A kind of transfer substrate, transfer method and transfer equipment of light-emitting diode

A technology for light-emitting diodes and substrates, which is applied in semiconductor/solid-state device testing/measurement, semiconductor devices, electrical components, etc., and can solve the problems of easily damaged array substrates and difficult to remove Micro-LEDs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Aiming at the problems existing in the prior art that during the Micro-LED transfer process, the abnormally luminous Micro-LED is difficult to remove, and the array substrate is easily damaged by laser cutting, the embodiment of the present invention provides a transfer substrate and a light-emitting diode. Transfer methods and transfer equipment.

[0054] The specific implementations of the transfer substrate, light-emitting diode transfer method and transfer equipment provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The size and shape of each structure in the drawings do not reflect the real scale, but are only intended to schematically illustrate the content of the present invention.

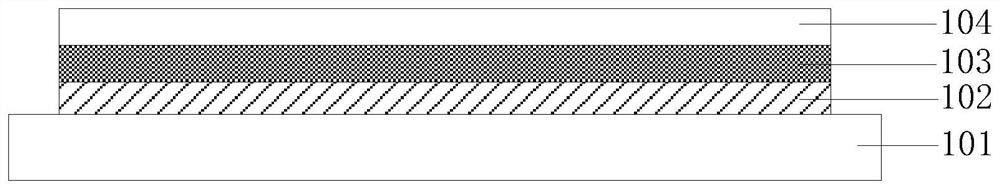

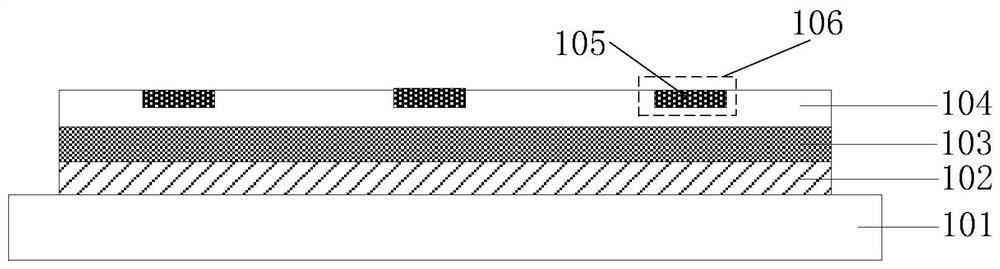

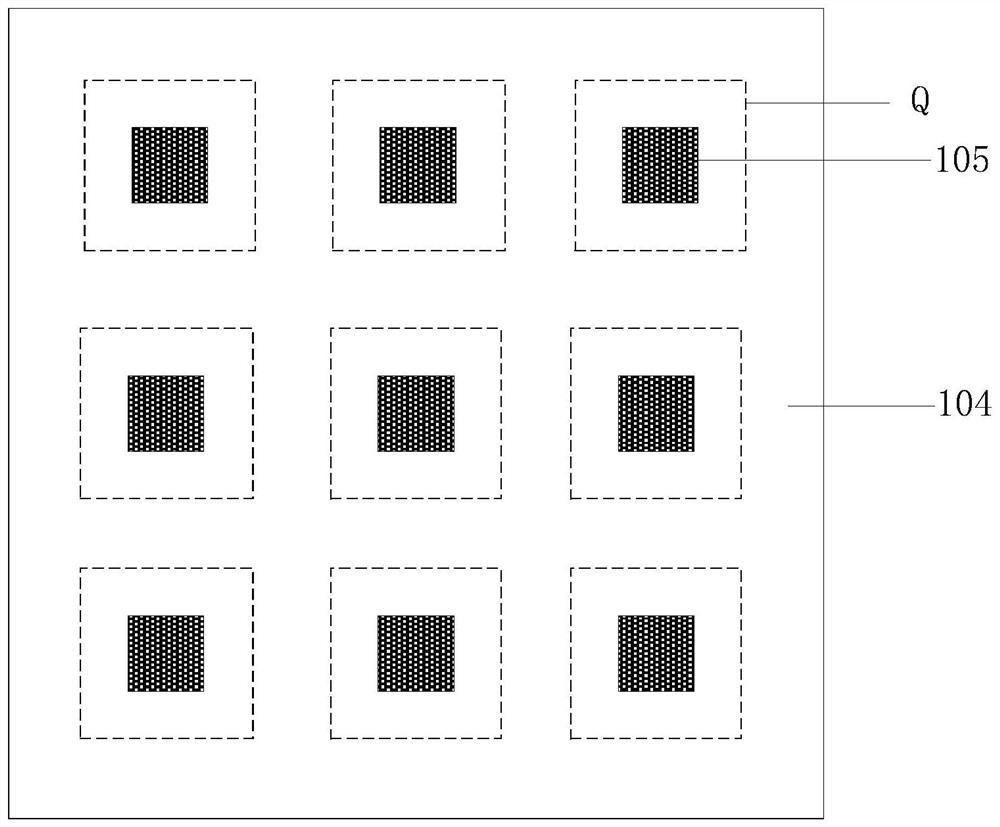

[0055] In the first aspect, the embodiment of the present invention provides a transport substrate, such as figure 1 As shown, it includes: a substrate 101, a reflective layer 102 located on the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com