Thermally stable guar gum aqueous solution and its preparation method and application

A guar gum, aqueous solution technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0058] Preparation Example 1 Preparation of hydroxypropyl guar gum base liquid: Weigh 5.5 g of hydroxypropyl guar gum powder and dissolve it in 1000 ml of tap water, and stir for 15 minutes to fully swell the hydroxypropyl guar gum powder. Weigh 0.6g sodium hydroxide and 1.2g sodium carbonate, add sodium hydroxide and sodium carbonate to the hydroxypropyl guar gum solution respectively, continue to stir for 10min, wait for the guar gum solution to be stable, roughly measure its pH with pH test paper Value, make sure it is around pH=11. Then store the guar gum base solution at 25°C for at least 4 hours for later use.

Embodiment 1

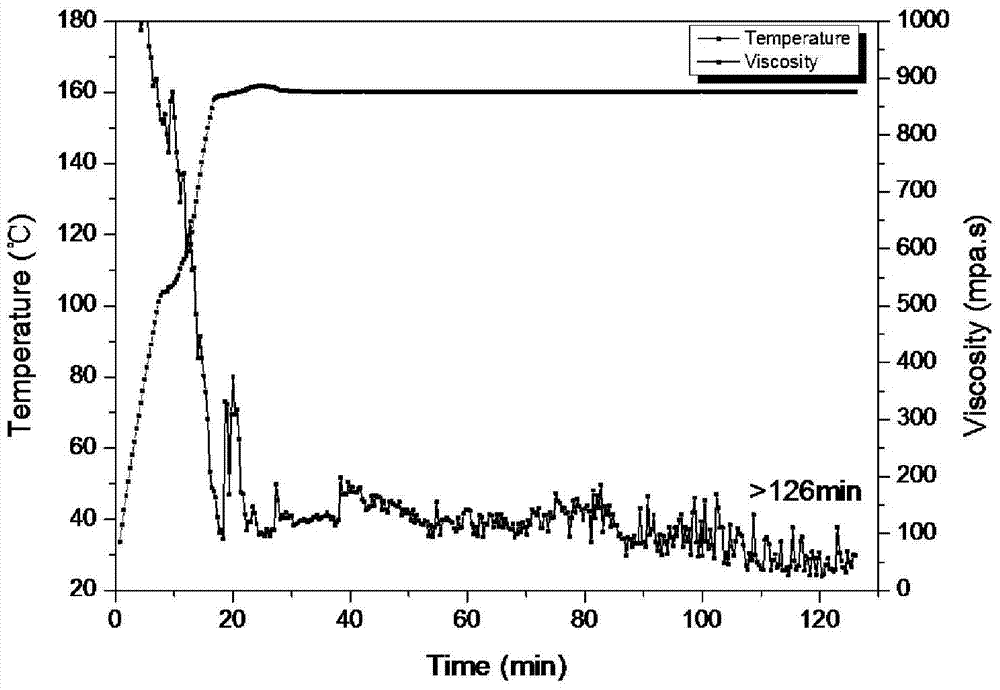

[0059] Example 1 Weigh 0.20 g of sodium gallate, 0.12 g of sodium sulfite, and add 0.5 g of organoboron crosslinking agent BCL-61 into 100 g of the hydroxypropyl guar gum base liquid prepared in Preparation Example 1, and immediately stir in the same direction make it cross-linked. Wait until the mixture is ready to hang. Then the temperature resistance and shear resistance performance test of the obtained aqueous solution (also known as fracturing fluid) was carried out on a HAAKE RheoStress 6000 rheometer (test temperature: heating rate: 10°C / min, constant temperature after heating to 160°C, shear rate : 170S -1 ). The test results show that the viscosity of the fracturing fluid is still stable after being continuously sheared for 100 minutes, and after 126 minutes, the viscosity slightly decreases by about 50 MPa·s (see figure 1 ).

Embodiment 2

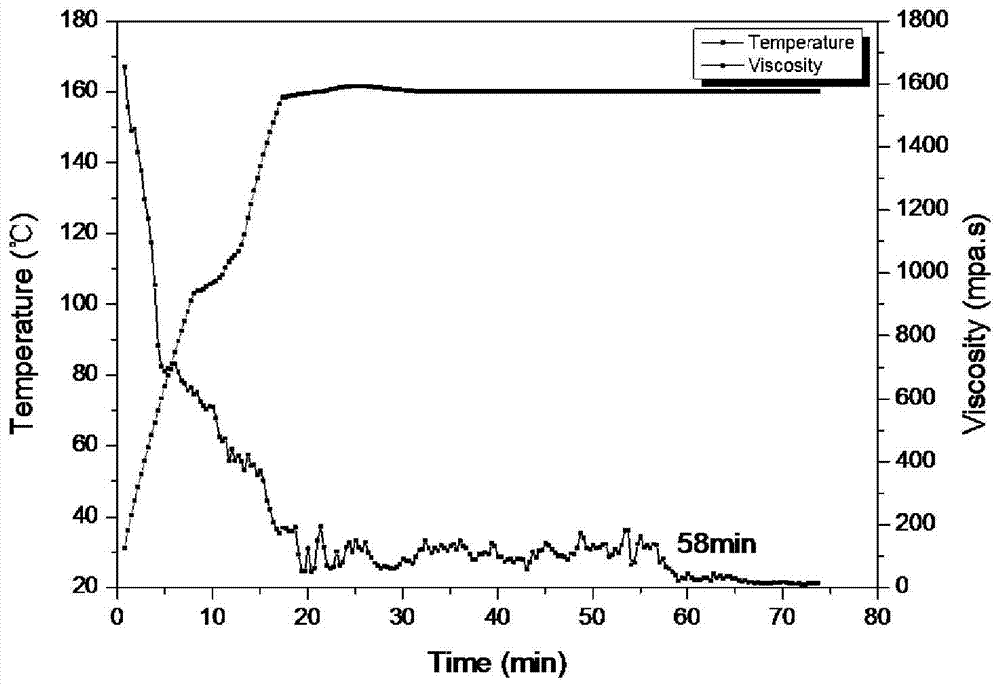

[0066] Example 2 Weigh 0.40g of sodium gallate, 0.24 of sodium sulfite, and 0.5g of organoboron crosslinking agent BCL-61 into 100g of hydroxypropyl guar base liquid, and immediately stir in the same direction to crosslink. Wait until the mixture is ready to hang. Then, the temperature resistance and shear resistance performance test of the obtained aqueous solution (also known as fracturing fluid) was carried out on a HAAKE RheoStress 6000 rheometer (test temperature: heating rate: 10°C / min, constant temperature after heating to 160°C, shear rate: 170S -1 ). The test results show that the fracturing fluid has been continuously sheared for 2 hours and has a viscosity of 120MPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com