Alkali-resisting polymer for displacement of reservoir oil of oil field and preparation method thereof

A polymer and alkali-resistant technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as viscosity reduction, temperature resistance, and viscosity increase ability, and achieve good viscosity increase and thermal stability. The effect of good chemical stability and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

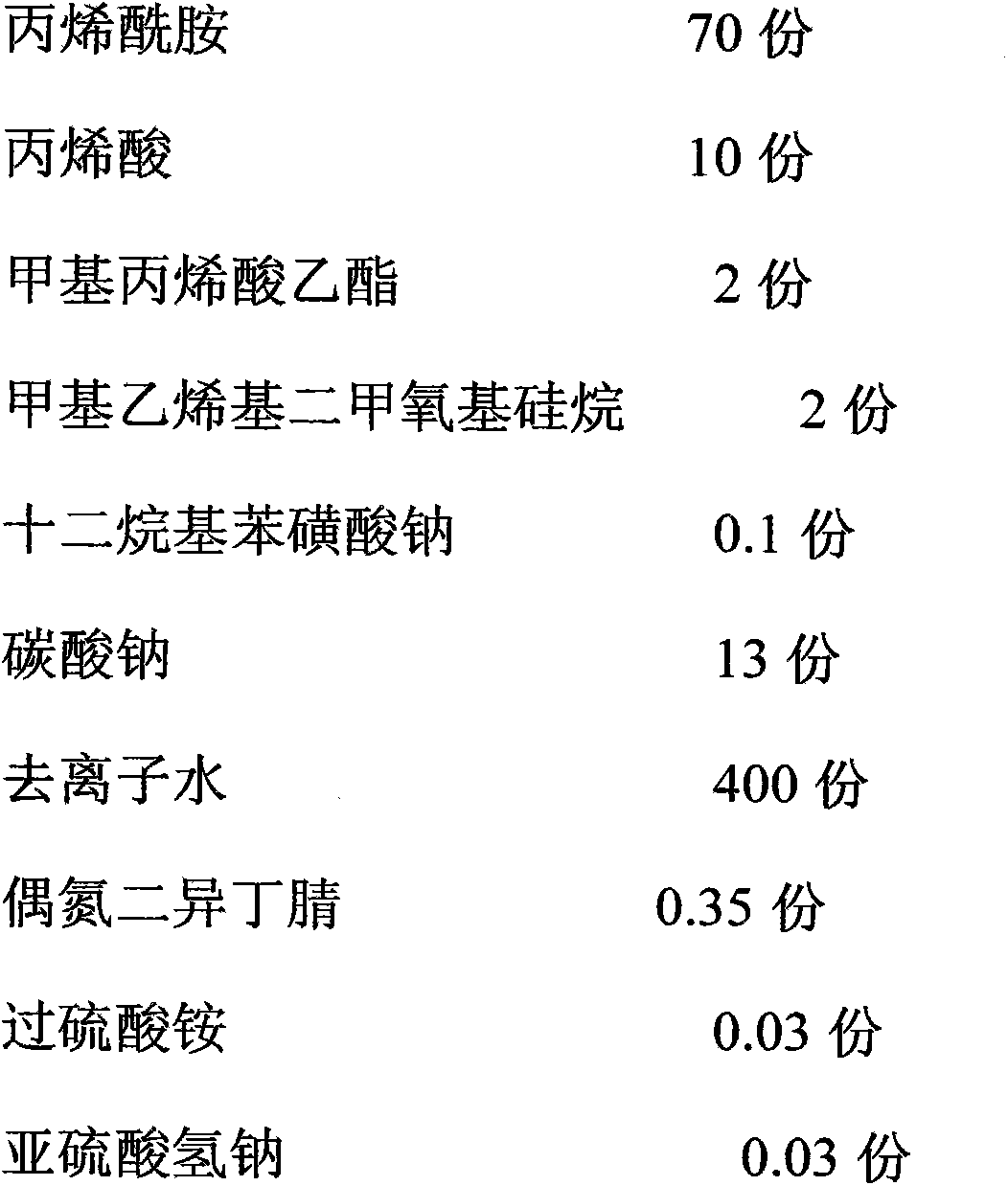

[0024] 1.1 The raw material composition (parts by weight) of the alkali-resistant polymer used for oil field displacement of the present invention:

[0025]

[0026] 1.2 The preparation method of the alkali-resistant polymer used for oil field displacement of the present invention:

[0027] Dissolve acrylamide in deionized water to make an aqueous solution, add sodium carbonate and stir evenly, add anionic monomers, hydrophobic monomers, alkali-resistant monomers, and surfactants, stir evenly, transfer to the reactor, and add 1 #Initiator, continue to pass nitrogen for 10 minutes and add 2# initiator, add nitrogen for 10 minutes to add 3# initiator, continue to pass nitrogen until the reaction system has a temperature of 1-2 ° C, stop nitrogen, and wait for the reaction system to reach a peak temperature of 85-95 ℃, heat preservation for 6 hours, cutting, granulation, drying and crushing to obtain the alkali-resistant polymer of the present invention.

Embodiment 2

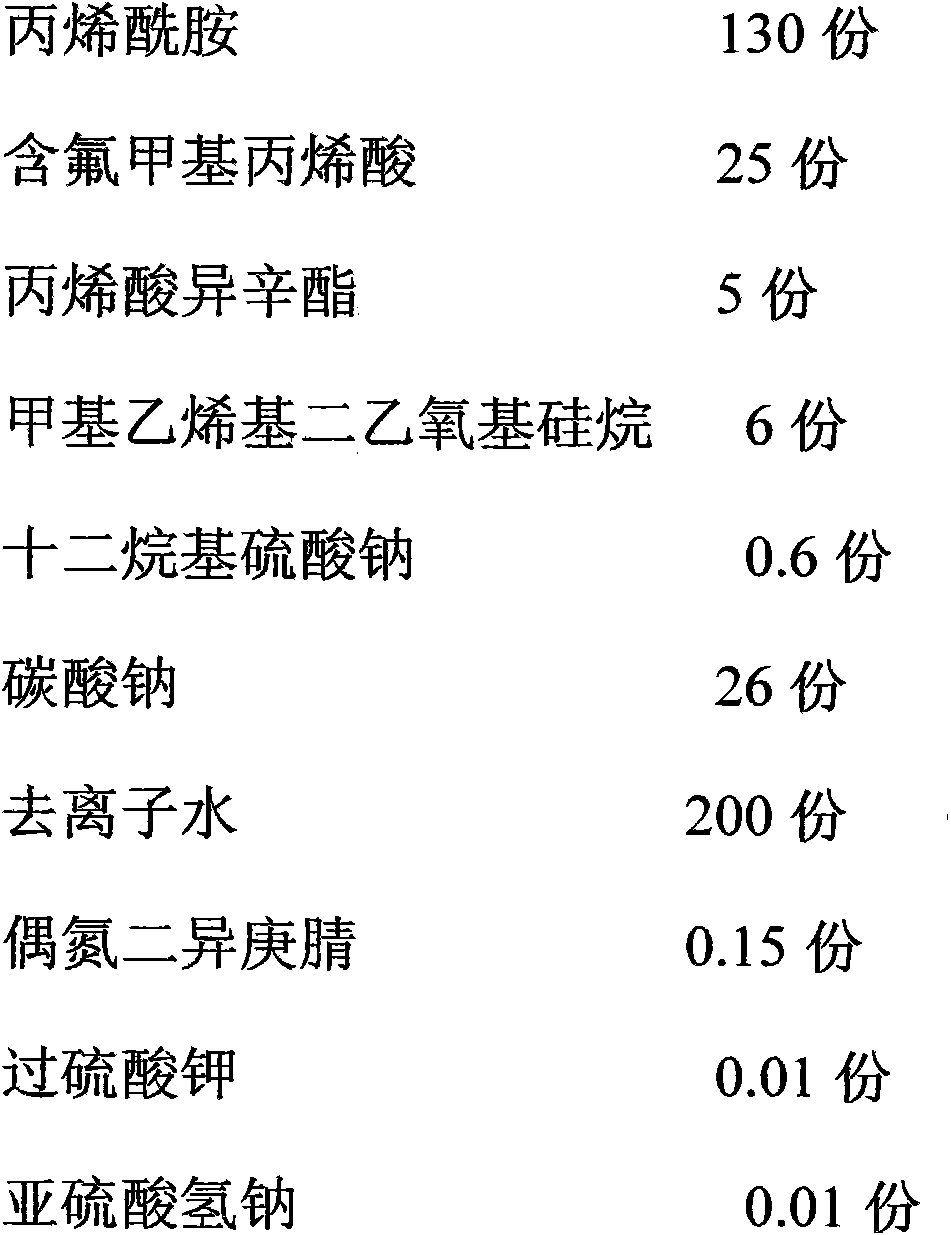

[0029] 2.1 The raw material composition (parts by weight) of the alkali-resistant polymer used for oil field displacement of the present invention:

[0030]

[0031] 2.2 The preparation method of the alkali-resistant polymer used for oil field displacement of the present invention:

[0032] 1.2 with embodiment 1.

Embodiment 3

[0034] 3.1 The raw material composition (parts by weight) of the alkali-resistant polymer used for oil field displacement of the present invention:

[0035]

[0036]

[0037] 3.2 The preparation method of the alkali-resistant polymer used for oil field displacement of the present invention:

[0038] 1.2 with embodiment 1.

[0039] The polymer prepared by embodiment 1-3 is carried out viscosity measurement, method and result are as follows:

[0040] Determination method: the polymer is formulated into a 5000ppm solution, diluted with 1.2% sodium hydroxide solution to a solution with a concentration of 1000ppm, and the viscosity is measured with a DV-III viscometer at 45°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com