A heating-improved heat treatment equipment for alloy steel strips and a heat treatment process for alloy steel strips

A heat treatment equipment and improved technology, applied in the direction of heat treatment equipment, heat treatment furnace, process efficiency improvement, etc., can solve the problems of less use, inconvenient use, limited application area, etc., to achieve convenient operation, simple structure, comprehensive strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

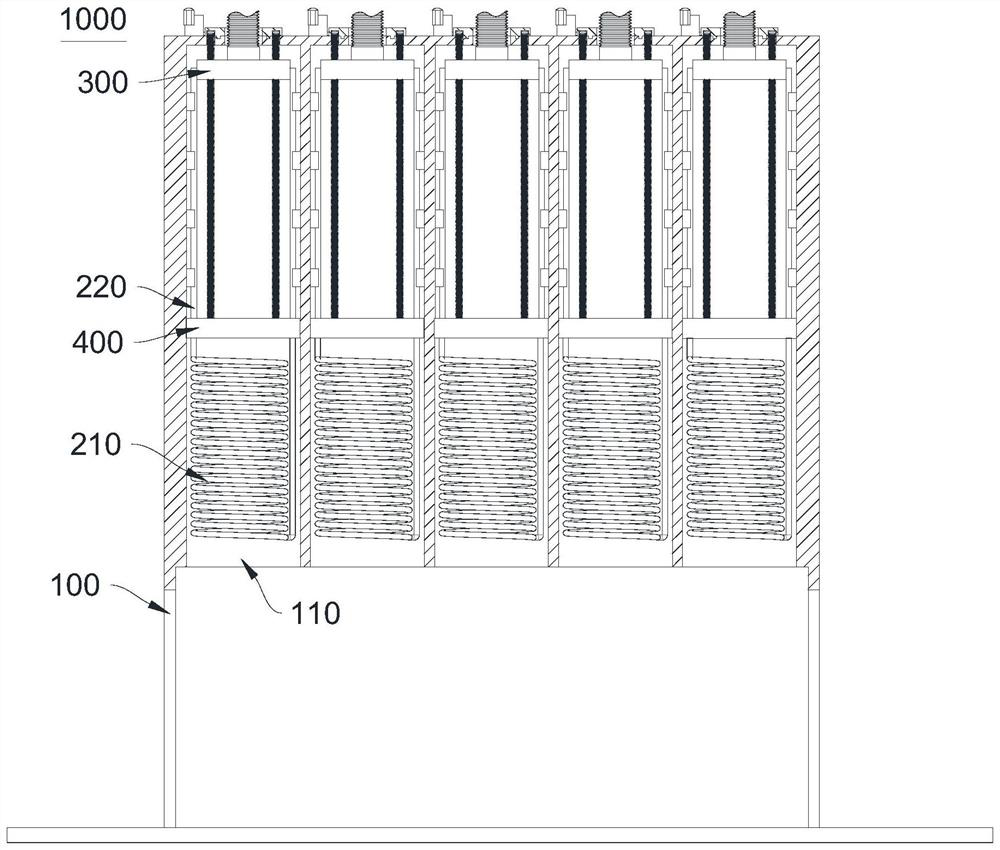

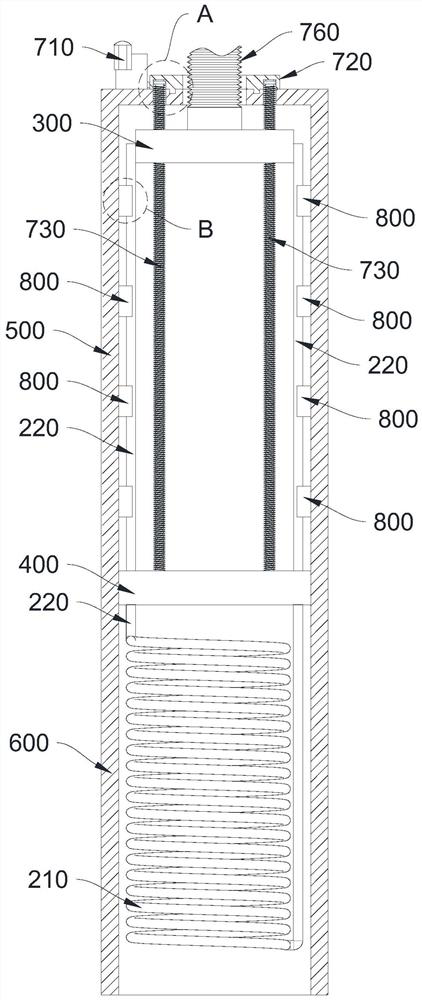

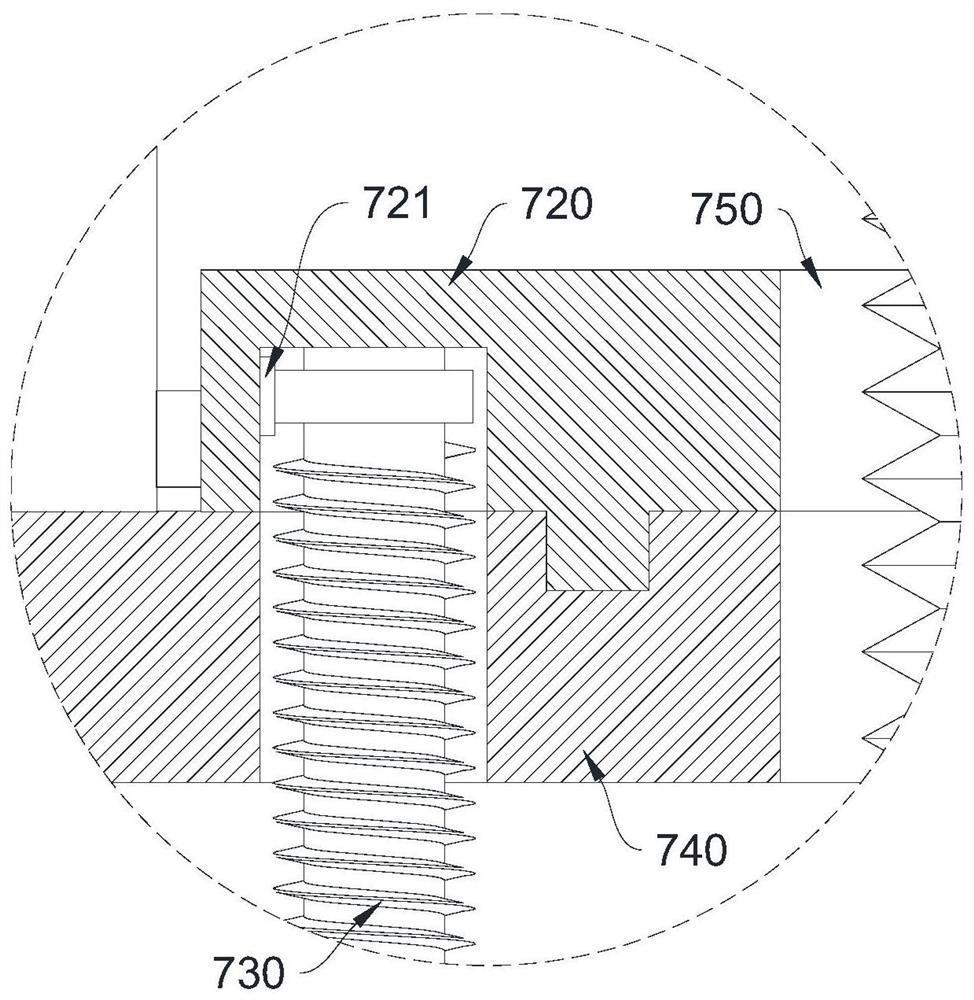

[0046] Please refer to Figure 1~7 , the present embodiment provides a heating-improved heat treatment equipment 1000 for alloy steel strips. The heating-improved heat treatment equipment 1000 includes: a heat treatment chamber 100, an induction coil, a first base 300, a partition 400, and a first guide pipe 500 , the second guide pipe 600 and the first lifting assembly.

[0047] The first guide tube 500 and the second guide tube 600 are coaxially arranged and connected, and the partition plate 400 is fixedly installed on the connecting portion of the first guide tube 500 and the second guide tube 600 to completely separate the two. The seat 300 is disposed on the first guide tube 500 .

[0048] The induction coil includes a coil body 210 and an extension section 220 , the extension section 220 is made of conductive material and connected to the terminal of the coil body 210 . The coil body 210 is accommodated in the second guide tube 600 , and the extension section 220 pene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com