Manual engagement and disengagement mechanism of electric actuator

A technology of electric actuator and clutch mechanism, applied in the direction of engine components, mechanical equipment, valve operation/release devices, etc., can solve the problems of difficult movement, difficult to manually operate the actuator, and inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

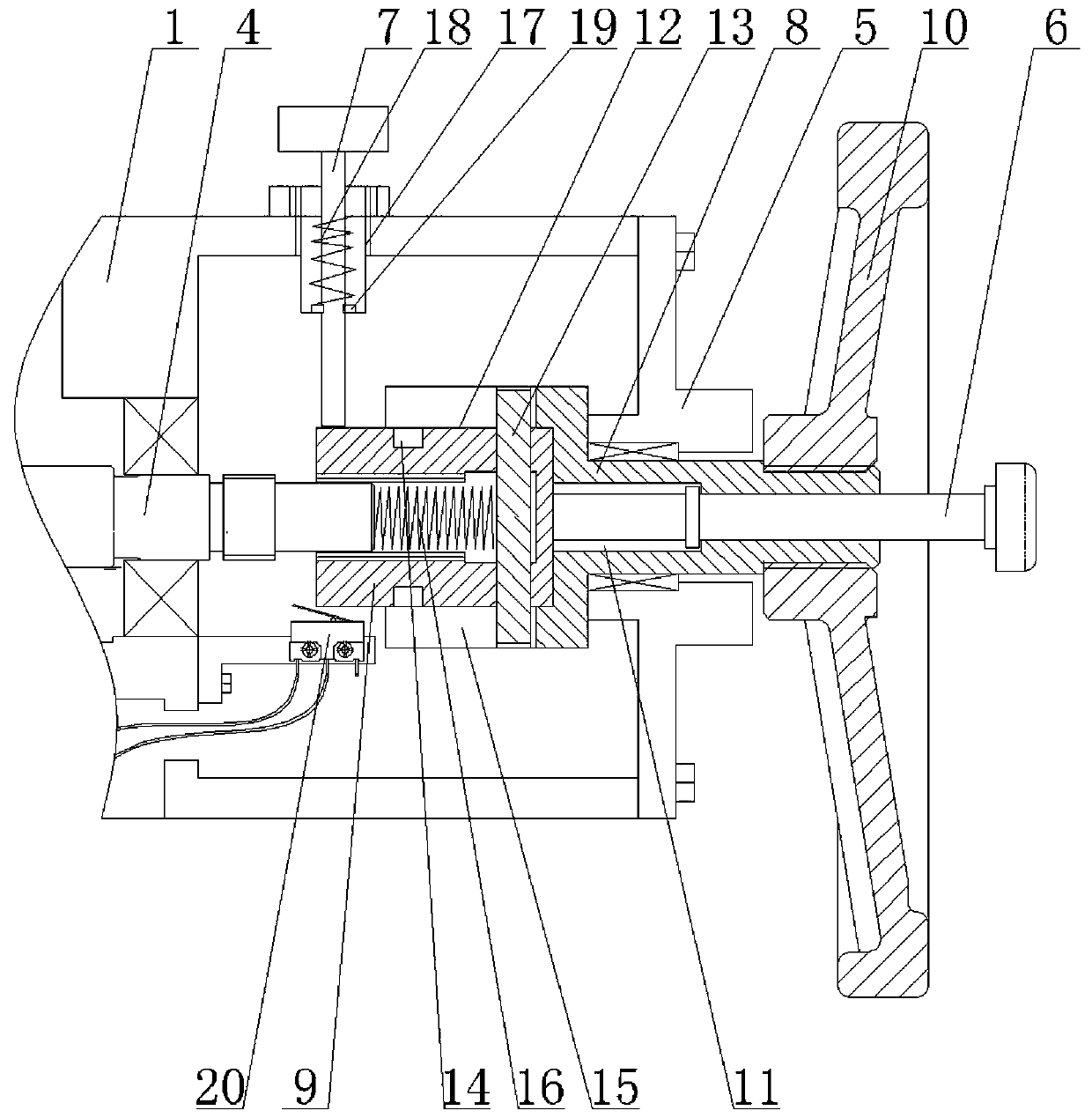

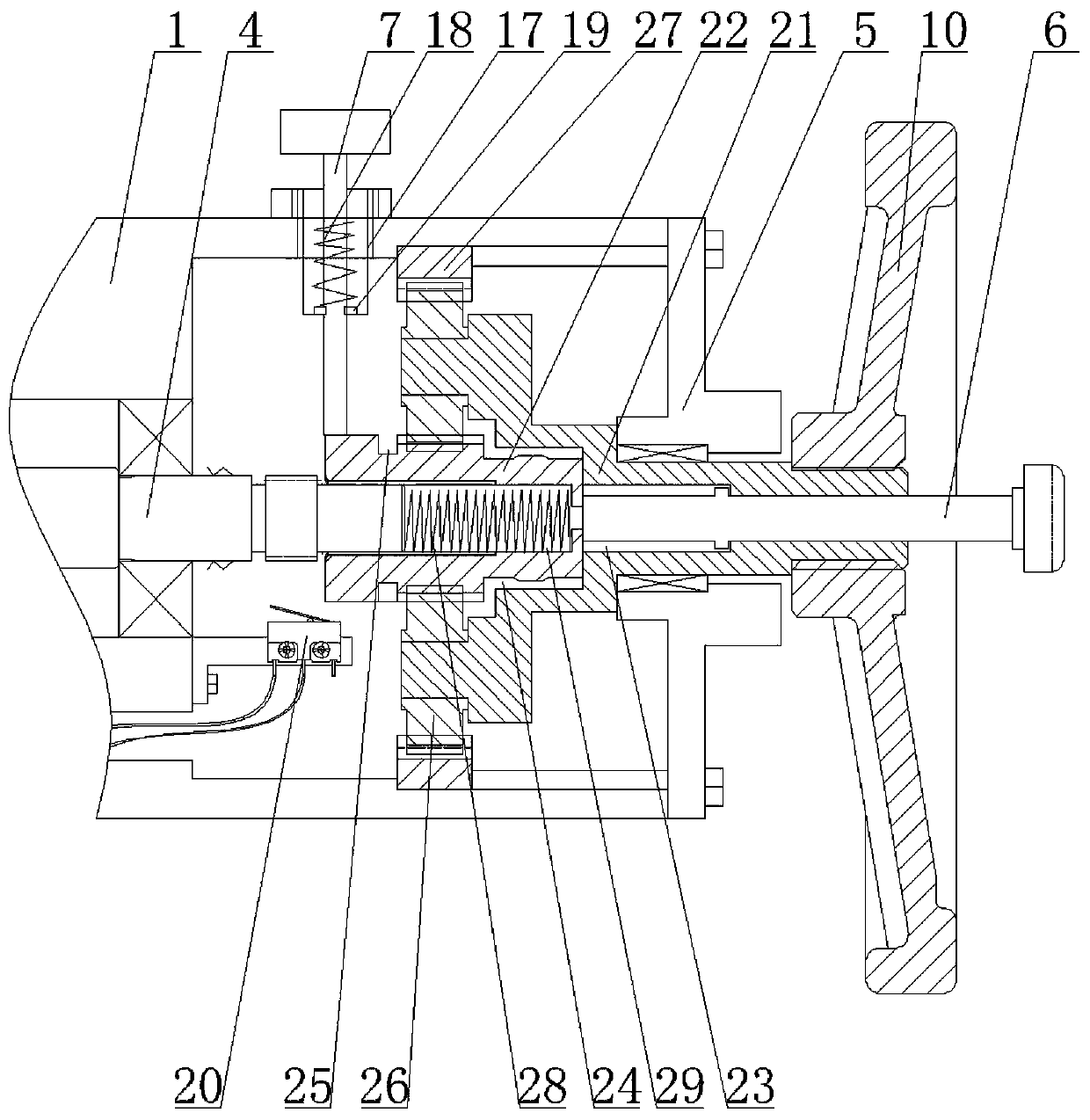

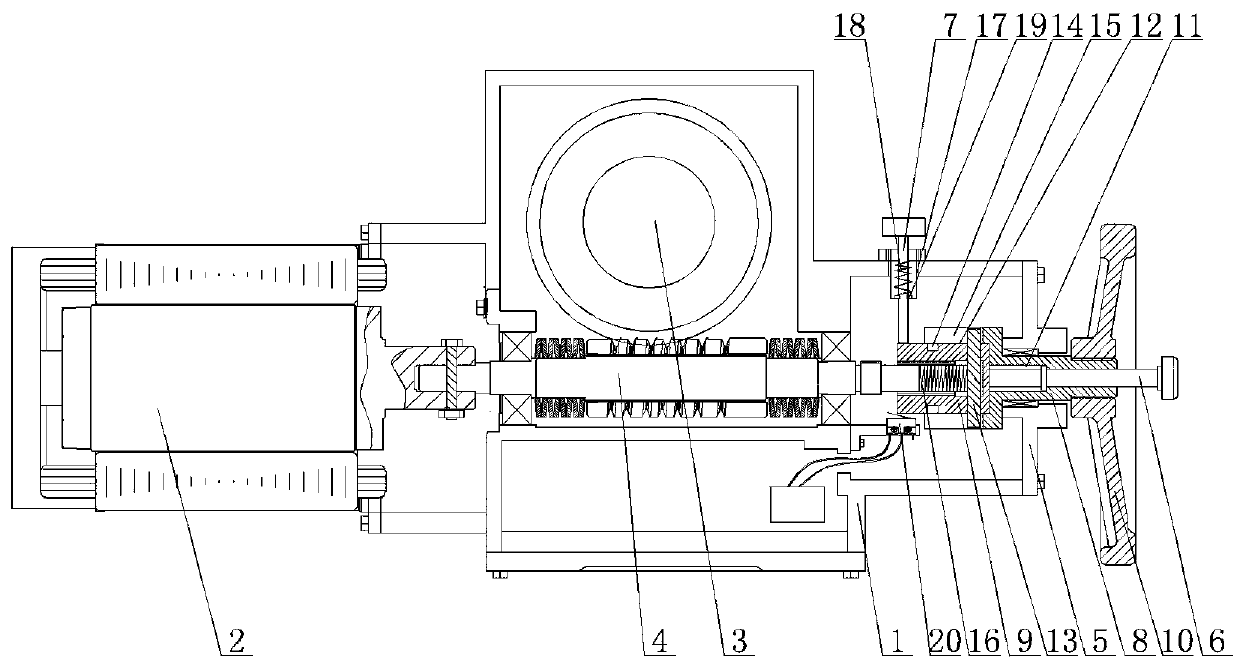

[0016] refer to figure 1 and image 3 As shown, the first embodiment of the manual clutch mechanism of an electric actuator provided by the present invention belongs to the direct-drive manual clutch mode, including a box body 1 and a motor 2 arranged in the box body 1, and mutually meshed The worm gear 3 and the worm 4, the other side of the box body 1 is detachably provided with a hand wheel 10 end cover 5 through bolts, one end of the worm 4 is connected to the rotating shaft of the motor 2, the motor 2 is connected to a power supply, and the end cover 5 of the hand wheel 10 is movable There is a push rod 6, and the inner side of the push rod 6 can drive the worm 4 to rotate through the linkage device. The pull pin 7 that can be inserted into the linkage device is movable on the box body 1. The pull pin 7 is equipped with a reset device. The linkage device includes a handwheel shaft 8 and The inner spline sleeve 9, the handwheel shaft 8 is rotated and installed on the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com