High-fluidity and low-viscosity epoxy resin composition and preparation method thereof

An epoxy resin, high fluidity technology, applied in the field of low viscosity epoxy resin composition and its preparation, high fluidity, can solve filling dissatisfaction, line punching, poor balance effect of epoxy molding compound fluidity and viscosity and other problems to achieve the effect of avoiding filling dissatisfaction, improving fluidity and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

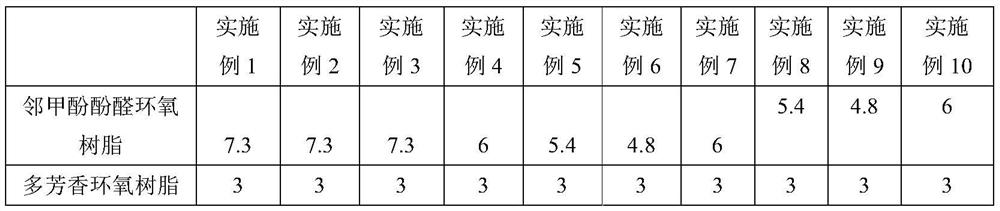

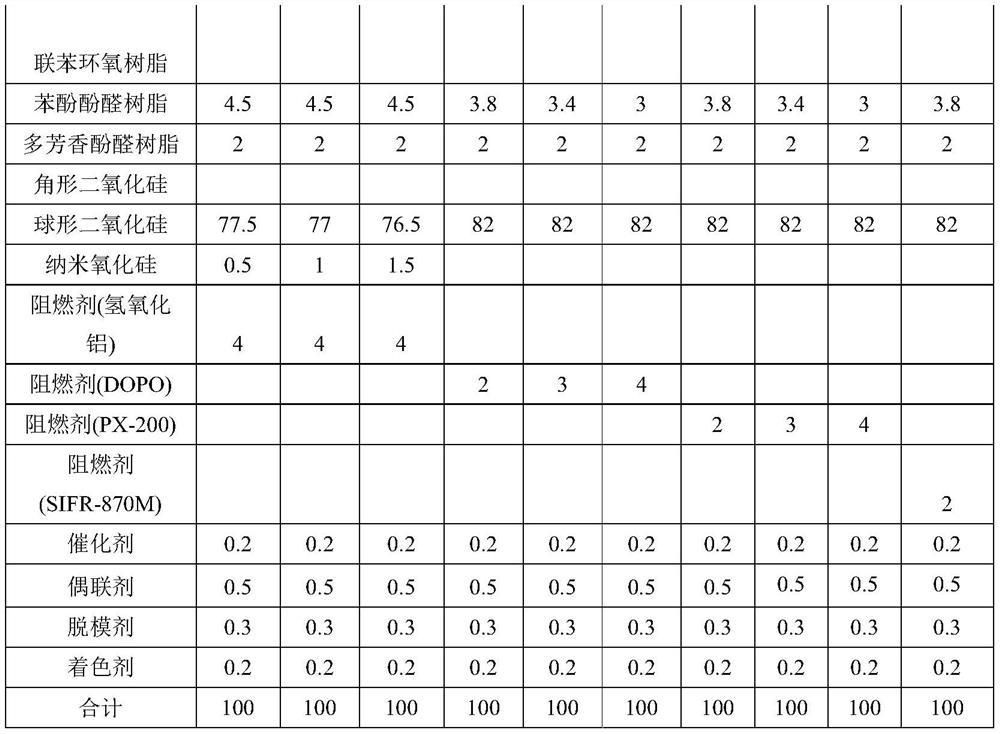

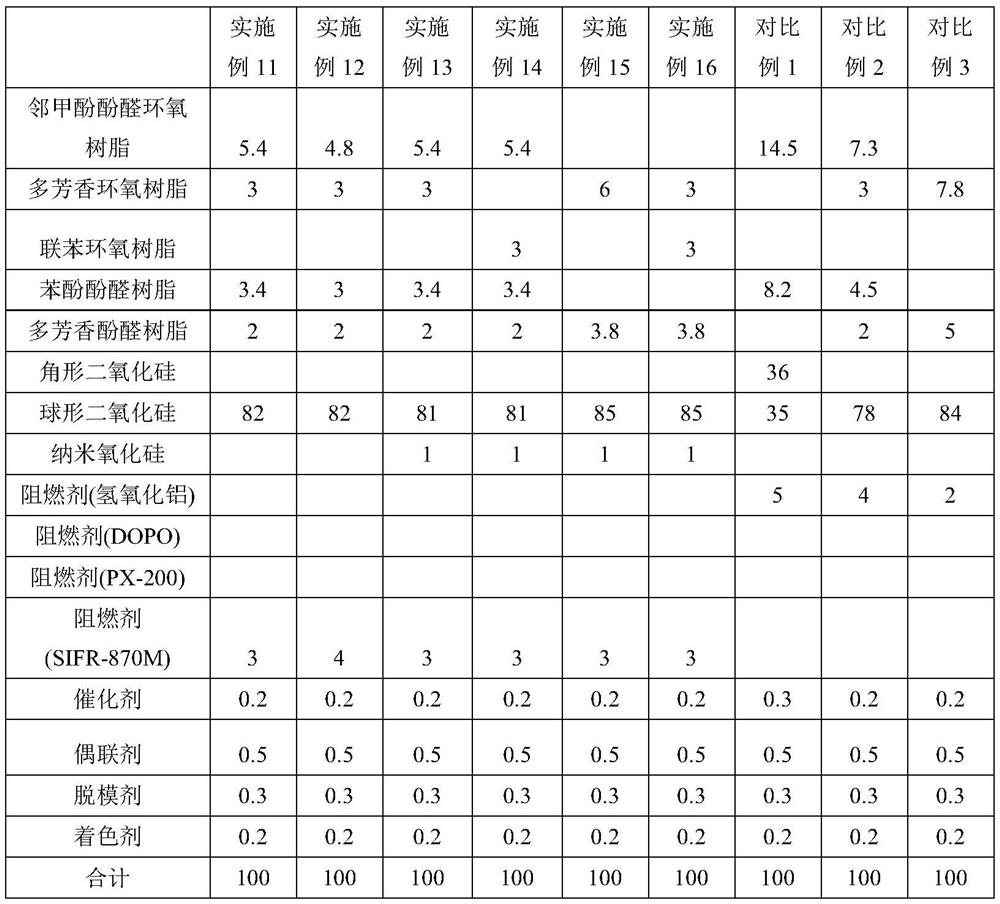

[0059] A high-flowability, low-viscosity epoxy resin composition, the preparation raw materials include: epoxy resin, curing agent, inorganic filler, modifier, flame retardant, catalyst, coupling agent, release agent, coloring agent.

[0060] Described epoxy resin comprises o-cresol novolac epoxy resin, polyaromatic epoxy resin, biphenyl epoxy resin;

[0061] O-cresol novolac epoxy resin, brand name CNE 195 XL-4, purchased from Changchun Artificial Resin Factory Co., Ltd.;

[0062] Polyaromatic epoxy resin, grade NC 3000, purchased from Nippon Kayaku Co., Ltd.;

[0063] Biphenyl epoxy resin, brand YX 4000H, purchased from Japan Mitsubishi Corporation;

[0064] The curing agent includes phenol phenolic resin and polyaromatic phenolic resin.

[0065] Phenol phenolic resin, grade HF-3M, purchased from Japan Meiwa Co., Ltd.;

[0066] Polyaromatic phenolic resin, grade MEH-7851SS, purchased from Japan Meiwa Co., Ltd.;

[0067] Described flame retardant comprises organophosphoru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com