Selective sintering-machine flue-gas heat exchange and denitration system and method thereof

A flue gas heat exchange and sintering machine technology, applied in the field of flue gas denitrification, to achieve the effect of superior NOx emission, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

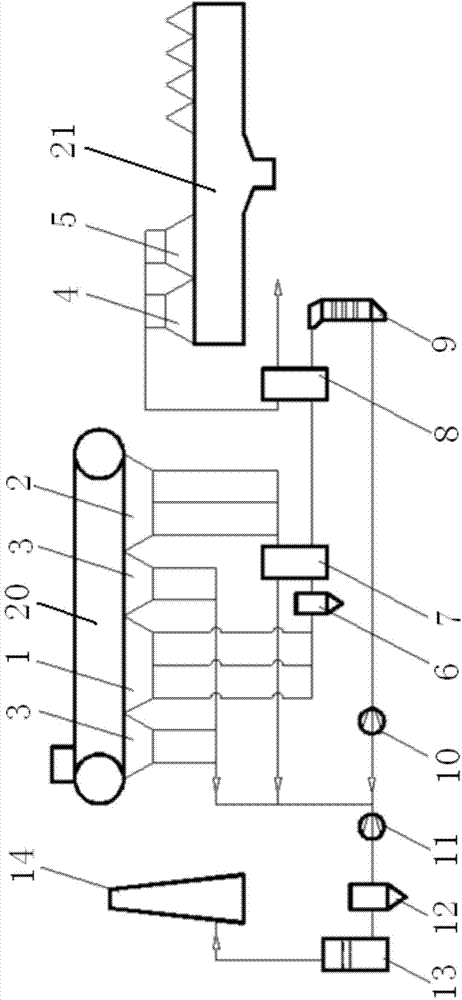

[0022] The selective sintering machine flue gas heat exchange and denitrification system according to the present invention will be further described in detail below in conjunction with the accompanying drawings. A selective sintering machine flue gas heat exchange and denitrification system, comprising a sintering machine 20, a primary heat exchanger 7, a denitrification device 9, a main dust collector 12 and a desulfurization device 13, and the high nitrogen oxide wind box 1 of the sintering machine 20 is connected with the The primary heat exchanger 7, the denitration device 9, the main dust remover 12 and the desulfurization device 13 are connected, and the high temperature wind box 2 of the sintering machine 20 is connected with the main dust remover 12 after passing through the primary heat exchanger 7, as figure 1 As shown, the desulfurization device 13 is an SCR denitrification device.

[0023] During the sintering process, the sintering machine produces a large amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com