Drainer with heat recovery function

A technology of heat recovery and function, applied in water supply installations, indoor sanitary piping installations, buildings, etc., can solve problems such as impurity and dirt cleaning, and achieve the effects of eliminating air pollution, sufficient heat absorption, and high heat absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

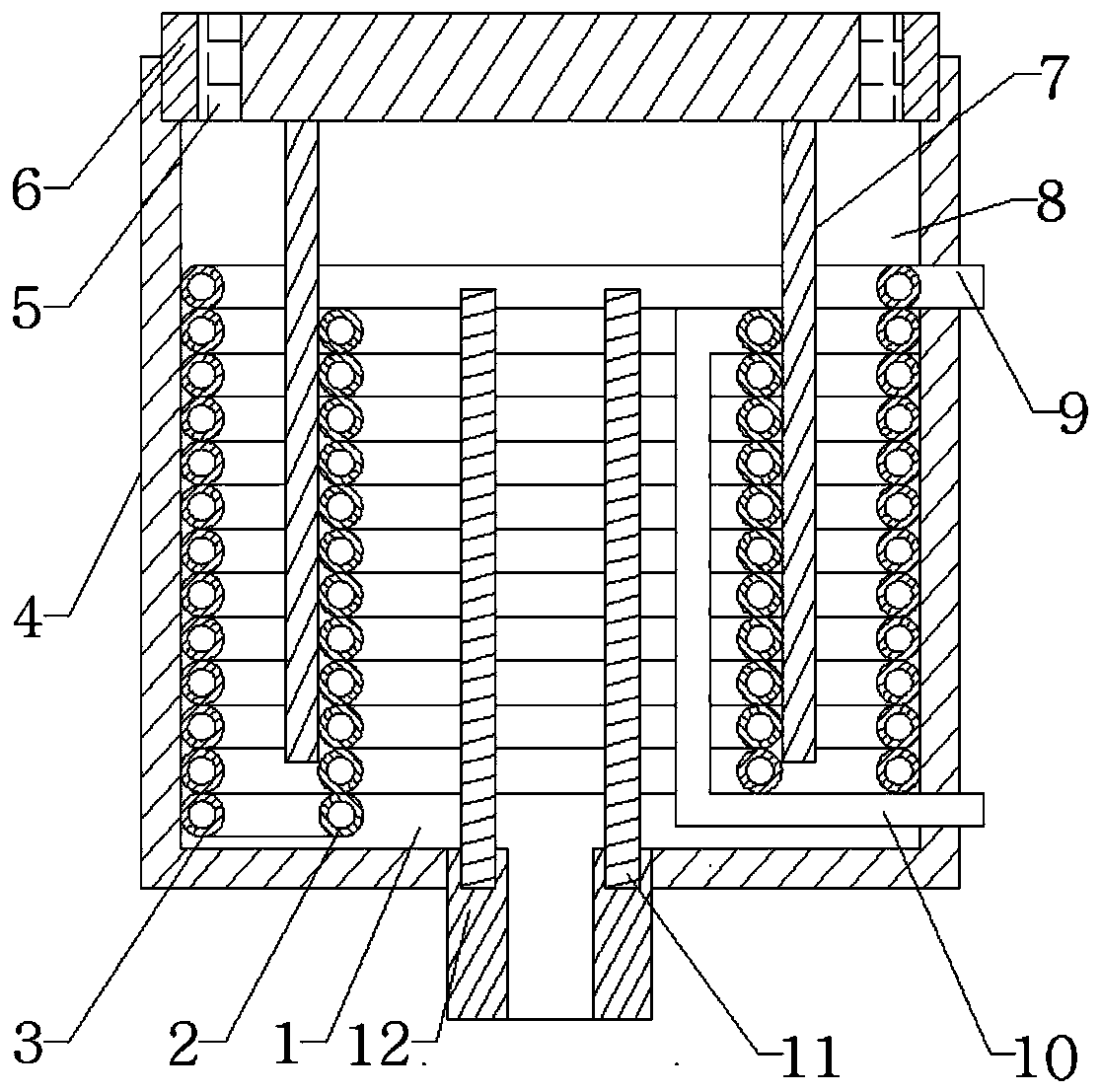

[0017] Embodiment 1: as figure 1 , a drainer with heat recovery function, comprising an outer cylinder 4, the top of the outer cylinder 4 is fastened with a cylinder cover 6, the cylinder cover 6 is coaxially welded with an isolation tube 7, and the isolation tube 7 separates the inner space of the outer cylinder 4 from the From the outside to the inside, it is divided into an outer water tank 8 and an inner water tank 1 in turn. The edge of the cylinder cover 6 is provided with an annular waste water inlet connected to the outer water tank 8. The waste water inlet is also welded with a filter screen 5. The outer water tank 8 is provided with a The first coil 3, the top of the right side of the first coil 3 is welded and communicated with the water inlet pipe 9, the inner tank 1 is provided with the second coil 2 communicating with the first coil 3, the right side of the second coil 2 The top is welded and communicated with a water outlet pipe 10 protruding out of the outer cy...

Embodiment 2

[0023] Embodiment 2: The difference between embodiment 2 and embodiment 1 is only that the drain pipe 11 is coaxially rotated and connected with a connecting pipe (not shown in the figure), the bottom of the drain pipe 11 is provided with a first drainage hole, and the connecting pipe is provided with a A second drain hole communicating with the first drain hole. When no waste water flows into the outer water tank 8 and the inner water tank 1 from the outside, the waste water in the outer water tank 8 and the inner water tank 1 is in a static state. In order to prevent impurities and dirt in the waste water from adhering to the outer cylinder 4 and the first coil 3 and the second coil pipe 2. Therefore, by rotating the connecting pipe, the second drain hole communicates with the first drain hole, and waste water is discharged into the sewage outlet 12 through the first drain hole and the second drain hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com