Vortex heating pressure adjuster

A heating type and pressure regulator technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., to achieve the effects of low energy consumption, simple manufacturing, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

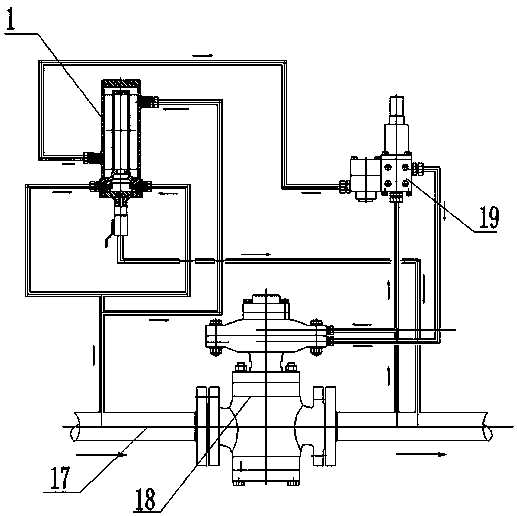

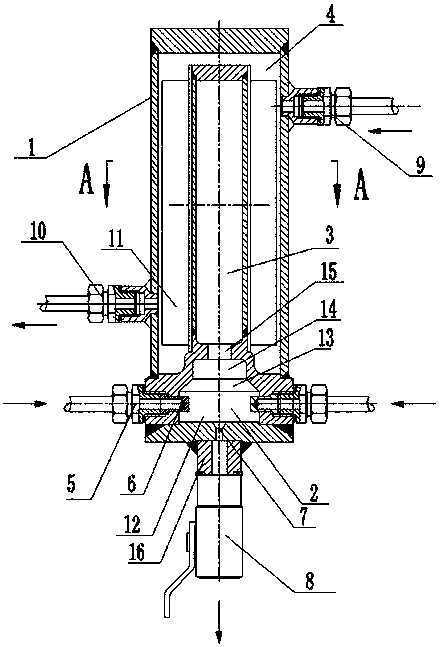

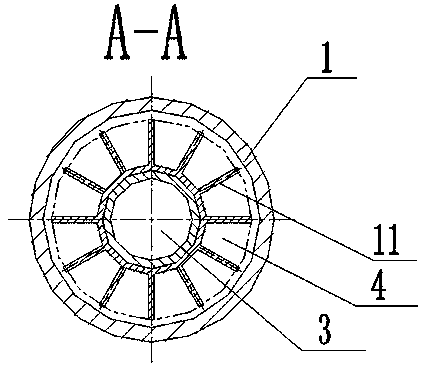

[0030] As a preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

[0031]The vortex heating type pressure regulator includes the main adjustment part 18 and the pilot 19, the pilot 19 is connected with the main adjustment part 18 through the connecting pipeline, and also includes a heater, the heater includes a heater body 1, and the heater body 1 is provided with an air inlet chamber 2, a heating chamber 3 and a heat exchange chamber 4, the air inlet chamber 2 communicates with the heating chamber 3, the air inlet chamber 2 is provided with an air inlet 5, and the air inlet 5 The pipeline communicates with the inlet end of the gas pipe network 17, and the gas at the inlet end of the gas pipe network 17 enters the air intake cavity 2 through the air inlet 5; The gas is injected into the intake cavity 2 along the tangential direction of the inner wall of the intake cavity 2, and the gas intake cavity 2 is also prov...

Embodiment 2

[0033] As another preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

[0034] The vortex heating type pressure regulator includes the main adjustment part 18 and the pilot 19, the pilot 19 is connected with the main adjustment part 18 through the connecting pipeline, and also includes a heater, the heater includes a heater body 1, and the heater body 1 is provided with an air inlet chamber 2, a heating chamber 3 and a heat exchange chamber 4, the air inlet chamber 2 communicates with the heating chamber 3, the air inlet chamber 2 is provided with an air inlet 5, and the air inlet 5 The pipeline communicates with the inlet end of the gas pipe network 17, and the gas at the inlet end of the gas pipe network 17 enters the air intake cavity 2 through the air inlet 5; The gas is injected into the intake cavity 2 along the tangential direction of the inner wall of the intake cavity 2, and the gas intake cavity 2 is al...

Embodiment 3

[0038] As another preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

[0039] The vortex heating type pressure regulator includes the main adjustment part 18 and the pilot 19, the pilot 19 is connected with the main adjustment part 18 through the connecting pipeline, and also includes a heater, the heater includes a heater body 1, and the heater body 1 is provided with an air inlet chamber 2, a heating chamber 3 and a heat exchange chamber 4, the air inlet chamber 2 communicates with the heating chamber 3, the air inlet chamber 2 is provided with an air inlet 5, and the air inlet 5 The pipeline communicates with the inlet end of the gas pipe network 17, and the gas at the inlet end of the gas pipe network 17 enters the air intake cavity 2 through the air inlet 5; The gas is injected into the intake cavity 2 along the tangential direction of the inner wall of the intake cavity 2, and the intake cavity 2 is also p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com