Heat pipe and refrigerating system combined energy transportation method

A refrigeration system and composite technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of large occupied space, complex system, large energy consumption, etc. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

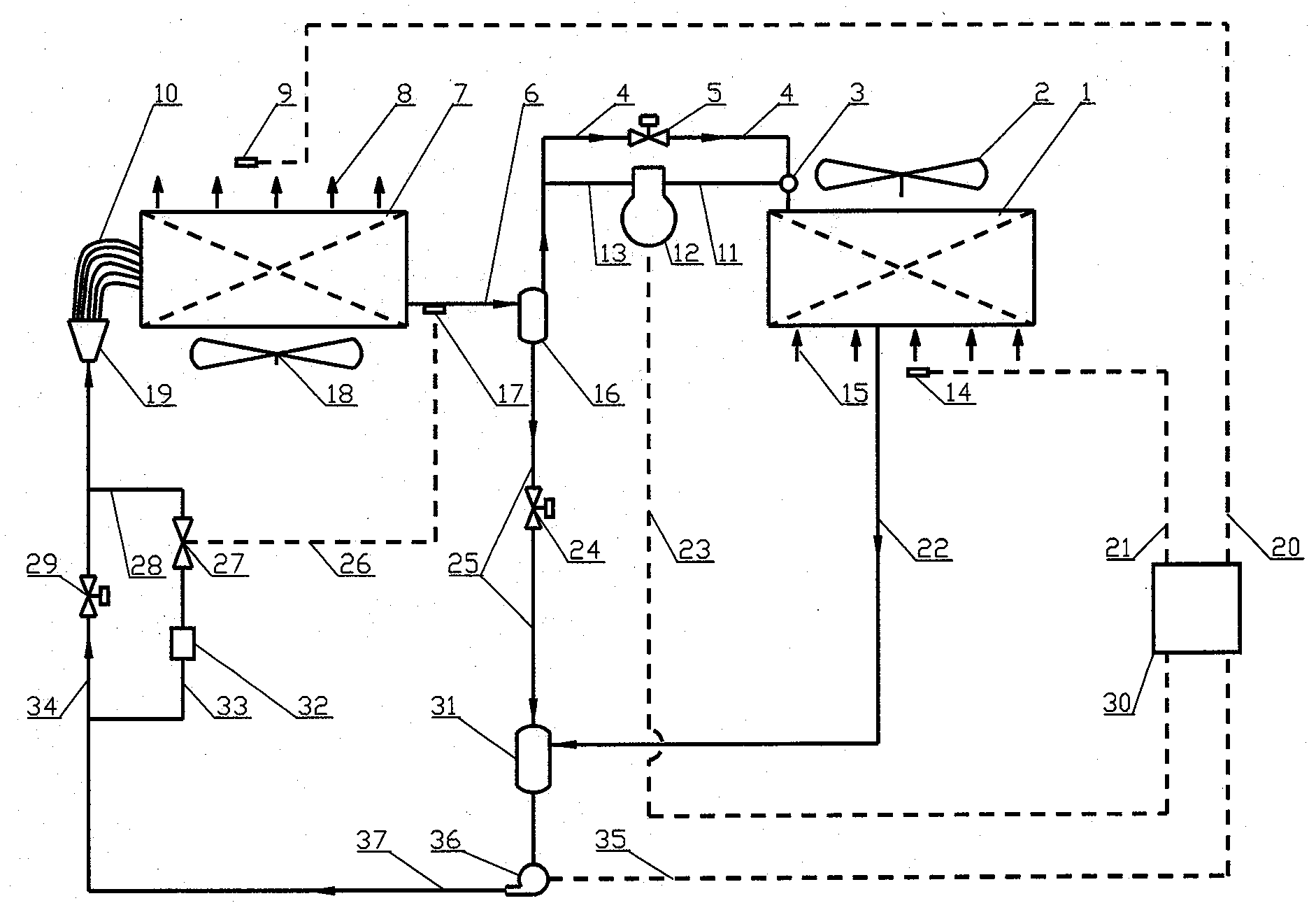

[0033] This embodiment is the workflow of the first kind of energy transportation, as attached figure 1As shown, the direction of the circulation arrow in the figure is the flow direction of the heat pipe working medium; evaporator 7, gas-liquid separator 16, condenser 1, liquid storage tank 31, solution circulation pump 36, liquid separator 19, equal length liquid equalizer Tube 10, working condition switching solenoid valves 5, 24, 29, interconnecting pipelines, temperature adjustment and control parts, etc. are organically connected to form a double-cycle controllable heat pipe system; under the working condition of the heat pipe, the working condition switching solenoid valve 5, 24, 29 are in the open state, and a relatively independent The working fluid circulates (the small cycle in the double cycle); while the gas-phase working medium enters the uniform gas distribution pipe 3 through the gas pipeline 4, the gas-phase working medium switching solenoid valve 5, and the g...

Embodiment 2

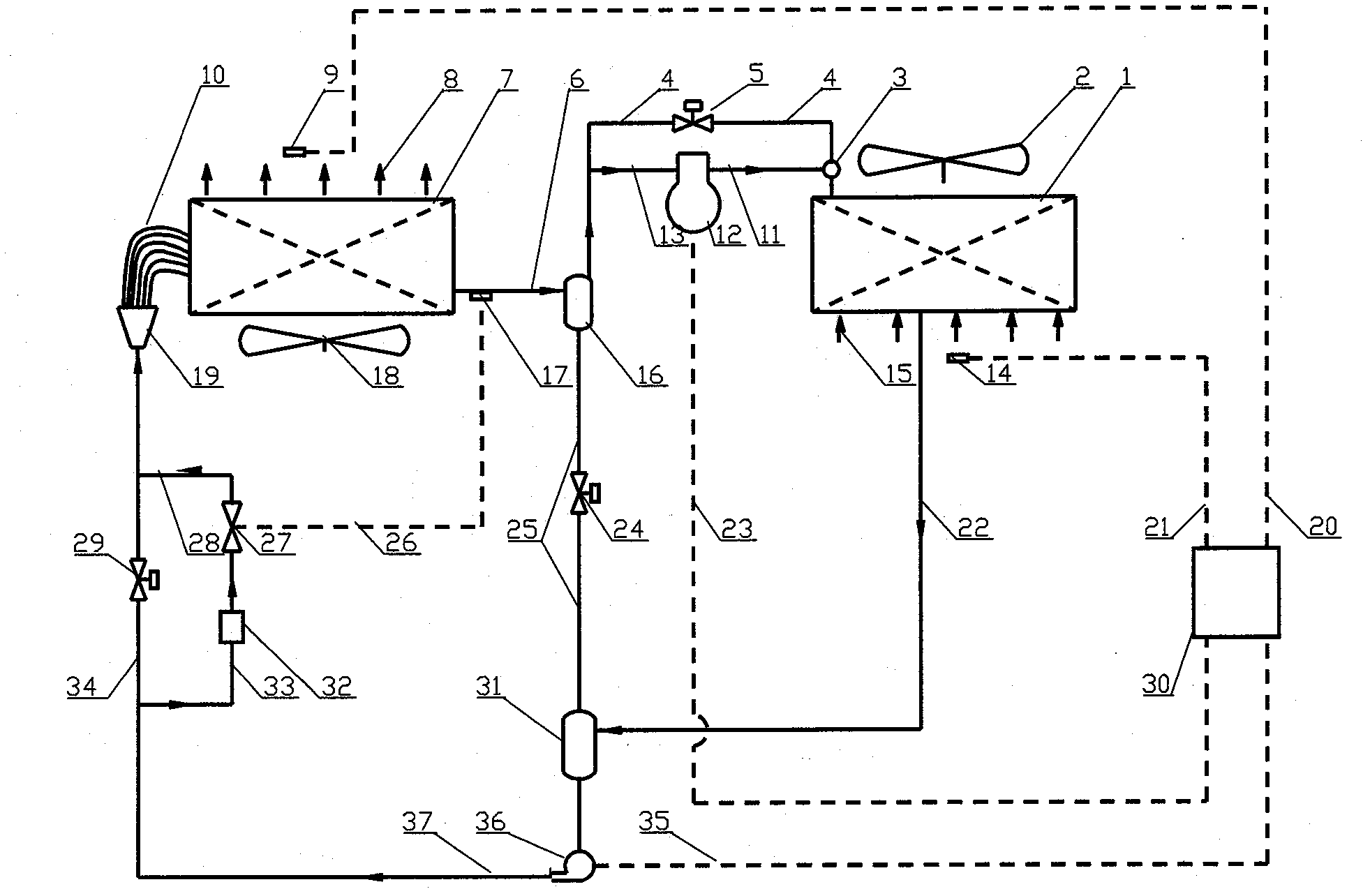

[0034] Embodiment 2: attached image 3 It is the working flow diagram of the second scheme of the present embodiment, except that the throttling parts composed of the throttle valve 27, the temperature signal line 26 for the throttle valve and the temperature sensing package 17 for the throttle valve are replaced with the throttle capillary 38, Other parts are the same as Embodiment 1. This embodiment is especially suitable for small systems, and has the advantages of simple structure and low cost; its start-up and operation process are the same as Embodiment 1.

Embodiment 3

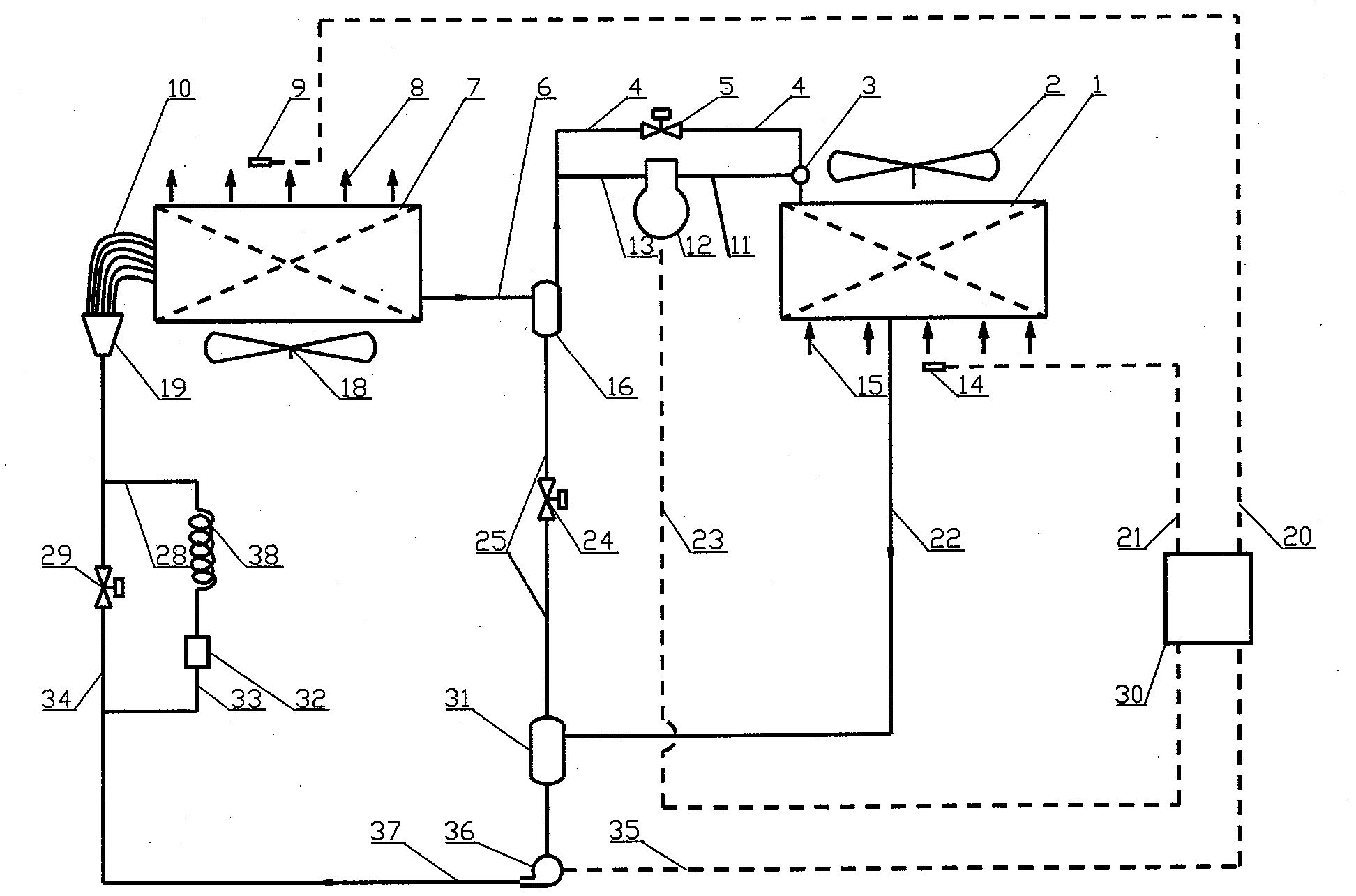

[0035] Embodiment 3: Attach Figure 4 It is the working flow diagram of the third scheme of this embodiment, except that the gas-liquid separator 16 is replaced with the gas-liquid separation main pipe 39, the other parts are the same as in the embodiment 1, and the characteristic is that the evaporator and the gas-liquid separator are organically combined, The structure is compact; its start-up and operation process are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com