Corrosion inhibitor for clean diverting acid, and preparation method thereof

A technology that turns to acid and corrosion inhibitors, applied in chemical instruments and methods, earthwork drilling, wellbore/well parts, etc., can solve serious problems such as not being able to maintain viscosity, and achieve good stability, no viscosity reduction, and anti-corrosion excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of above-mentioned cleaning steer acid corrosion inhibitor is:

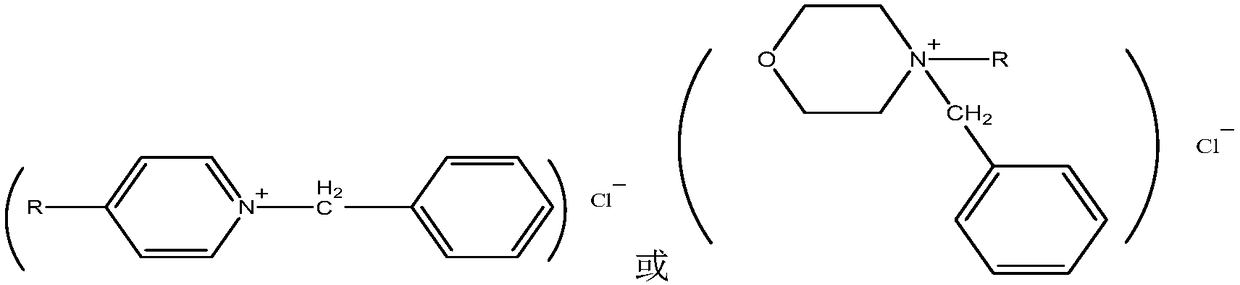

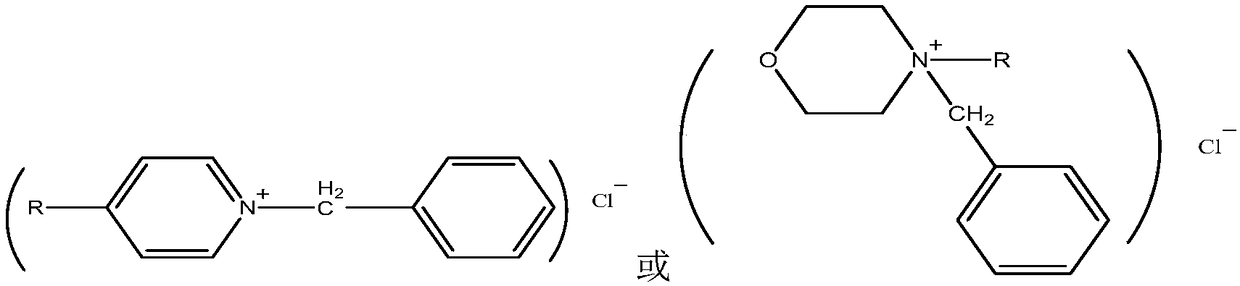

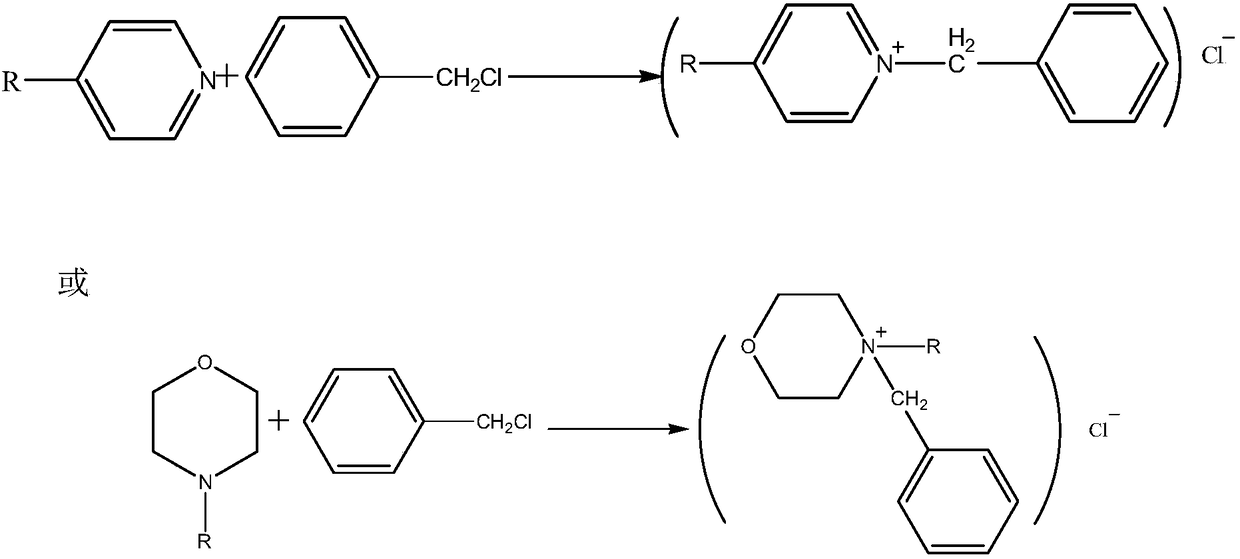

[0037] First prepare the heterocyclic amine quaternary ammonium salt: the heterocyclic amine quaternary ammonium salt is prepared by the following process: under the pressure of 0.3-0.5Mpa, add the heterocyclic amine and benzyl chloride into the container at a molar ratio of 1-1.2:1, Then add isopropanol, then heat up to 120-130°C, keep warm for 4-6h to obtain quaternary ammonium salt of heterocyclic amine, wherein isopropanol accounts for 80% of the total mass of heterocyclic amine and benzyl chloride, the reaction formula is as follows ;

[0038]

[0039] The heterocyclic amine is a quinoline compound, a pyridine compound or a morpholine compound. Among them, the quinoline compound is quinoline or isoquinoline; the pyridine compound is pyridine, 2-picoline (α-picoline), 3-picoline (β-picoline) or 4-methylpyridine Pyridine (γ-picoline); morpholine compounds are N-methylmorpholi...

Embodiment 1

[0044] In this example, the preparation of the corrosion inhibitor for cleaning fracturing acid is divided into two steps: the first step is the synthesis of quinoline quaternary ammonium salt as the main agent, and the second step is the preparation of the corrosion inhibitor.

[0045] Under the pressure of 0.3-0.5Mpa, add quinoline and benzyl chloride into a three-necked flask at a molar ratio of 1:1, then add isopropanol (accounting for 80% of the total mass of quinoline and benzyl chloride) and mix evenly to heat up , turn on the cooling circulation system, ensure that the heating rate is not higher than 20°C / 10min, raise the temperature from room temperature to 120-130°C, and keep the temperature for 6 hours to obtain quinoline quaternary ammonium salt;

[0046]Then according to mass percentage, quinoline quaternary ammonium salt 20%, n-hexanoic acid 10%, butynediol 5%, ricinoleic acid polyoxyethylene ether 3%, water 22% and isopropanol 40% are mixed uniformly, obtain Cor...

Embodiment 2

[0054] Under the pressure of 0.3-0.5Mpa, add isoquinoline and benzyl chloride into the three-necked flask at a molar ratio of 1.2:1, then add isopropanol (accounting for 80% of the total mass of isoquinoline and benzyl chloride) and mix well Heating to raise the temperature, turn on the cooling circulation system, ensure that the heating rate is not higher than 20°C / 10min, raise the temperature to 120-130°C, and keep it warm for 6 hours to obtain quinoline quaternary ammonium salt;

[0055] Then, according to mass percentage, 25% of quinoline quaternary ammonium salt, 10% of lauric acid, 3% of butynediol, 5% of polyoxyethylene laurate, 20% of water and 37% of isopropanol were mixed uniformly to obtain a clean Corrosion inhibitor for steering acid, code TG204-2;

[0056] According to the test method and conditions in Example 1, the test was carried out. The results show that the corrosion rate of TG204-2 corrosion inhibitor in clean diverting acid is 21g / m 2 ·h, meet the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com