High-temperature-resistant and easy-to-unroll composite expansion adhesive tape, and preparation method and application thereof

A high temperature resistant and unwinding technology, which is applied in the direction of film/sheet adhesives, adhesives, electrical components, etc., can solve the problems of increased lateral shrinkage and folding thickness, inability to fully apply shrinkage, and low temperature resistance of tapes. Achieve the effects of avoiding electrolyte leakage, improving shrinkage resistance, temperature resistance and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

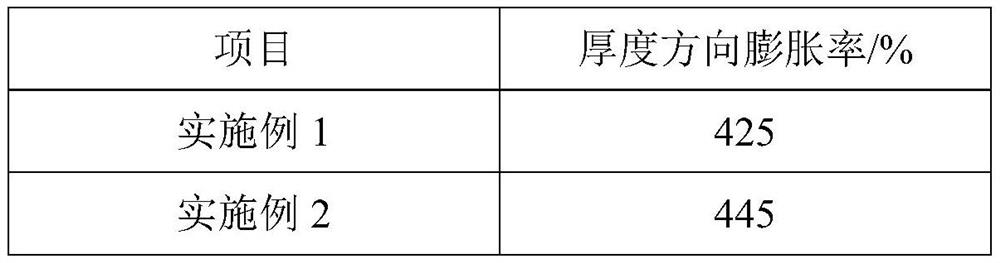

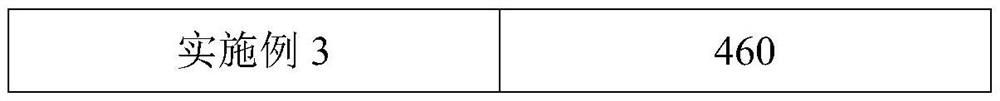

Embodiment 1

[0042] A high-temperature-resistant and easy-to-unwind composite expansion tape, comprising a first adhesive layer (4 μm), a temperature-resistant layer (6 μm), a second adhesive layer (4 μm) and a base layer (40 μm), wherein the base layer is oriented Polystyrene membrane.

[0043] The material of the oriented polystyrene film includes 88% of general-purpose polystyrene (GPPS), 6% of high-impact polystyrene (HIPS), and 2% of nanometer silicon dioxide, calculated by weight percentage. The above material constituting the oriented polystyrene film can be obtained through melt extrusion, extrusion molding, and then transverse and longitudinal stretching; the transverse stretching ratio is 3 to 5 times; the longitudinal stretching ratio is 2 to 3 times.

[0044]The composition of the polyacrylate glue forming the adhesive layer includes: 45% polyacrylate, 0.1% 1,6-isocyanate, and the balance is ethyl solvent.

[0045] The specific preparation steps of the high temperature-resista...

Embodiment 2

[0051] A high-temperature-resistant and easy-to-unwind composite expansion tape, comprising a first adhesive layer (2 μm), a temperature-resistant layer (4 μm), a second adhesive layer (2 μm) and a base layer (50 μm) arranged in sequence, wherein the base layer is oriented Polystyrene membrane.

[0052] The materials of the oriented polystyrene film include 85% of general-purpose polystyrene (GPPS), 5% of high-impact polystyrene (HIPS), and 2.3% of nanometer silicon dioxide, calculated by weight percentage.

[0053] The composition of the adhesive layer glue and the production steps of the adhesive tape are the same as in Example 1.

Embodiment 3

[0055] A high-temperature-resistant and easy-to-unwind composite expansion tape, including a first adhesive layer (6 μm), a temperature-resistant layer (10 μm), a second adhesive layer (6 μm) and a base layer (60 μm) arranged in sequence, wherein the base layer is oriented Polystyrene membrane.

[0056] The material of the oriented polystyrene film includes 90% of general-purpose polystyrene (GPPS), 8% of high-impact polystyrene (HIPS), and 0.9% of nano-silicon dioxide, calculated by weight percentage.

[0057] The composition of the adhesive layer glue and the production steps of the adhesive tape are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com