light-emitting diode with abnormal in light emitting is found out and transferred before a binding process, the problems that the light-emitting diode with abnormal light emitting is difficult to take out and the array substrate is damaged by a laser cutting process are prevented, the transfer process flow is simplified, and the transfer yield and efficiency is improved; and moreover, a light source of the non-visible light is not needed to be additionally arranged, and the transfer substrate is simple in structure and relatively low in detection cost.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Water-based paint with high weatherability

InactiveCN104059440AImproves UV resistanceImprove liquidityPolyurea/polyurethane coatingsWater basedEmulsion

The invention relates to a water-based paint with high weatherability. The paint comprises the following raw materials by weight: 40-60 parts of a mixture of polyurethane resin and polystyrene-acrylate copolymer emulsion, 15-25 parts of kaolin, 0.5-3 parts of an iron series pigment, 0.1-0.8 part of borax, 0.5-2 parts of an anti-aging agent, 0.5-2 parts of antioxidant 3010, 0.5-3 parts of a defoaming agent HT6520, 0.1-3 parts of a dispersant, 0.1-1 part of an emulsifier, 0.1-1 part of ammonia, 5- 8 parts of PTFE and 25-50 parts of water; and the anti-aging agent is a mixture of a UV absorber UVP-327 and a light stabilizer 744 in a mixing proportion of 1-2:1. The invention mainly solves the technical problems of weak dispersion and weatherability of water-based paint in the prior art.

Owner:BLUESTAR CHENGDU NEW MATERIALS

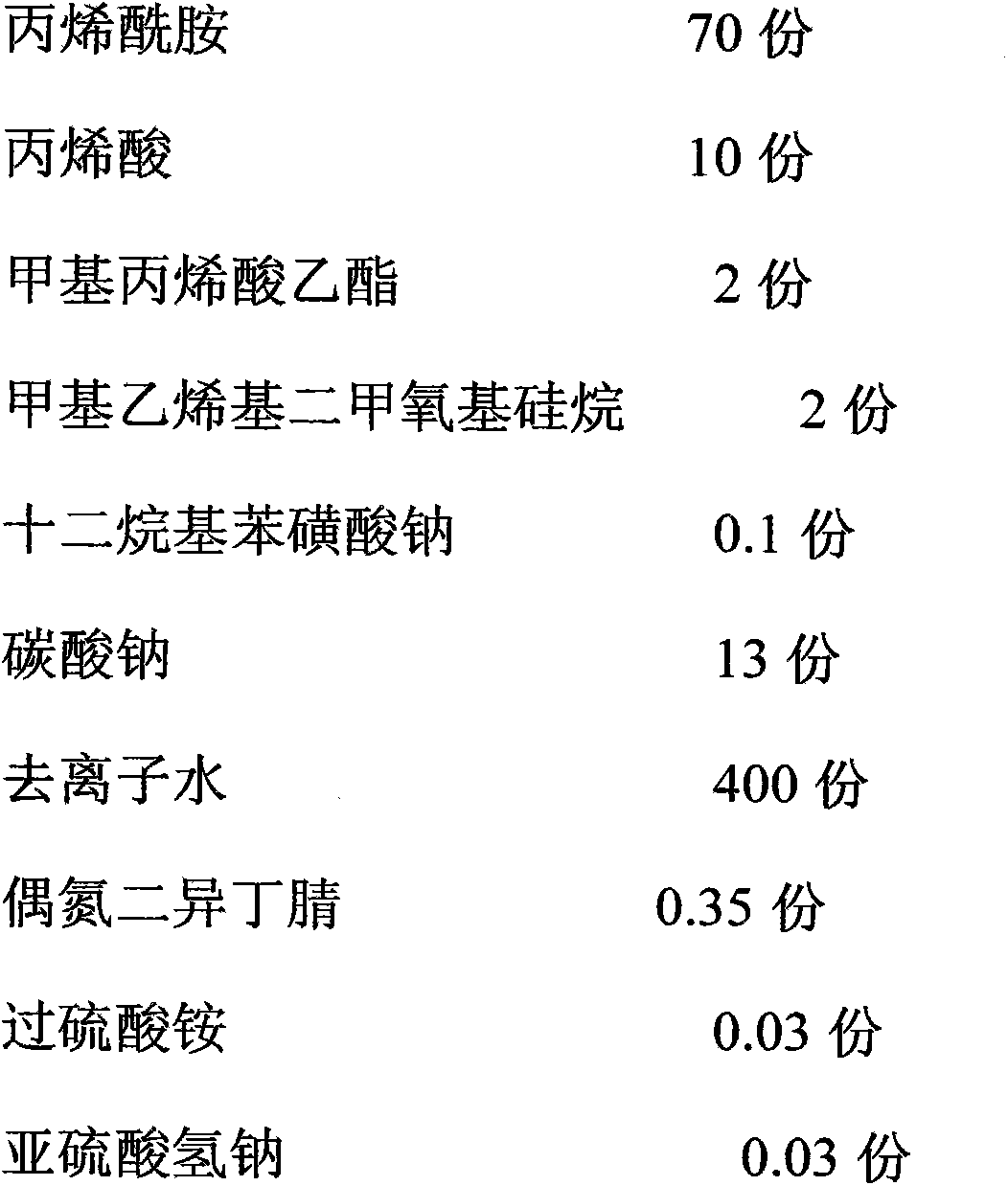

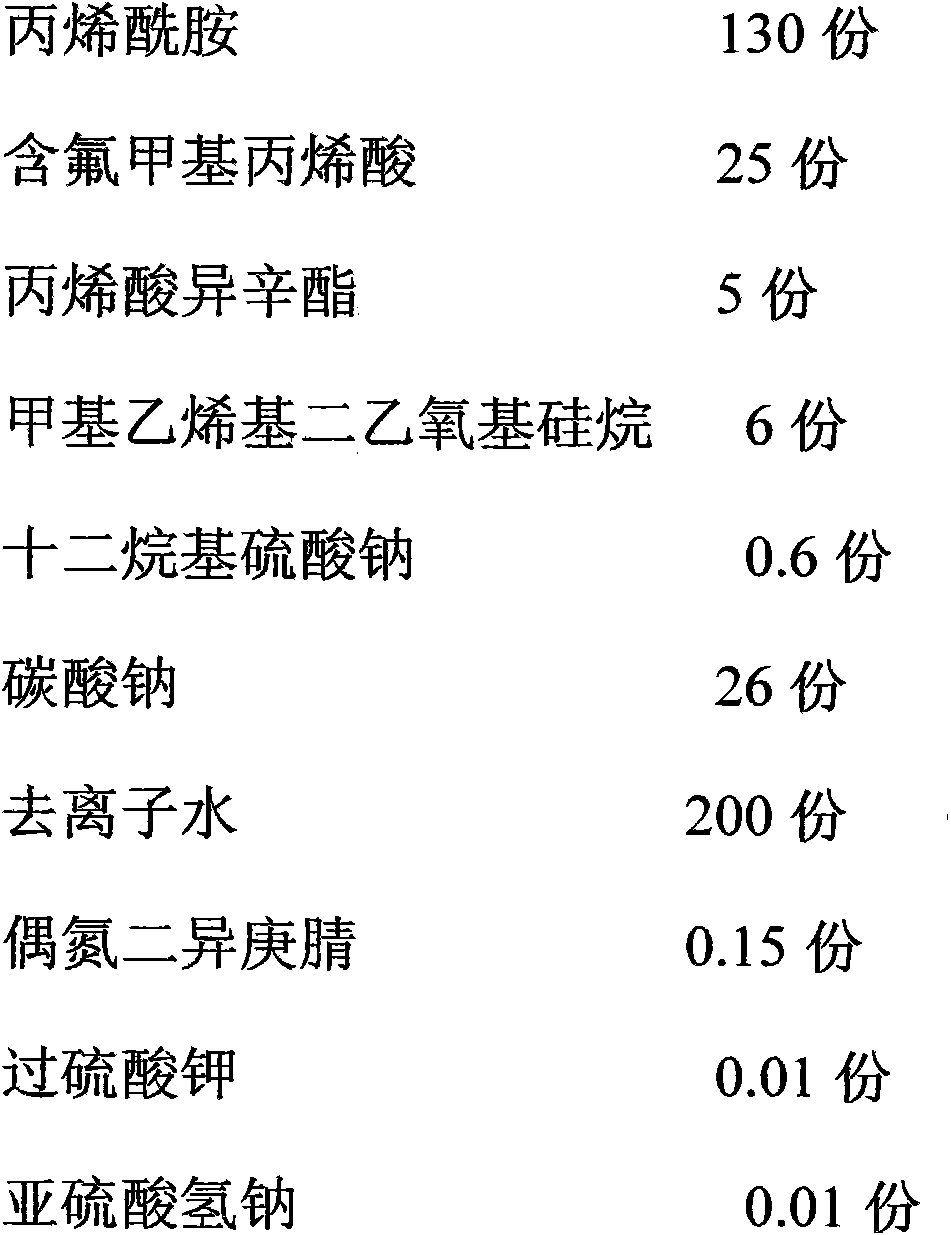

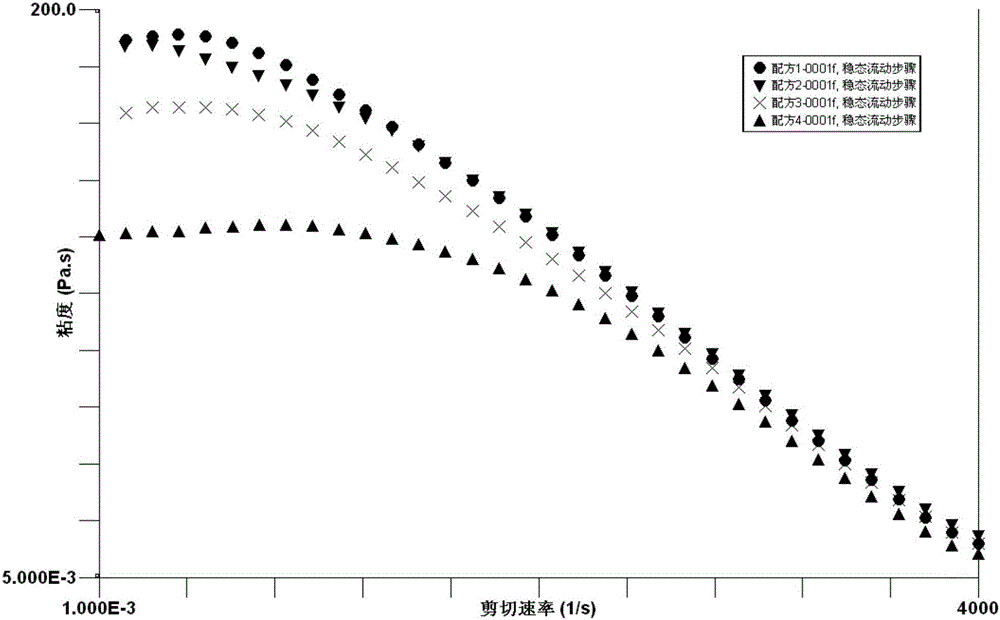

Alkali-resisting polymer for displacement of reservoir oil of oil field and preparation method thereof

InactiveCN104311735AIncrease the relative molecular massMany linksDrilling compositionNitrogenOil field

The invention discloses an alkali-resisting polymer for displacement of reservoir oil of an oil field and a preparation method thereof. The alkali-resisting polymer is prepared from the following components in parts by weight: 70-130 parts of acrylamide, 10-25 parts of a negative ion monomer, 2-5 parts of a hydrophobic monomer, 2-6 parts of an alkali-resisting monomer, 0.1-0.6% of a surfactant, 13-26 parts of sodium carbonate and 200-400 parts of deionized water. The preparation method disclosed by the invention comprises the following steps: preparing an aqueous solution by acrylamide; adding sodium carbonate, negative ion monomer, hydrophobic monomer, alkali-resisting monomer and surfactant; transferring into a reactor; introducing nitrogen for 30 minutes; adding a 1# initiator; continuously introducing nitrogen for 10 minutes; adding a 2# initiator; introducing nitrogen for 10 minutes and adding a 3# initiator; continuously introducing nitrogen till the temperature is raised to 1-2 DEG C; stopping introduction of nitrogen; raising the temperature to peak temperature and insulating for 6 hours; and cutting, granulating, drying and crushing. By adding the alkali-resisting monomer into the alkali-resisting polymer disclosed by the invention, the viscosity of the product is not reduced in a ternary system. The viscosity retention rate for 90 days is over 80%.

Owner:黑龙江吉地油田服务股份有限公司

Lubricant

The invention relates to a lubricant, aiming at providing the lubricant which is used for protecting mucosa such as rectum, oral cavity and the like, in particular to cavitary internal mucosa, and simultaneously causes the lubrication to become good. The lubricant is a solution comprising polyacrylate sodium and is prepared by the step that the polyacrylate sodium with more than 10000 average degree of polymerization of viscosity is dissolved by water or water solubility. The water or water-solubility solvent and the polyacrylate sodium have the following mass ratio relationship: the water or water-solubility solvent is 91-99 mass percent, the polyacrylate sodium is 9-1 mass percent, the viscosity of the solution is 3000-30000cps in 36 DEG C, and the pH value of the solution is adjusted to range from 3.5-10.5 by adding polymer acid. When in use, the product does not bring displeasure caused by membrane feel and incitation, and can be easily cleaned with water after being used, thereby the lubricant has good use feeling.

Owner:中岛俊之

Viscosity-stable eye drops containing polyalcohol-inorganic salt-xanthan gum ternary system and preparation method thereof

InactiveCN106137954AImprove bioavailabilityIncrease ionic strengthAntibacterial agentsOrganic active ingredientsOcular inflammationDegradation Problem

The invention belongs to the technical field of medicine, and relates to an eye drop with stable viscosity comprising polyol-inorganic salt-xanthan gum ternary system and a preparation method thereof, comprising: moxifloxacin hydrochloride 0.5-0.6% w / v; xanthan glue 0.5-0.8% w / v; polyol compound 0.1-1% w / v; For the degradation problem of raw gum after sterilization, increase the ionic strength and add soluble alcohols as antioxidants to form a polyol-inorganic salt-xanthan gum ternary system, so that the viscosity does not decrease after sterilization and ensure that the eye drops are in the eyes The static viscosity of the part is 40-80pa s; it provides improved bioavailability for eye drops, which can more effectively treat ocular inflammation, and the contact angle of this product is small, which can increase the wetting effect of ocular tissue , There is no feeling of stickiness, which greatly improves the patient's compliance.

Owner:SHANGHAI HAOHAI BIOLOGICAL TECH

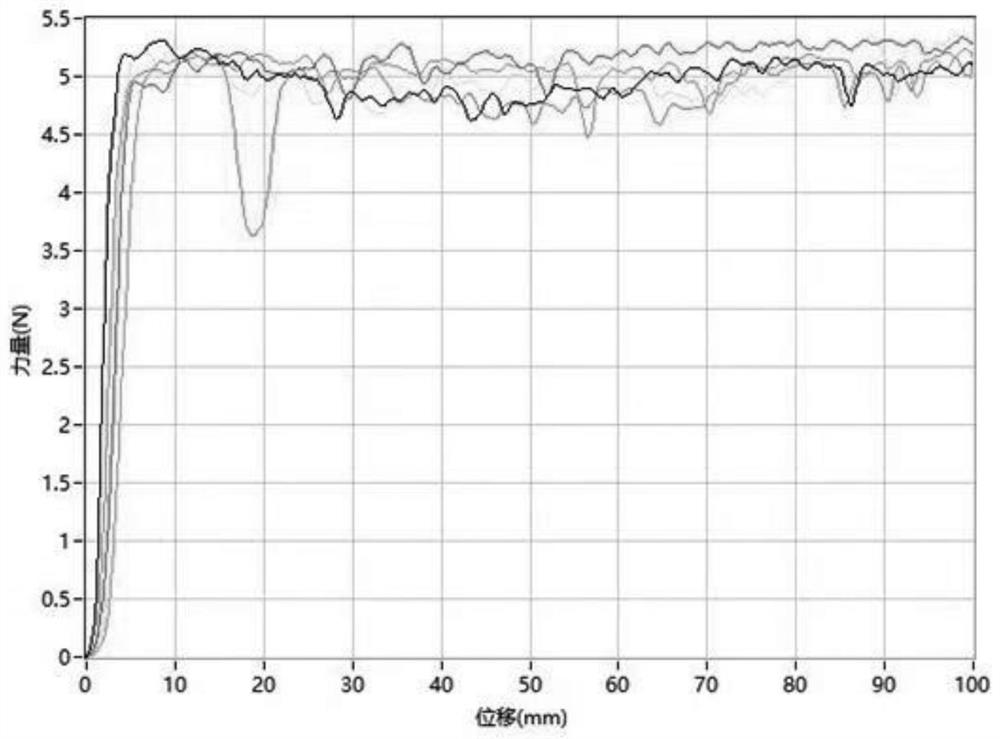

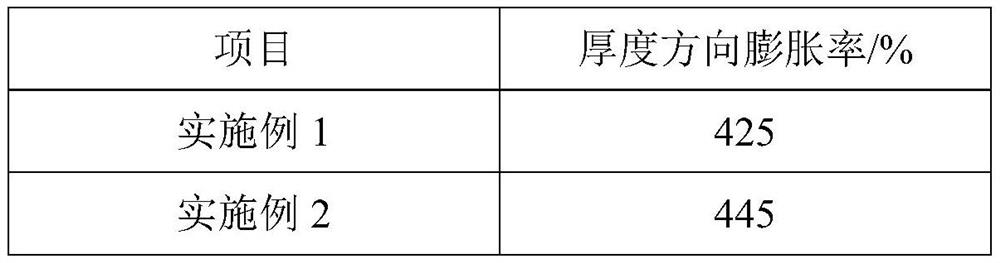

High-temperature-resistant and easy-to-unroll composite expansion adhesive tape, and preparation method and application thereof

PendingCN113956816AAchieve modificationImprove phase structureCell component detailsFilm/foil adhesive release linersPolymer scienceAdhesive

The invention provides a high-temperature-resistant and easy-to-unroll composite expansion adhesive tape. The composite expansion adhesive tape comprises a base layer and an adhesive layer which are compounded with each other, and the adhesive layer comprises a temperature-resistant layer; and the base layer is an oriented polystyrene film, and the oriented polystyrene film is prepared from, by weight, 85-90% of general polystyrene, 5-8% of high-impact polystyrene and 0.9-2.3% of nano silicon dioxide. The composite expansion adhesive tape provided by the invention has high expansion rate, can be kept not shrunk at high temperature, and is easy to uncoil in industrial production.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

Seaweed original pulp nutritive sausage and preparation method thereof

InactiveCN108576698AHigh in nutrientsUnique flavorLipidic food ingredientsFood ingredient functionsNutrientFlavor

The invention relates to a seaweed original pulp nutritive sausage and a preparation method thereof. The seaweed original pulp nutritive sausage contains seaweed original pulp and is characterized inthat in the preparation process of the seaweed original pulp, seaweed is rubbed and cleaned with salt water. The seaweed original pulp is high in content of nutrient substances, unique in flavor, tender and crisp in mouth feel and easy to store.

Owner:招远昊宇新材料有限责任公司

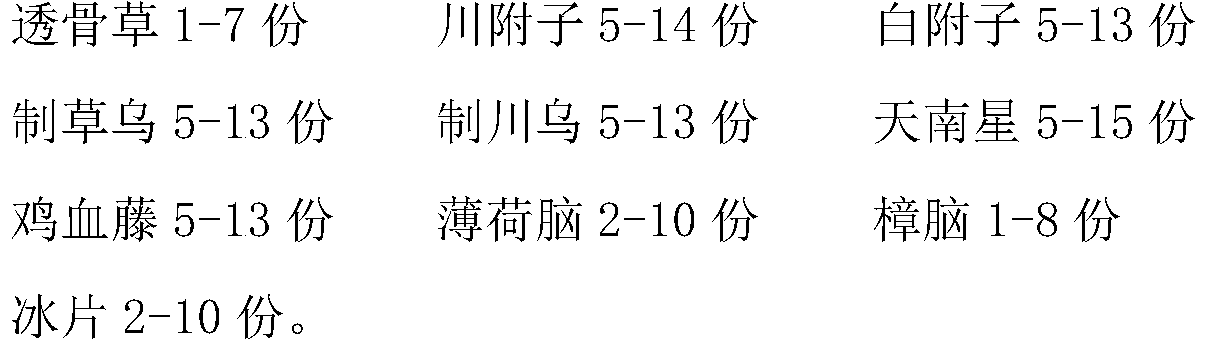

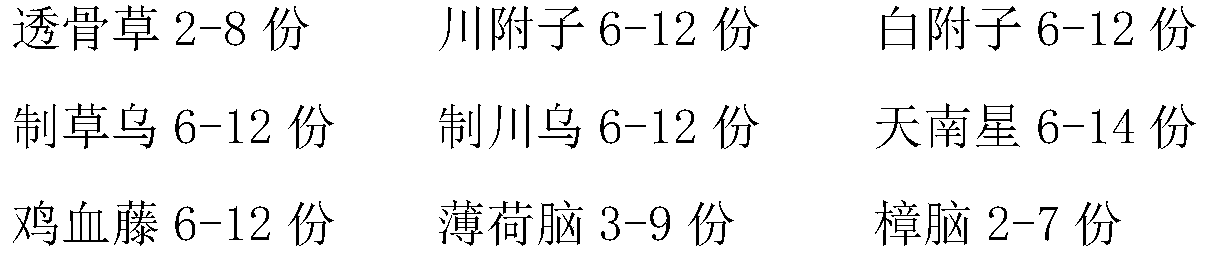

Non-allergic rubber plaster and preparation method thereof

ActiveCN109908112AImprove transdermal absorption rateViscosity will not decrease after repeated useHydroxy compound active ingredientsOil/fats/waxes non-active ingredientsRadix AconitiMint family

The invention provides a non-allergic rubber plaster and a preparation method thereof, and belongs to the technical field of plaster preparations. The rubber plaster comprises the following medicinalmaterials in parts by weight: 1-7 parts of herba speranskiae tuberculatae, 5-14 parts of radix aconiti lateralis preparata, 5-13 parts of rhizoma typhonii, 5-13 parts of radix aconiti agrestis praeparata, 5-13 parts of radix aconiti sinensis praeparata, 5-15 parts of rhizoma arisaematis, 5-13 parts of caulis spatholobi, 2-10 parts of mentha canadaensis l., 1-8 parts of camphora and 2-10 parts of borneolum syntheticum. The non-allergic rubber plaster uses high molecular artificial rubber instead of natural rubber, and thus the allergy problem is effectively solved; by controlling the types andcontents of main drug components in the plaster and improving auxiliary material components, the prepared rubber plaster has higher transdermal absorption rate, can rapidly absorb the effective drug components, improves the treatment effect, and meanwhile, the plaster has higher adhesive performance and higher stability.

Owner:INNER MONGOLIA HORQIN PHARMA CO LTD

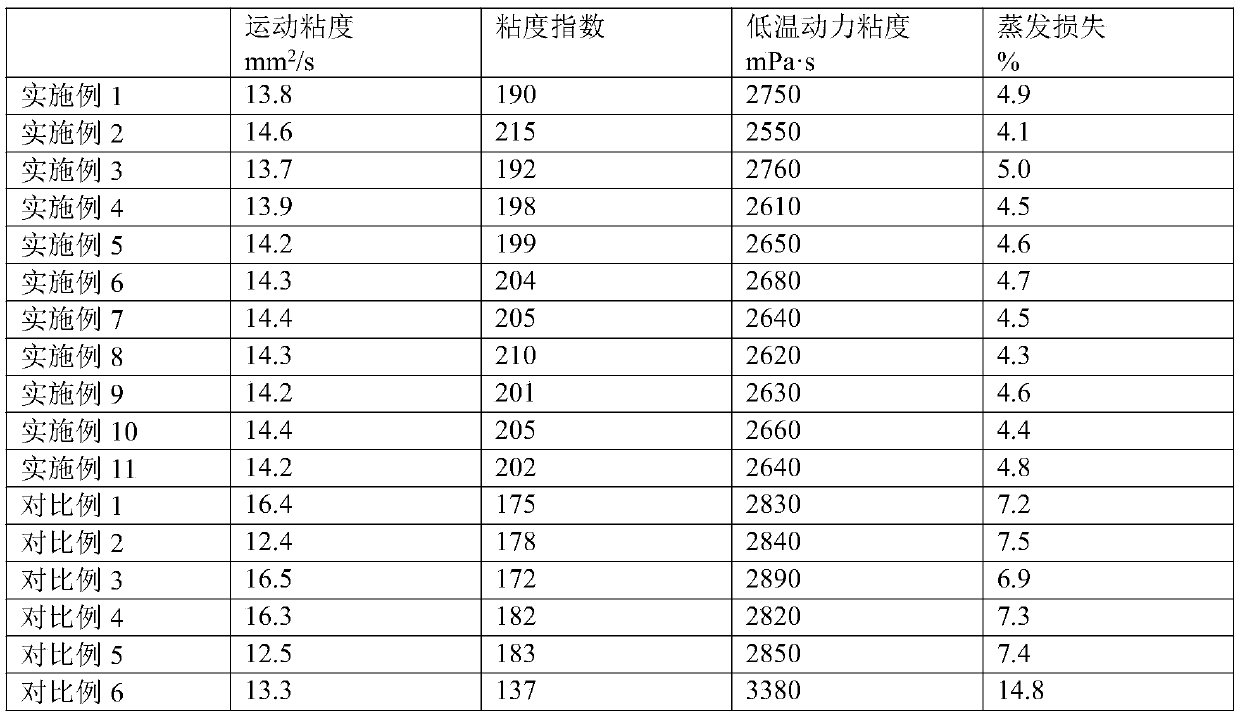

Super-long life engine oil and preparation method thereof

The invention relates to super-long life engine oil, and belongs to the technical field of engine oil. The engine oil comprises base oil and an additive. The base oil comprises following components inparts by weight: 45-55 parts of GTL base oil, 3-10 parts of alkyl naphthalene AN30, 5-10 parts of PAO base oil, 3-8 parts of polyester, and 5-10 parts of diester; and the additive comprises followingcomponents in parts by weight: 2-6 parts of a viscosity index improver; 0.1 to 0.5 part of a pour point depressant; 15 to 20 parts of a multifunctional additive; and 1 to 5 parts of an anti-wear agent. The preparation method comprises the following steps: uniformly mixing the base oil, heating to a temperature of 60-70 DEG C under stirring; adding a viscosity index improver and a pour point depressant, uniformly stirring, finally adding a multifunctional additive and an anti-wear agent, uniformly stirring, and standing for 7-9 hours to obtain a finished product. The engine oil has the advantages of long service life and reduction of oil change frequency.

Owner:河北冠元润滑科技有限公司

A water-based coating with high weather resistance

InactiveCN104059440BImproves UV resistanceImprove liquidityPolyurea/polyurethane coatingsWater basedPolystyrene

The invention relates to a water-based paint with high weatherability. The paint comprises the following raw materials by weight: 40-60 parts of a mixture of polyurethane resin and polystyrene-acrylate copolymer emulsion, 15-25 parts of kaolin, 0.5-3 parts of an iron series pigment, 0.1-0.8 part of borax, 0.5-2 parts of an anti-aging agent, 0.5-2 parts of antioxidant 3010, 0.5-3 parts of a defoaming agent HT6520, 0.1-3 parts of a dispersant, 0.1-1 part of an emulsifier, 0.1-1 part of ammonia, 5- 8 parts of PTFE and 25-50 parts of water; and the anti-aging agent is a mixture of a UV absorber UVP-327 and a light stabilizer 744 in a mixing proportion of 1-2:1. The invention mainly solves the technical problems of weak dispersion and weatherability of water-based paint in the prior art.

Owner:BLUESTAR CHENGDU NEW MATERIALS

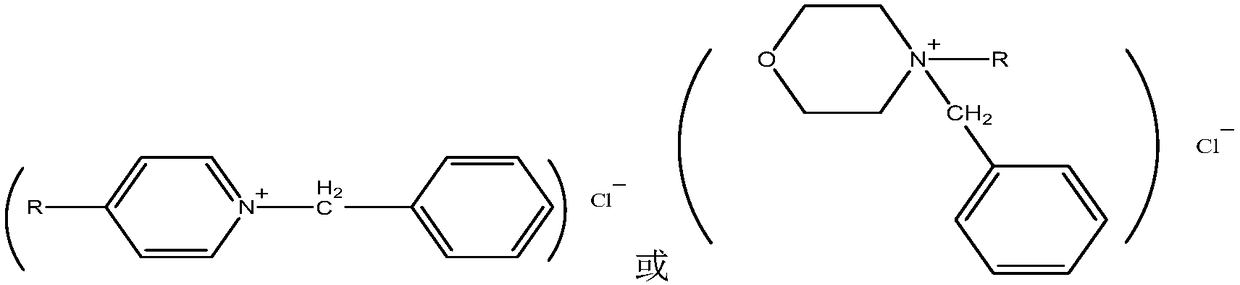

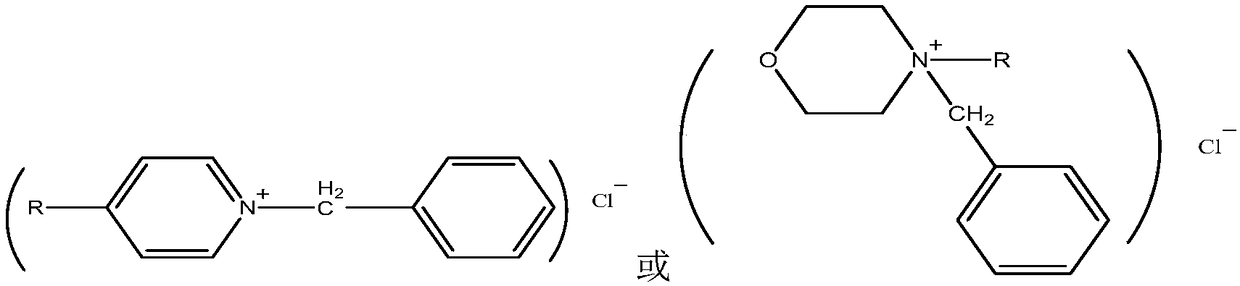

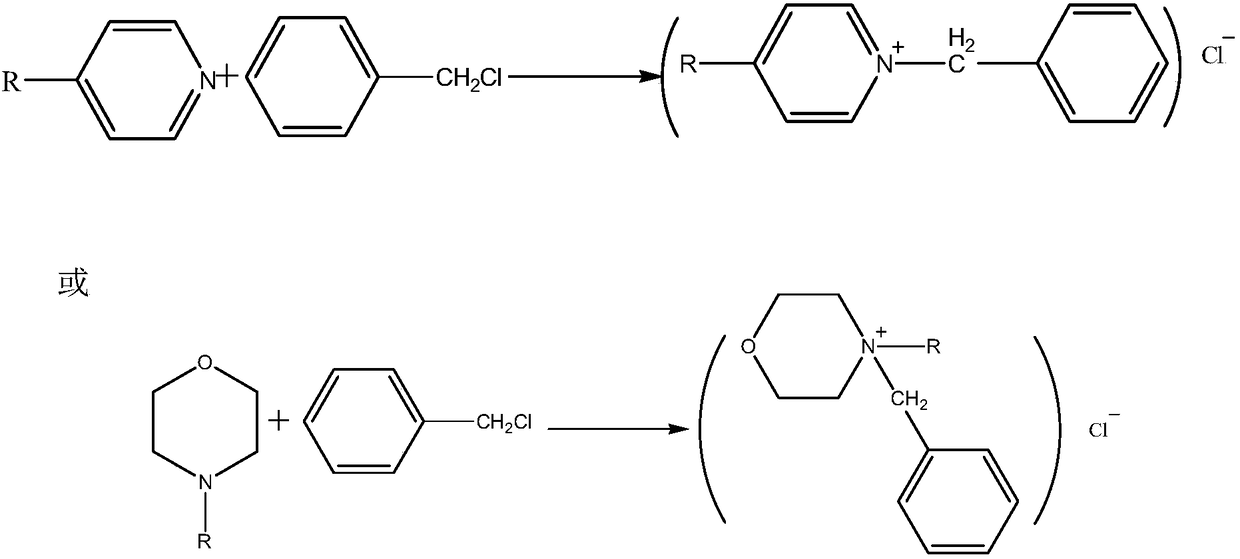

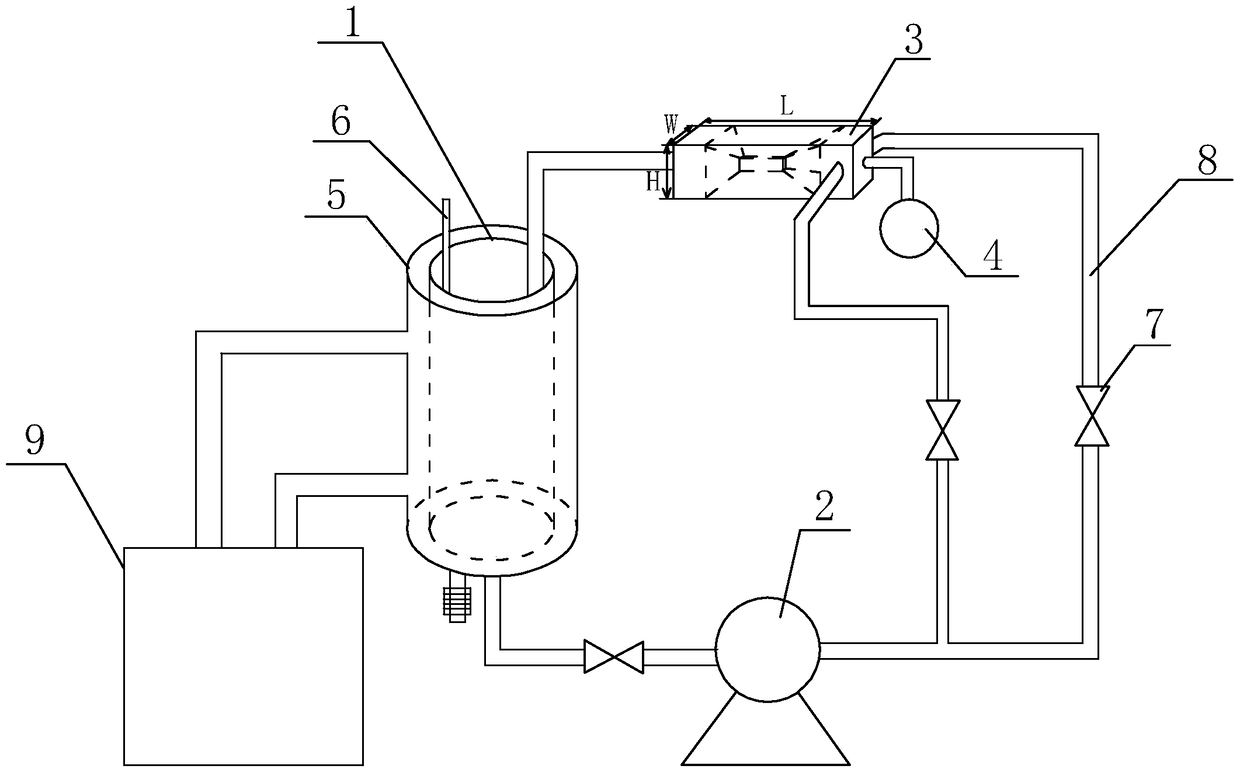

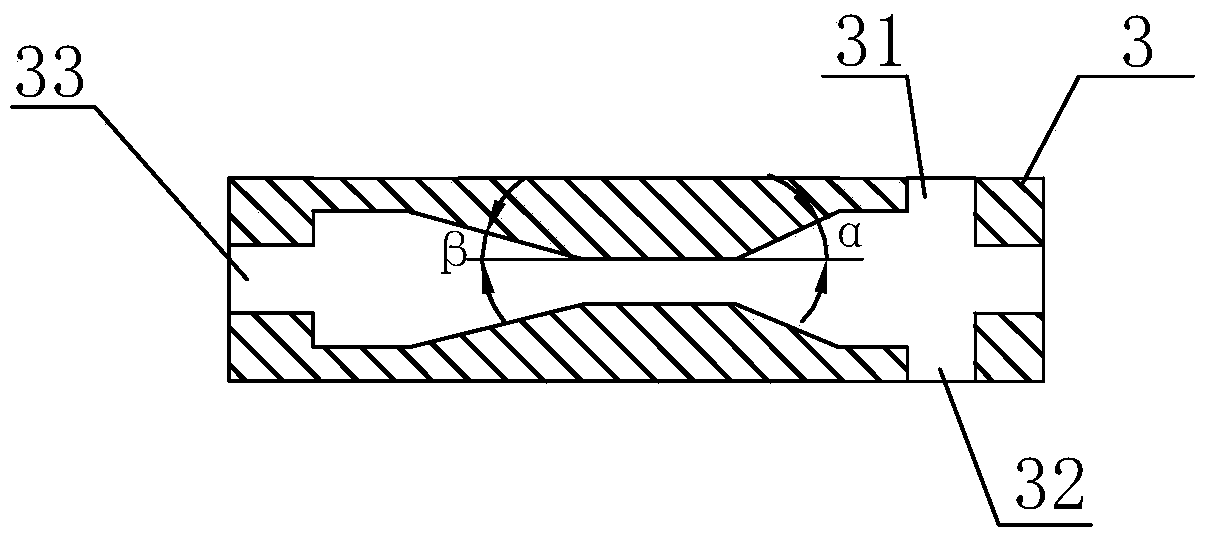

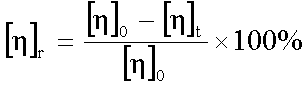

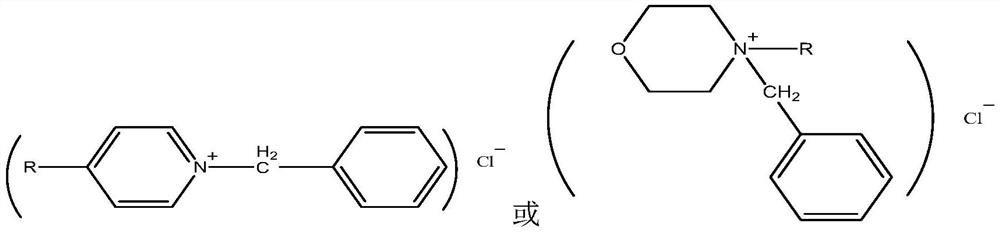

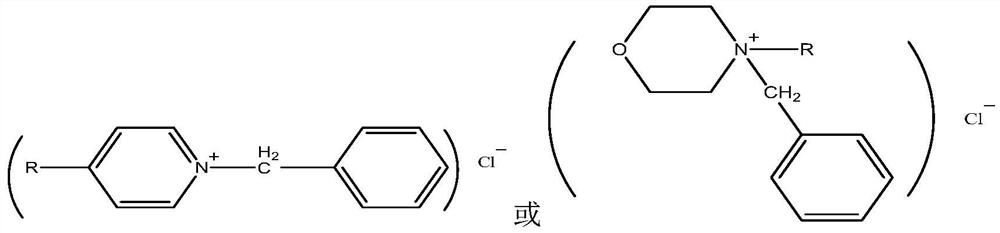

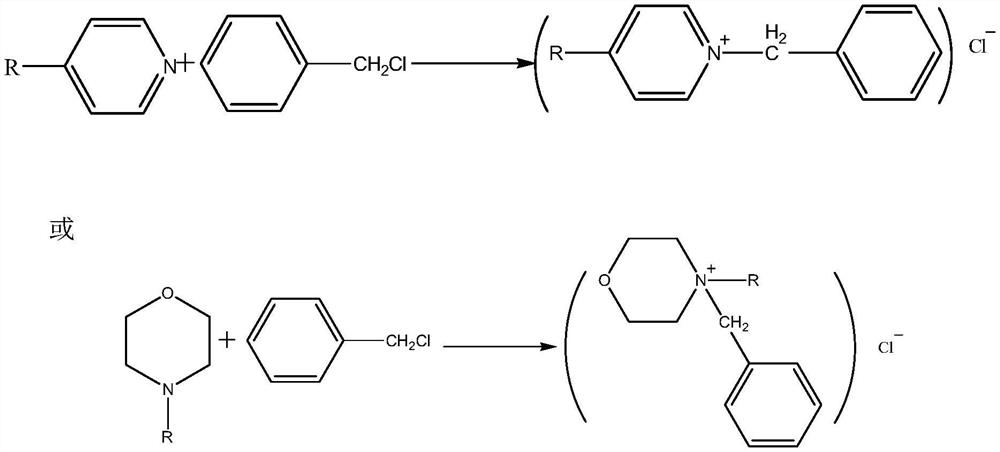

Corrosion inhibitor for clean diverting acid, and preparation method thereof

ActiveCN109251742AWill not reduce cleaning steering acid viscosityImprove anti-corrosion performanceOrganic chemistryDrilling compositionIodo fatty acidBenzyl chloride

The invention discloses a corrosion inhibitor for a clean diverting acid, and a preparation method thereof. The preparation method comprises the following steps: adding heterocyclic amine and benzyl chloride into a container under a pressure of 0.3-0.5 MPa according to a molar ratio of (1-1.2):1, adding isopropanol, heating the container to 120-130 DEG C, and carrying out a heat-insulation reaction for 4-6 h to obtain a quaternary ammonium salt of the heterocyclic amine; and uniformly mixing, by mass, 10-15% of saturated fatty acid, 3-5% of butynediol, 3-5% of a surfactant, 45-64% of a solventand 20-30% of the above main agent to obtain the corrosion inhibitor for the clean diverting acid. The corrosion inhibitor for the clean diverting acid has an excellent protection effect on carbon steel oil tubes and devices in a clean diverting acid environment, and does not reduce the viscosity of the acid solution system. The product solves the corrosion problem of the clean diverting acid system during the acidification fracturing operation, achieves the purpose of oil tube protection, and meets industry standards.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of preparation method of low viscosity sodium carboxymethyl cellulose

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

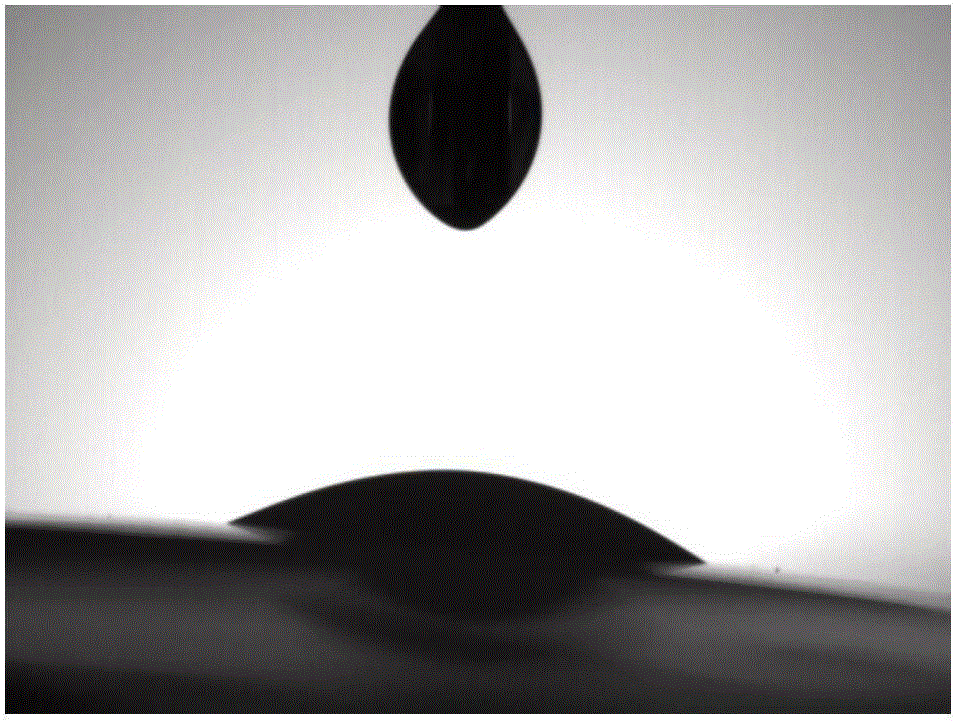

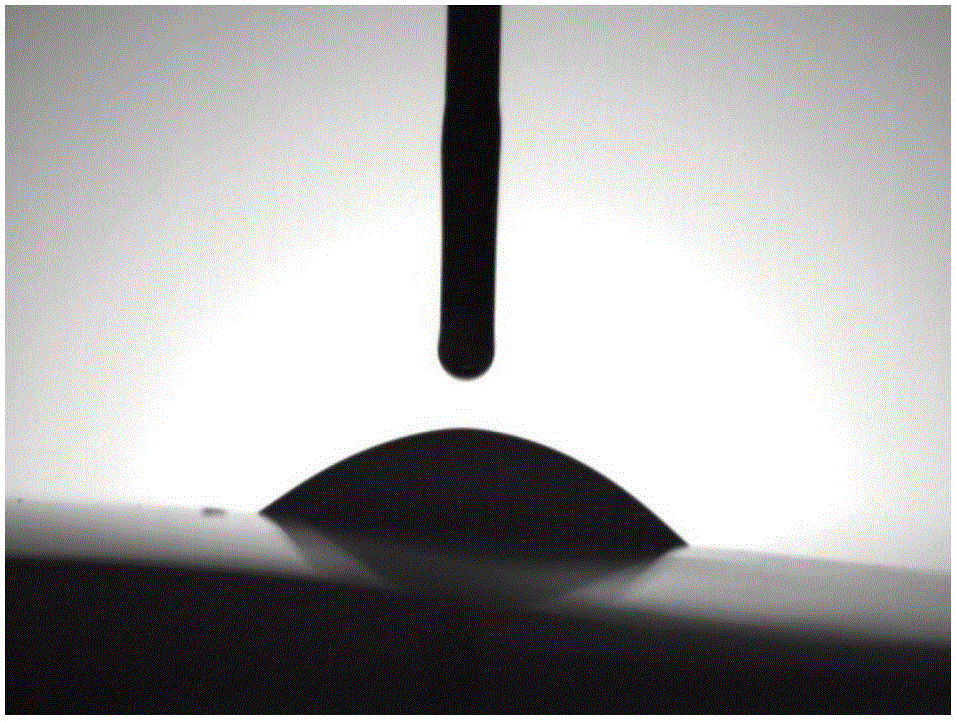

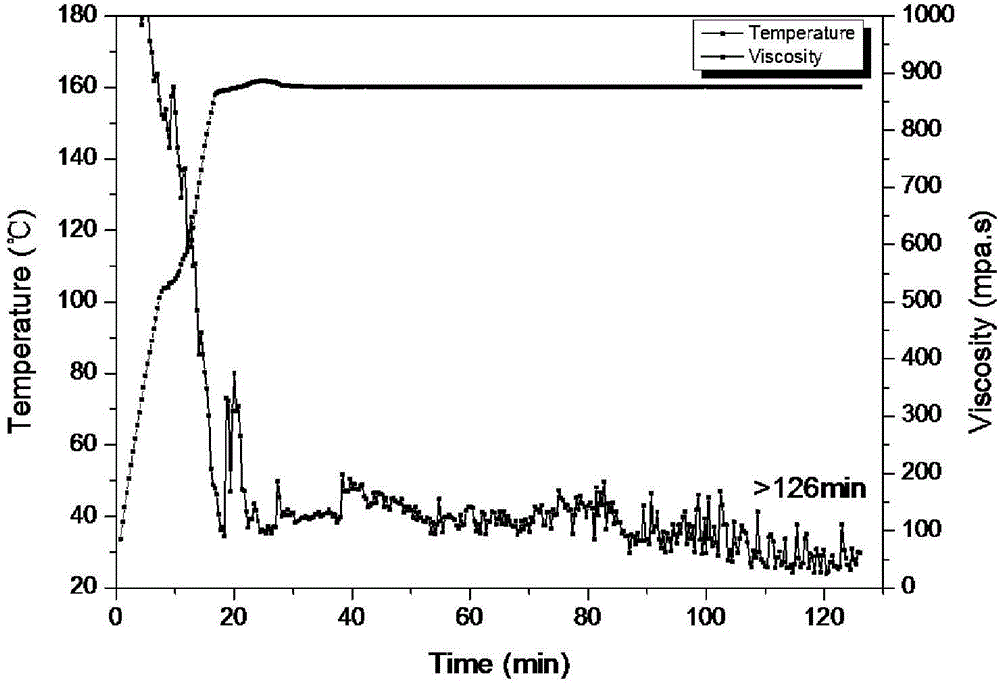

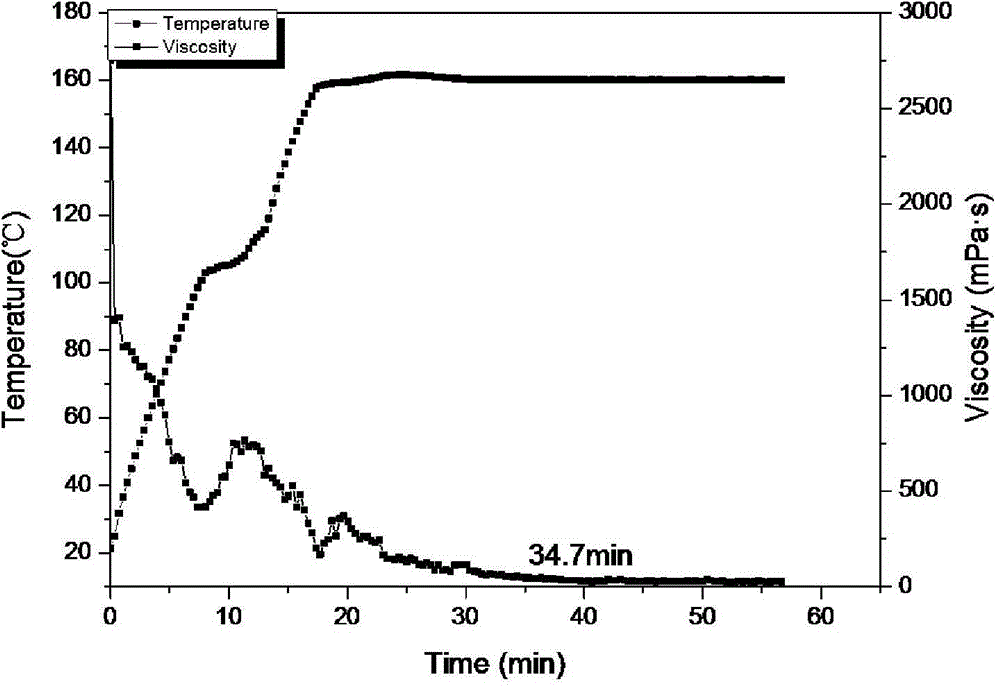

Self-adhesive polyurethane gel composite material and preparation method thereof

The invention discloses a self-adhesive polyurethane gel composite material. The self-adhesive polyurethane gel composite material is prepared from the following raw materials in parts by weight: 60 to 100 parts of a tripolymer, 2 to 20 parts of a curing agent and 2 to 25 parts of a plasticizer; the tripolymer is obtained by taking polyol, hexamethylene diisocyanate HDI and diphenyl-methane-diisocyanate MDI to react. The material is environment-friendly and has a high attaching property. The invention further provides a machining process of the self-adhesive polyurethane gel composite material; the machining process comprises the following steps: (1) heating the polyol, which is taken in parts by weight, to 50 DEG C to 70 DEG C; adding the diphenyl-methane-diisocyanate MDI, which is taken in parts by weight, to react for 20 minutes to 40 minutes; then adding the hexamethylene diisocyanate HDI which is taken in parts by weight; controlling the temperature to be 70 DEG C to 85 DEG C and reacting for 3 hours to 5 hours; standing for 20 hours to 48 hours and naturally cooling to finish the production of the tripolymer; (2) mixing three types of liquid-state substances including the tripolymer prepared by the step (1), and the curing agent and the plasticizer which are taken in parts by weight and stirring; leading a mixture into a mold, and heating and molding, wherein the temperature is selected in a range from 100 DEG C to 150 DEG C.

Owner:SHENZHEN LIXIN LUNAN RUBBER & PLASTIC HARDWARE

A kind of corrosion inhibitor for cleaning steering acid and preparation method thereof

ActiveCN109251742BWill not reduce cleaning steering acid viscosityImprove anti-corrosion performanceOrganic chemistryDrilling compositionActive agentBenzyl chloride

A corrosion inhibitor for cleaning steering acid and its preparation method, under the pressure of 0.3-0.5Mpa, heterocyclic amine and benzyl chloride are added to the container at a molar ratio of (1-1.2): 1, and then isopropanol is added , then warming up to 120‑130°C, heat preservation reaction for 4‑6h, to obtain heterocyclic amine quaternary ammonium salt; in terms of mass percentage, 10‑15% of saturated fatty acid, 3‑5% of butynediol, 3‑5% of surfactant 5%, 45%-64% of solvent and 20%-30% of the main agent are evenly mixed to obtain a corrosion inhibitor for cleaning steering acid. The corrosion inhibitor for cleaning diverting acid of the present invention can have excellent protection for carbon steel oil pipes and equipment in the environment of cleaning diverting acid, and will not reduce the viscosity of the acid liquid system. During the acid fracturing operation, this product solves the corrosion problem of the clean steering acid system, achieves the purpose of protecting the tubing, and meets industry standards.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of nonallergic rubber plaster plaster and preparation method thereof

ActiveCN109908112BAvoid allergiesImprove transdermal absorption rateHydroxy compound active ingredientsOil/fats/waxes non-active ingredientsMedicinal herbsPolymer science

The invention provides a non-allergic rubber plaster and a preparation method thereof, belonging to the technical field of plaster preparations. The rubber plaster plaster disclosed by the present invention comprises the following medicinal materials in parts by weight: 1-7 parts of Speranthus fragrans, 5-14 parts of Radix Aconiti Radix, 5-13 parts of Radix Aconiti Radix, 5-13 parts of Radix Aconitum, 5 parts of Radix Aconitum ‑13 parts, 5‑15 parts of Aracea, 5‑13 parts of Millet, 2‑10 parts of menthol, 1‑8 parts of camphor and 2‑10 parts of borneol. The non-allergic rubber plaster plaster provided by the invention uses polymer artificial rubber instead of natural rubber, which effectively solves the problem of allergies. The obtained rubber plaster plaster has a high transdermal absorption rate, can make the active ingredients of the medicine absorb faster, improve the therapeutic effect, and simultaneously make the plaster have high bonding performance and high stability.

Owner:INNER MONGOLIA HORQIN PHARMA CO LTD

Media, ornament, and method of making and storing same

PendingCN112663401AWon't breakWon't change colorSpecial paperPaper/cardboardAdhesiveStructural engineering

The present invention relates to an ornament, which has: a base layer having a first side and a second side opposite the first side, wherein the second side of the base layer is provided with a plurality of electrical ions; and a surface layer having a first side and a second side opposite to the first side, wherein the second side of the surface layer overlaps and covers the first side of the base layer, the surface layer is capable of mitigating electrical ion loss in the base layer in the event that the first side of the surface layer is in contact with the second side of the base layer in a form of at least a portion covering. According to the ornament disclosed by the invention, the ornament can be adhered to any smooth surface without using an adhesive, does not leave an adhesive mark or damage the plane surface when being torn off, is very environment-friendly and convenient to transport, can be repeatedly used multiple times during mounting, does not cause waste, can be cut and overlapped by using common scissors or a paper cutter, and can generate more visual effects and changes.

Owner:杨荣实

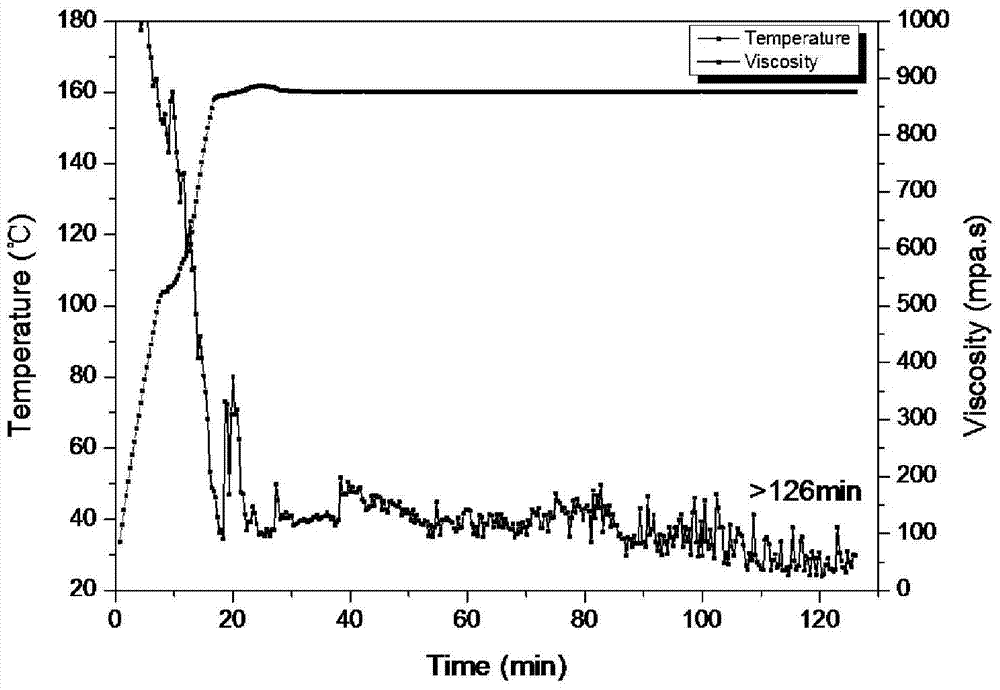

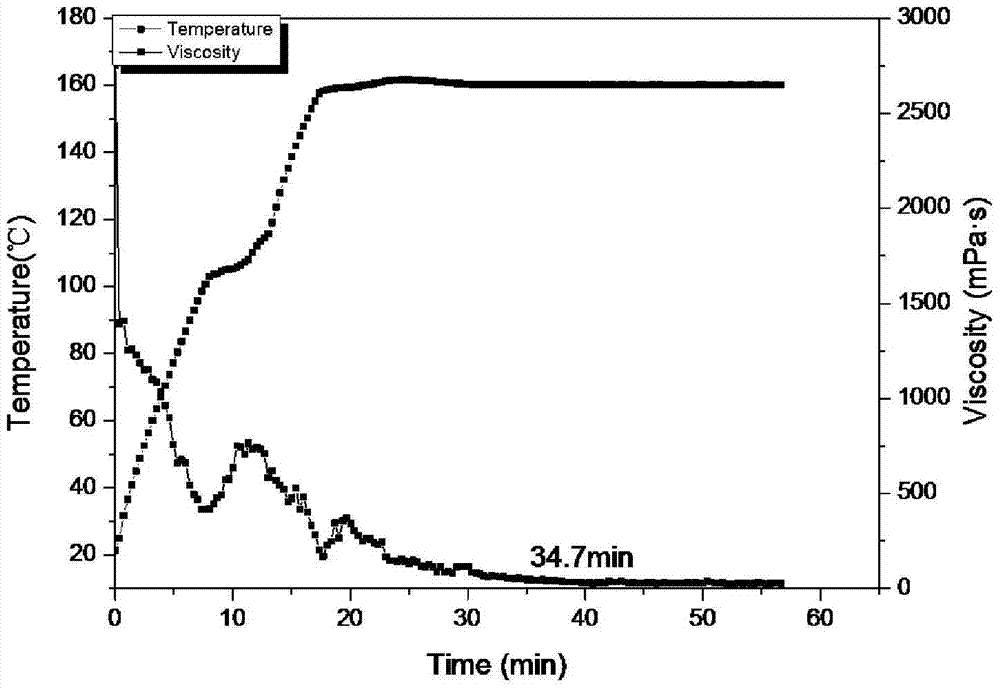

Thermally stable guar gum aqueous solution and its preparation method and application

The invention relates to a thermally stable guar gum aqueous solution which comprises guar gum or derivatives of guar gum, water, a pH adjustor and an antioxidant, wherein the pH of the aqueous solution system ranges from 7 to 11 and the antioxidant is one of the following combinations: (1) sulfite and gallic acid; (2) sulfite and gallate; and (3) sulfite, gallic acid and gallate. At the temperature of 130 DEG C to 200 DEG C and under an air condition, the viscosity of the solution is still greater than 50MPa.S in two hours.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Heat-insensitive thickener for pesticide water-base preparation and preparation method and application of thickener

InactiveCN102301999AGood water solubilityStrong ability to thicken water mediumBiocideAnimal repellantsSolubilityWater based

The invention discloses a heat-insensitive thickener for a pesticide water-base preparation and a preparation method and application of the thickener. The preparation method of the heat-insensitive thickener for the pesticide water-base preparation comprises the following steps of: performing polymerization reaction on a monomer (A) and a monomer (B) under the action of an initiator at the temperature of between 20 and 100 DEG C for 0.5 to 24 hours to obtain the heat-insensitive thickener for the pesticide water-base preparation, wherein the initiator is inorganic salts or azo; the monomer (A) is paste obtained by mixing isomerous tridecanol polyoxyethylene ether, methylbenzene, maleic acid and p-toluenesulfonic acid, heating, refluxing and co-boiling to remove redundant water and residual methylbenzene; and the monomer (B) is one or more of water-soluble monomers with unsaturated double bonds. The pesticide water-base preparation prepared from the heat-insensitive thickener for the pesticide water-base preparation has a good thickening effect and high surface activity, temperature resistance and water solubility, the thickening effect of the thickener cannot be reduced along with the rise of the temperature, and the viscosity of the water-base pesticide preparation can be increased.

Owner:YANGZHOU SPED CHEM

Antistatic flexible polyurea composition, preparation thereof, construction method and applications

ActiveCN101338017BViscosity does not decreaseImprove mechanical propertiesLiquid surface applicatorsAnti-corrosive paintsElastomerAntistatic agent

Owner:MARINE CHEM RES INST CO LTD

Self-adhesive polyurethane gel composite material and preparation method thereof

The invention discloses a self-adhesive polyurethane gel composite material. The self-adhesive polyurethane gel composite material is prepared from the following raw materials in parts by weight: 60 to 100 parts of a tripolymer, 2 to 20 parts of a curing agent and 2 to 25 parts of a plasticizer; the tripolymer is obtained by taking polyol, hexamethylene diisocyanate HDI and diphenyl-methane-diisocyanate MDI to react. The material is environment-friendly and has a high attaching property. The invention further provides a machining process of the self-adhesive polyurethane gel composite material; the machining process comprises the following steps: (1) heating the polyol, which is taken in parts by weight, to 50 DEG C to 70 DEG C; adding the diphenyl-methane-diisocyanate MDI, which is taken in parts by weight, to react for 20 minutes to 40 minutes; then adding the hexamethylene diisocyanate HDI which is taken in parts by weight; controlling the temperature to be 70 DEG C to 85 DEG C and reacting for 3 hours to 5 hours; standing for 20 hours to 48 hours and naturally cooling to finish the production of the tripolymer; (2) mixing three types of liquid-state substances including the tripolymer prepared by the step (1), and the curing agent and the plasticizer which are taken in parts by weight and stirring; leading a mixture into a mold, and heating and molding, wherein the temperature is selected in a range from 100 DEG C to 150 DEG C.

Owner:SHENZHEN LIXIN LUNAN RUBBER & PLASTIC HARDWARE

Thermally stable guar gum aqueous solution and preparation method and application thereof

ActiveCN104449645ALow viscosityViscosity does not decreaseDrilling compositionGallic acid esterSulfite

The invention relates to a thermally stable guar gum aqueous solution which comprises guar gum or derivatives of guar gum, water, a pH adjustor and an antioxidant, wherein the pH of the aqueous solution system ranges from 7 to 11 and the antioxidant is one of the following combinations: (1) sulfite and gallic acid; (2) sulfite and gallate; and (3) sulfite, gallic acid and gallate. At the temperature of 130 DEG C to 200 DEG C and under an air condition, the viscosity of the solution is still greater than 50MPa.S in two hours.

Owner:INST OF CHEM CHINESE ACAD OF SCI

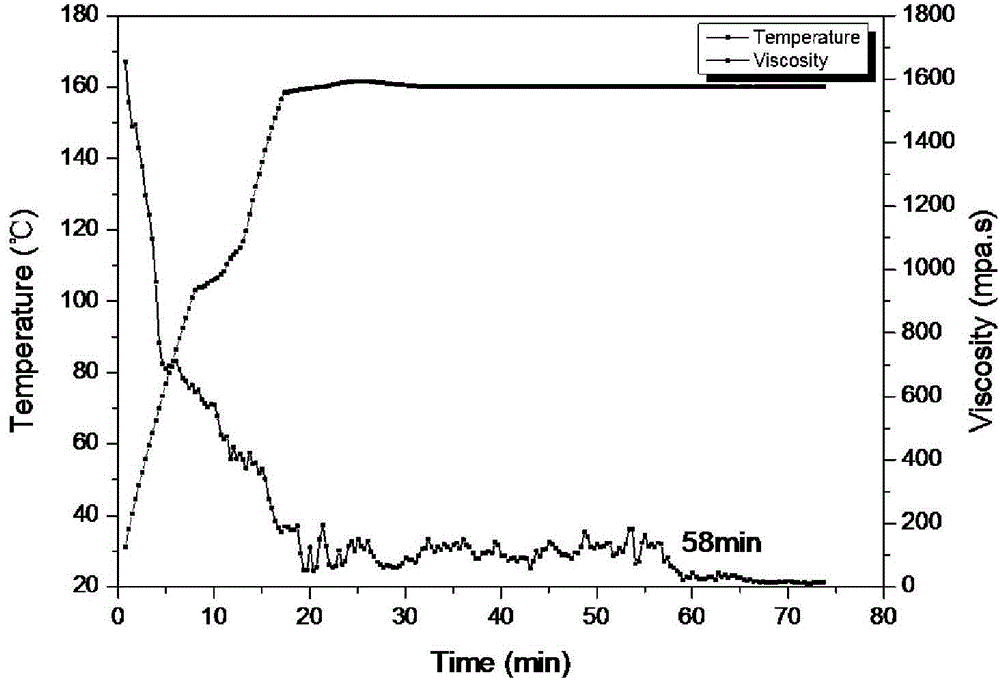

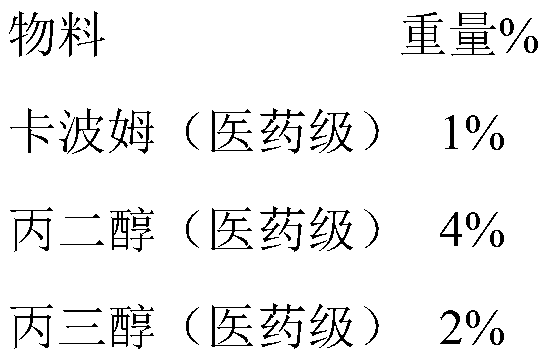

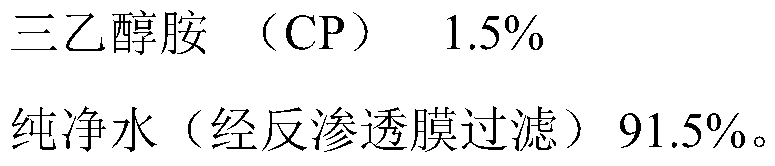

A method for preparing medical ultrasonic couplant sterile product that can be used safely

ActiveCN110559457BViscosity does not decreaseChemically stableEchographic/ultrasound-imaging preparationsHeatPolyesterPolyamide

The invention discloses a safe use method for preparing a medical ultrasonic coupling agent sterile product, wherein the method comprises the following steps: S1, putting an unsterilized medical ultrasonic coupling agent material into a stainless steel barrel, and carrying out steam sterilization, wherein the formula of the medical ultrasonic coupling agent material comprises 0.5-1.5% of carbomer,3-5% of propylene glycol, 1-3% of glycerol, 1-2% of triethanolamine, and the balance being purified water; S2, after sterilization, cooling the medical ultrasonic coupling agent material to 25 DEG C-80 DEG C, and packaging, wherein a packaging bag is an aluminum composite film packaging bag, the aluminum composite film packaging bag is of a four-layer film structure, and four layers of films sequentially comprise a polyester layer, an aluminum foil layer, a polyamide or Kevlar layer and a polyethylene or polypropylene layer from outside to inside; and S3, after packaging is completed, carrying out terminal thermal sterilization. For facilitating the use of an operating table, a layer of specially-made paper-plastic bag is sleeved on an aluminum composite film packaging bag of a common sterile product, and then sterilization is carried out again. Compared with other methods, the safe use method is simple to operate, good in product quality and low in production cost.

Owner:广州广工技术开发有限公司

A kind of transfer substrate, transfer method and transfer equipment of light-emitting diode

ActiveCN110265348BLow viscosityReduce viscositySemiconductor/solid-state device testing/measurementSolid-state devicesLaser cuttingReflective layer

The invention discloses a transfer substrate, a transfer method of a light-emitting diode, and a transfer device. The transfer substrate includes: a base, a reflective layer located on one side of the base, an optical conversion layer located on the side of the reflective layer away from the base, and a base located on the optical conversion layer. A light-sensitive anti-adhesion film on the side facing away from the reflective layer; an optical conversion layer for converting a certain wavelength range of light into non-visible light; a light-sensitive anti-adhesion film for bonding LEDs and reducing the viscosity to release the LEDs after exposure to non-visible light . Using the above-mentioned transfer substrate can complete the transfer and detection of the light-emitting diodes at the same time, and find and remove the abnormally luminous light-emitting diodes before the bonding process, avoiding the problems that the abnormally luminous light-emitting diodes are difficult to remove and the laser cutting process damages the array substrate. The transshipment process is simplified, and the yield and efficiency of transshipment are improved. In addition, there is no need to add an additional non-visible light source, the structure is simple, and the detection cost is low.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

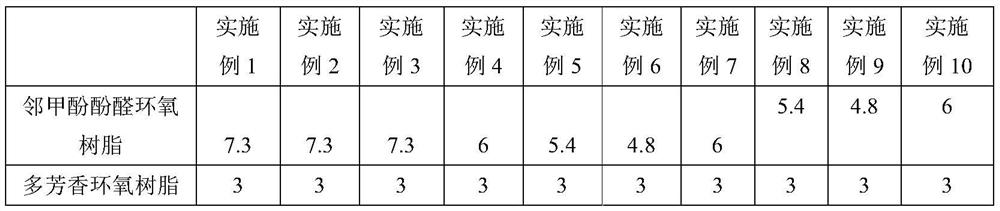

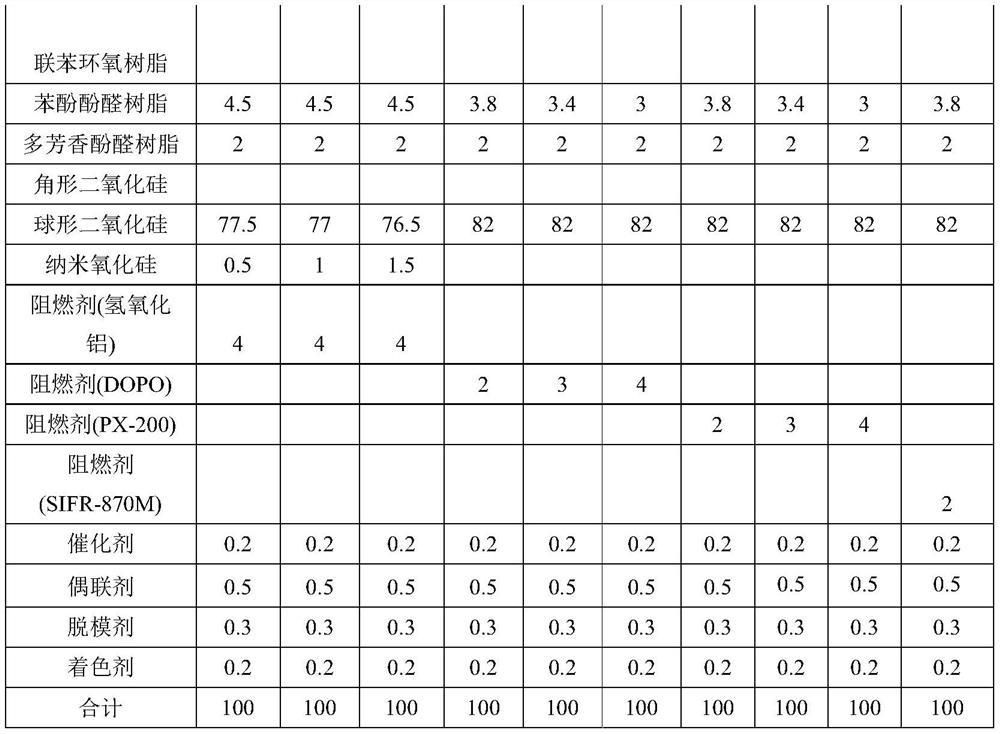

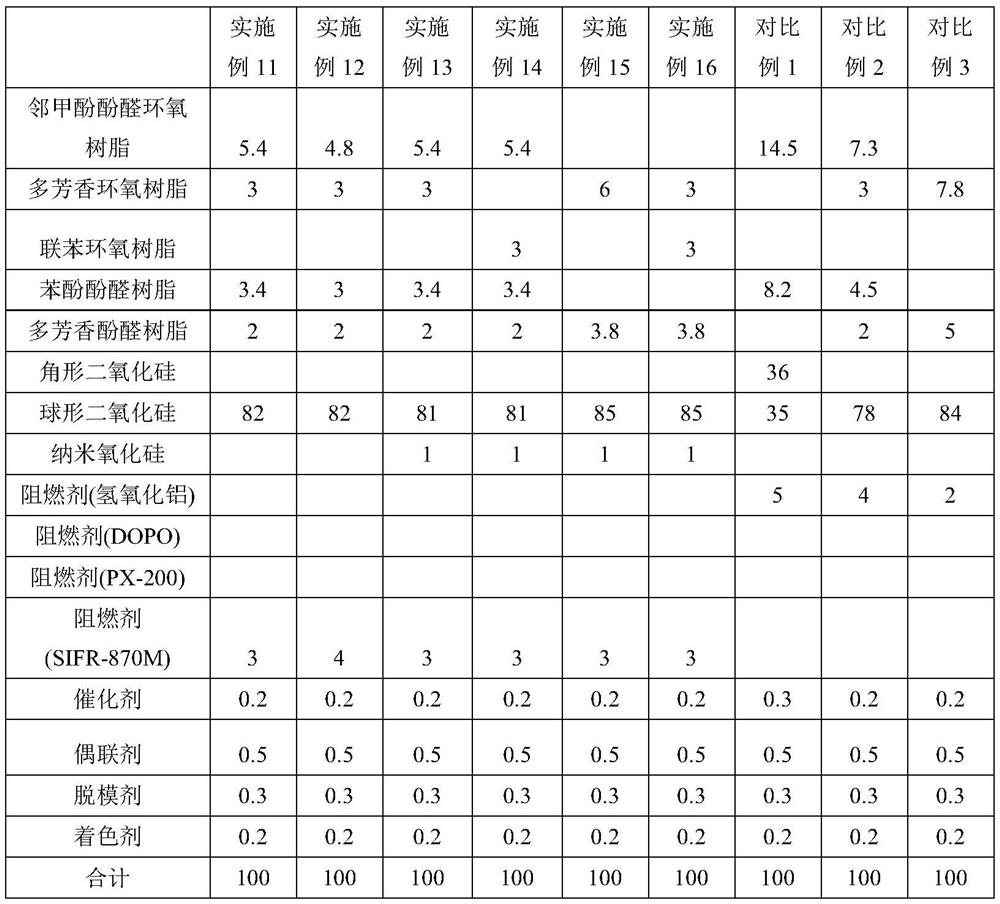

High-fluidity and low-viscosity epoxy resin composition and preparation method thereof

The invention belongs to the technical field of C08L63 / 00, and particularly relates to a high-fluidity and low-viscosity epoxy resin composition and a preparation method thereof. The high-fluidity and low-viscosity epoxy resin composition at least comprises the following preparation raw materials: epoxy resin, a curing agent, an inorganic filler, a modifier and a flame retardant. The high-fluidity and low-viscosity epoxy resin composition prepared by the invention is green and environment-friendly, is safe and pollution-free in the use process, and meets the environment-friendly requirement; and when the high-fluidity and low-viscosity epoxy resin composition prepared by the invention is used in electronic components, high temperature can be borne, and the problems of insufficient filling and line punching can be avoided.

Owner:上海道宜半导体材料有限公司

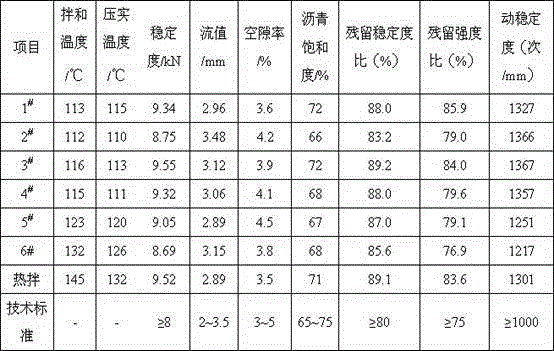

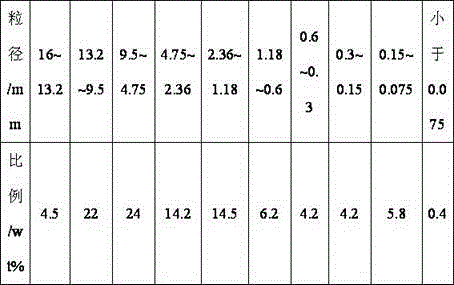

A kind of non-ionic liquid crystal asphalt warm mix agent and preparation method thereof

ActiveCN104559237BLess irritatingImprove stabilityClimate change adaptationBuilding insulationsFatty alcoholIonic liquid

The invention discloses a non-ionic liquid crystal asphalt warm mixing agent and a preparation method thereof. The asphalt warm mixing agent comprises the following components in parts by weight: 3.5-55.5 parts of polyglycerol fatty acid ester, 0.1-20 parts of fatty alcohol and 24.5-96.4 parts of water. The preparation method comprises the following steps: (1) uniformly mixing water and polyglycerol fatty acid ester in a container according to the ratio; (2) adding fatty alcohol into the mixture obtained in the step (1) for uniform mixing, and leaving the mixture to stand for a period of time to obtain the non-ionic liquid crystal asphalt warm mixing agent. The non-ionic liquid crystal asphalt warm mixing agent disclosed by the invention can effectively reduce the high-temperature viscosity of asphalt and has the advantages of stable performance, available raw material, simple and convenient preparation method, wide application range and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com