Device for detecting and adjusting gaps on two sides of rotating body in closed or semi-closed cavity

A technology of adjusting device and rotating body, applied in mechanical clearance measurement, transmission parts, belt/chain/gear, etc., can solve the problems of reducing mechanical efficiency, high cost, leakage, etc. Gap removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

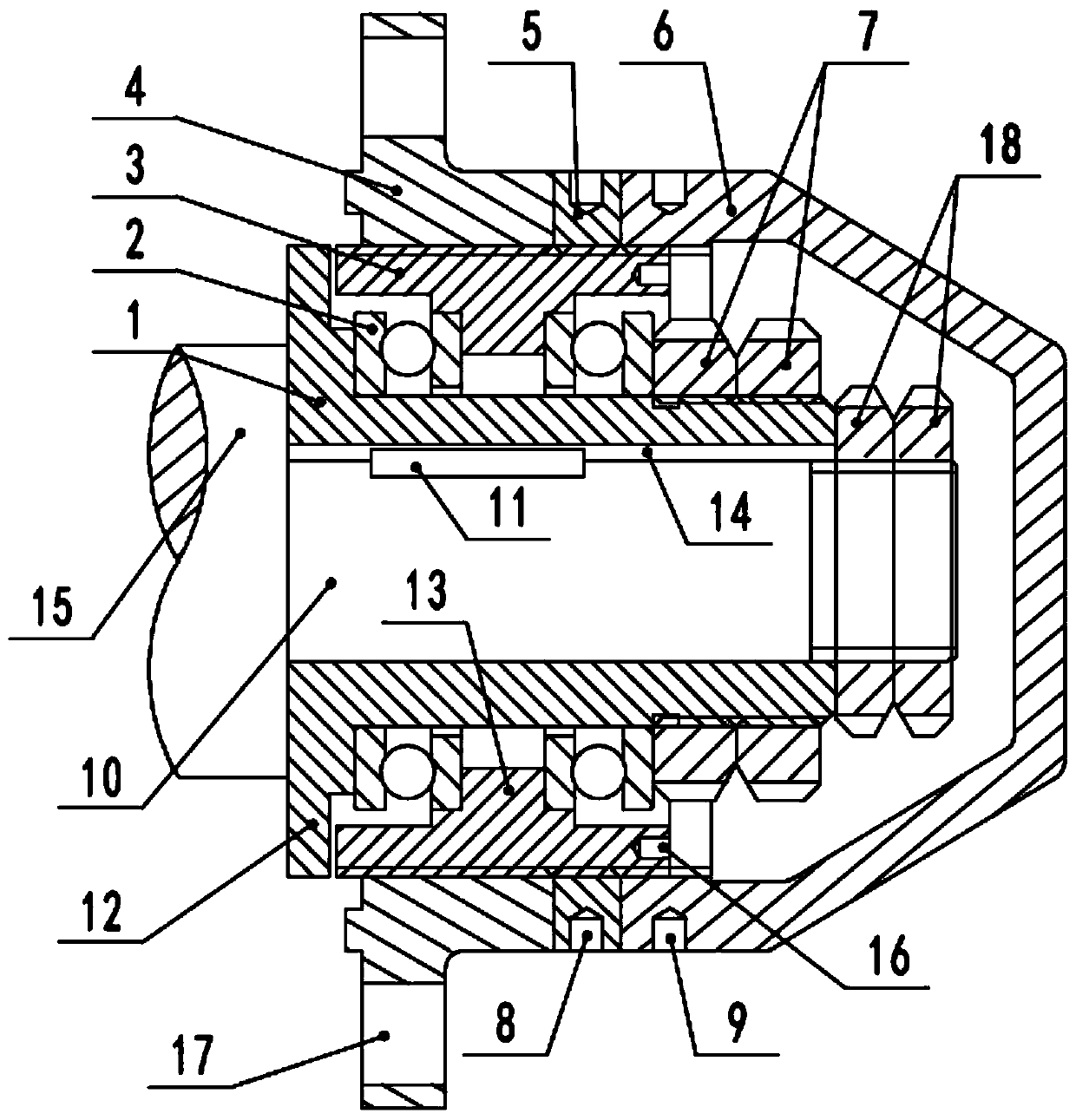

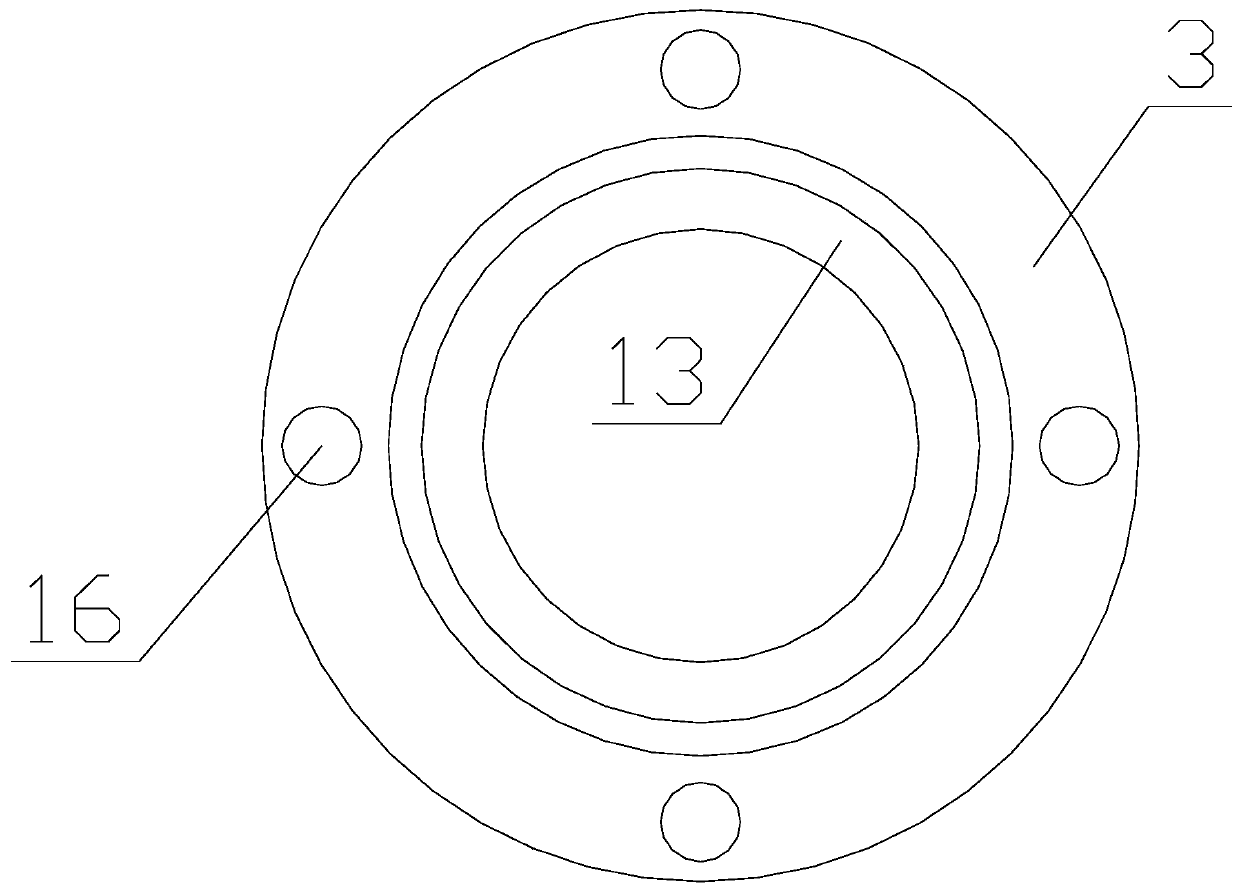

[0030] Such as figure 1 and 2 As shown, the gap detection and adjustment device on both sides of the rotating body in a closed or semi-closed cavity includes a connecting sleeve 1, a bearing 2, an adjusting seat 3 and a connecting seat 4, and the connecting sleeve 1 is coaxially set on the rotating body. One end of the body shaft 10, the connecting shaft sleeve 1 can follow the rotating body shaft 10 to rotate around the central axis of the rotating body shaft 10, the bearing 2 is sleeved on the outer periphery of the connecting shaft sleeve 1, the connecting The seat 4 is fixedly connected to the box for placing the rotating body shaft 10, the connecting seat 4 and the adjusting seat 3 are ring-shaped, and the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com