Antistatic flexible polyurea composition, preparation thereof, construction method and applications

A composition, antistatic technology, applied in the direction of polyurea/polyurethane coatings, conductive coatings, coatings, etc., can solve the problems of limited application scope, antistatic properties, mixing and mechanical properties of polyurea elastomers are difficult to balance, etc. Achieve the effect of improving antistatic properties, ensuring storage stability, and improving the degree of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

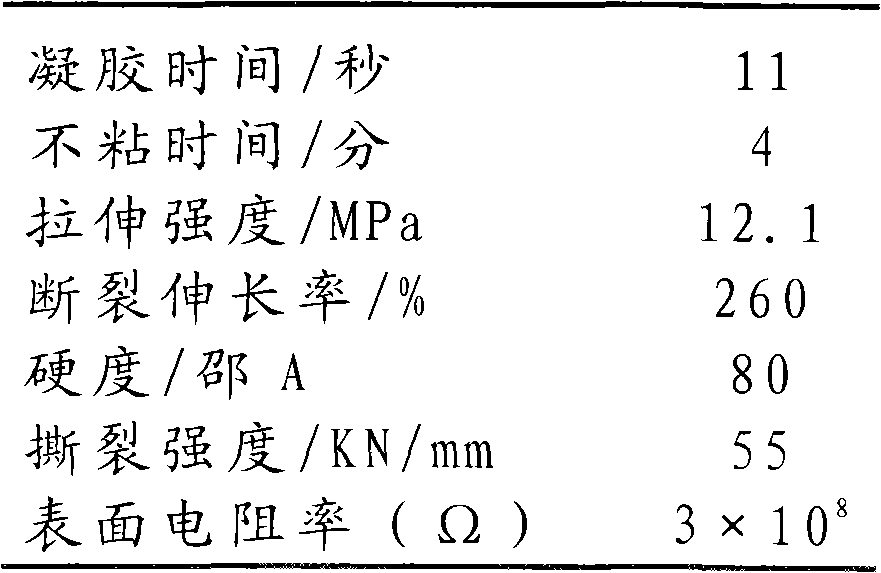

[0047] Synthesis of component A: Add 49 parts of MDI-50 into the reaction kettle, fill it with nitrogen, stir at a constant speed, heat to 60°C, add 31 parts of polyol 220 to the kettle dropwise, keep it warm while stirring, after the dropwise addition, After heat preservation at 80°C for 3 hours, add 20 parts of antistatic agent, heat preservation for 1 hour, take a sample to measure the free isocyanate content (i.e. NCO%) is 15%, cool and discharge, which is the A component;

[0048] Prepare R component: 10 parts of JEFFAMINE T-5000, 32 parts of JEFFAMINE D-2000, 26 parts of diethyltoluenediamine (DETDA), 10 parts of conductive carbon black, 20 parts of conductive mica, 0.5 parts of Irganox 1076 and 0.5 parts Tinuvin 328 is composed of pigments, fillers, additives, antistatic agents, and part of the amino-terminated polyether on a three-roll machine. After the fineness reaches ≤45 μm, the grinding slurry is put into the reaction kettle, and the remaining amine-terminated poly...

Embodiment 2

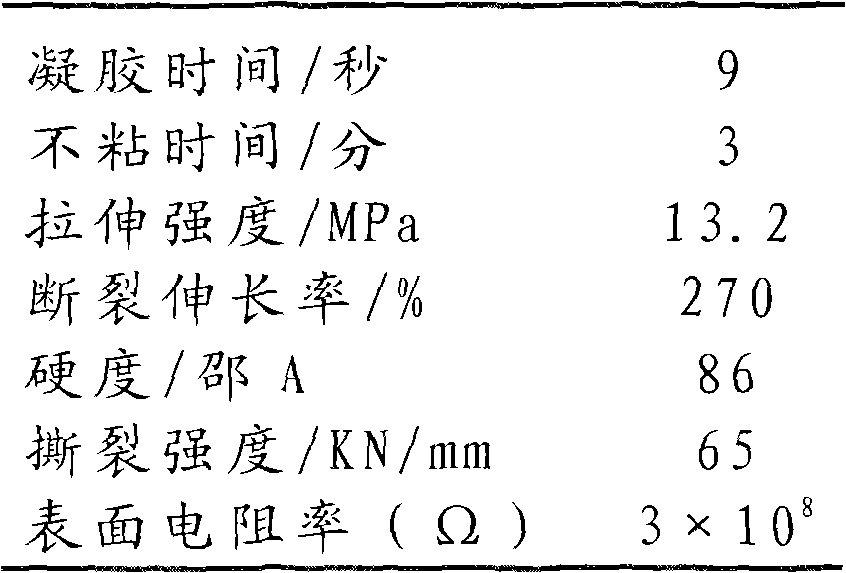

[0054] Synthesize 49 parts of MDI-50, 31 parts of polyether polyol 220, and 20 parts of conductive mica according to the process in this patent to obtain a prepolymer with an NCO% of 15%, which is component A. R component is composed of 10 parts of JEFFAMINE T-5000, 32 parts of JEFFAMINE D-2000, 26 parts of DETDA, 30 parts of conductive mica, 0.5 part of Irganox 1076 and 0.5 part of Tinuvin 328. Than), spraying to form polyurea flexible material, its gel time is 9 seconds. The performance of the product is:

[0055]

Embodiment 3

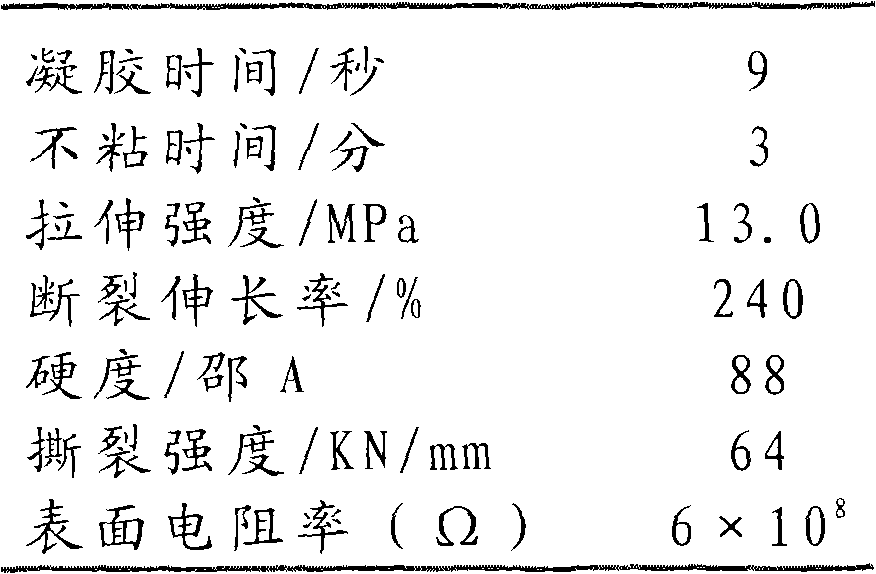

[0057] Synthesize 44 parts of MDI-50, 36 parts of polyether polyol 220, and 20 parts of conductive mica according to the process in this patent to obtain a prepolymer with an NCO% of 13%, which is component A. R component is composed of 10 parts of JEFFAMINE T-5000, 39 parts of JEFFAMINE D-2000, 20 parts of DETDA, 10 parts of conductive carbon black, 20 parts of conductive mica, 0.5 parts of Irganox 1076 and 0.5 parts of Tinuvin 328. A and R components According to 1:1 (volume ratio), the polyurea flexible material is formed by spraying, and its gel time is 9 seconds. The performance of the product is:

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com