Xanthomonas, preparation method thereof and method thereof for producing temperature resistant xanthan gum polysaccharide

A technology of xanthomonas and xanthan gum, applied in the field of xanthomonas, can solve the problems of product quality decline, poor temperature resistance, unstable viscosity of aqueous solution, etc., and achieve product viscosity increase, good temperature resistance, Effect of improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

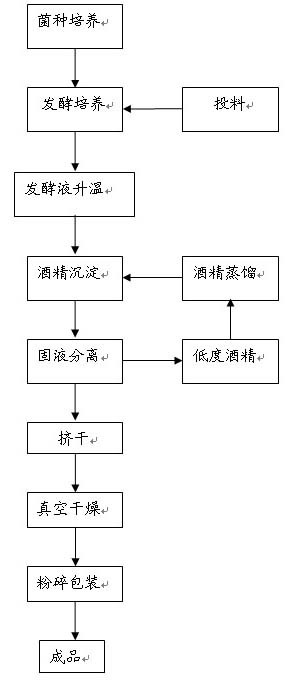

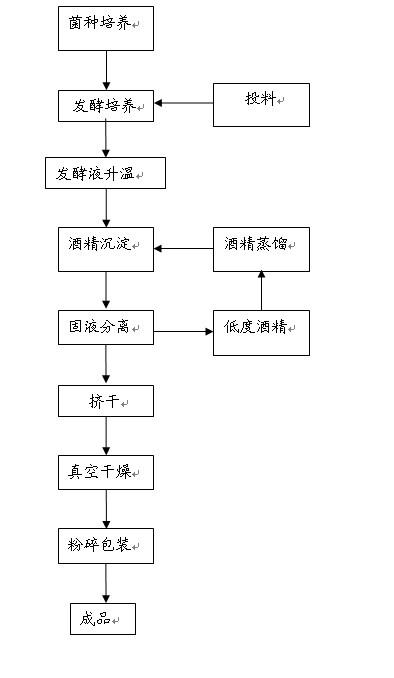

Method used

Image

Examples

Embodiment 1

[0046] (1) Breeding of temperature-resistant strains

[0047] ①. Preparation of Xanthomonas bacterial suspension:

[0048] Inoculate Xanthomonas in seed shake flasks, culture with shaking at 28±1°C for 18-24 hours, centrifuge the seed solution several times and wash it with buffer to make a bacterial suspension, in which the seed medium is The components are proportioned by weight with 1% sucrose, 0.3% beef extract, and 0.5% yeast powder, and the pH is adjusted to 7.0±0.2.

[0049] ②. Nitrosoguanidine mutagenesis

[0050] Add dissolved nitrosoguanidine to the bacterial suspension and treat it for 1-1.5 hours, centrifuge and wash the treated bacterial suspension several times, then dilute and spread it on a plate, and cultivate it at 36-38°C for three days.

[0051] ③. UV mutagenesis

[0052] Pick strong and good colonies after nitrosoguanidine mutagenesis, culture them in shake flasks, and then make a bacterial suspension. Take 5ml of the bacterial suspension and place it ...

Embodiment 2

[0057] (1) Expanded cultivation of seeds:

[0058] ①. First-class seed tank:

[0059] Put the components of the seed medium into the first-level seed tank with water in turn according to the weight ratio (1% sucrose, 0.3% beef extract, and 0.5% yeast powder), stir evenly to dissolve, and adjust the pH to 7.0±0.2 ;Using real disinfection, the temperature is 121°C, the pressure is 0.1Mpa, and the time is 45 minutes; when the temperature is lowered to 28±1°C, under sterile conditions, inoculate at a rate of 1% from the inoculation port, and the bacteria after inoculation are at 28±1°C Under certain conditions, cultivate for 24 hours, use a biological microscope to detect the growth of the bacteria, and replant when the number of bacteria is large and the growth is full;

[0060] ②. Secondary seed tank:

[0061] Put the components of the seed medium into the secondary seed tank with water in turn according to the weight ratio (1% sucrose, 0.3% beef extract, 0.5% yeast powder), s...

Embodiment 3

[0065] (1) Expanded cultivation of seeds:

[0066] ①. First-class seed tank:

[0067] Put the components of the seed medium into the first-level seed tank with water in turn according to the weight ratio (sucrose 1.2%, beef extract 0.4%, yeast powder 0.6%), stir evenly to dissolve, adjust the pH to 7.0±0.2 ;Using real disinfection, the temperature is 121°C, the pressure is 0.12Mpa, and the time is 50 minutes; when the temperature is lowered to 28±1°C, under sterile conditions, the inoculation port is inoculated at a ratio of 1.2%, and the bacteria after inoculation are at 28±1°C Under the conditions of 20 hours, use a biological microscope to detect the growth of the bacteria, and when the number of bacteria is large and the growth is full, replant;

[0068] ②. Secondary seed tank:

[0069] Put the components of the seed medium into the secondary seed tank with water in turn according to the weight ratio (sucrose 1.2%, beef extract 0.4%, yeast powder 0.6%), stir evenly to di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com