U-shaped tube heat exchanger with baffle plate with air bag structure

A technology of baffles and U-shaped tubes, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., and can solve the problem of reduced service life of U-shaped tube heat exchangers, affecting heat exchange efficiency, and fluid short circuits and other problems, to achieve the effect of eliminating fluid short circuit, improving heat exchange efficiency and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

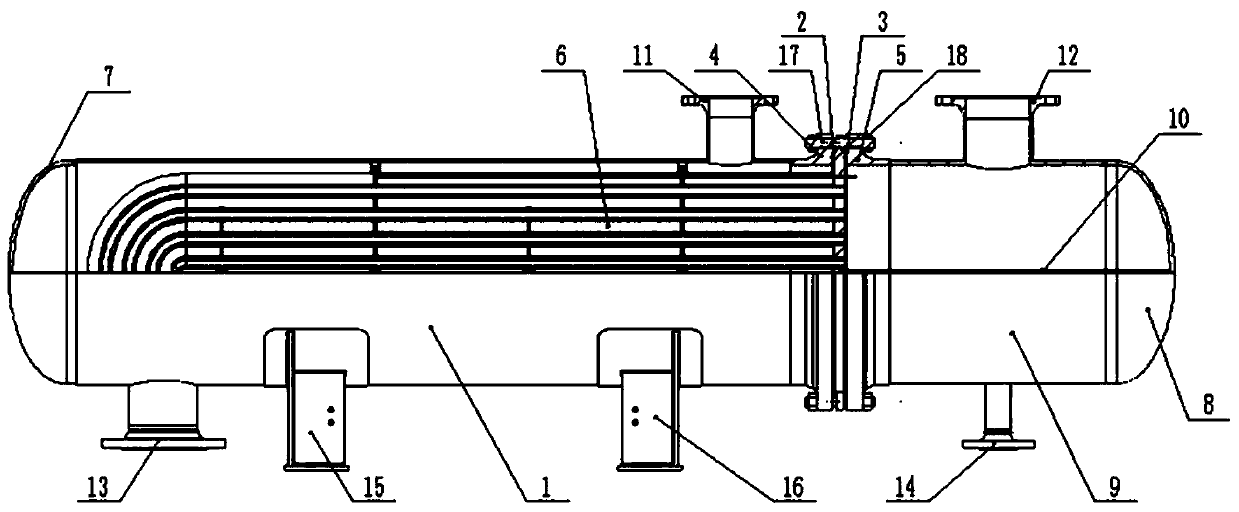

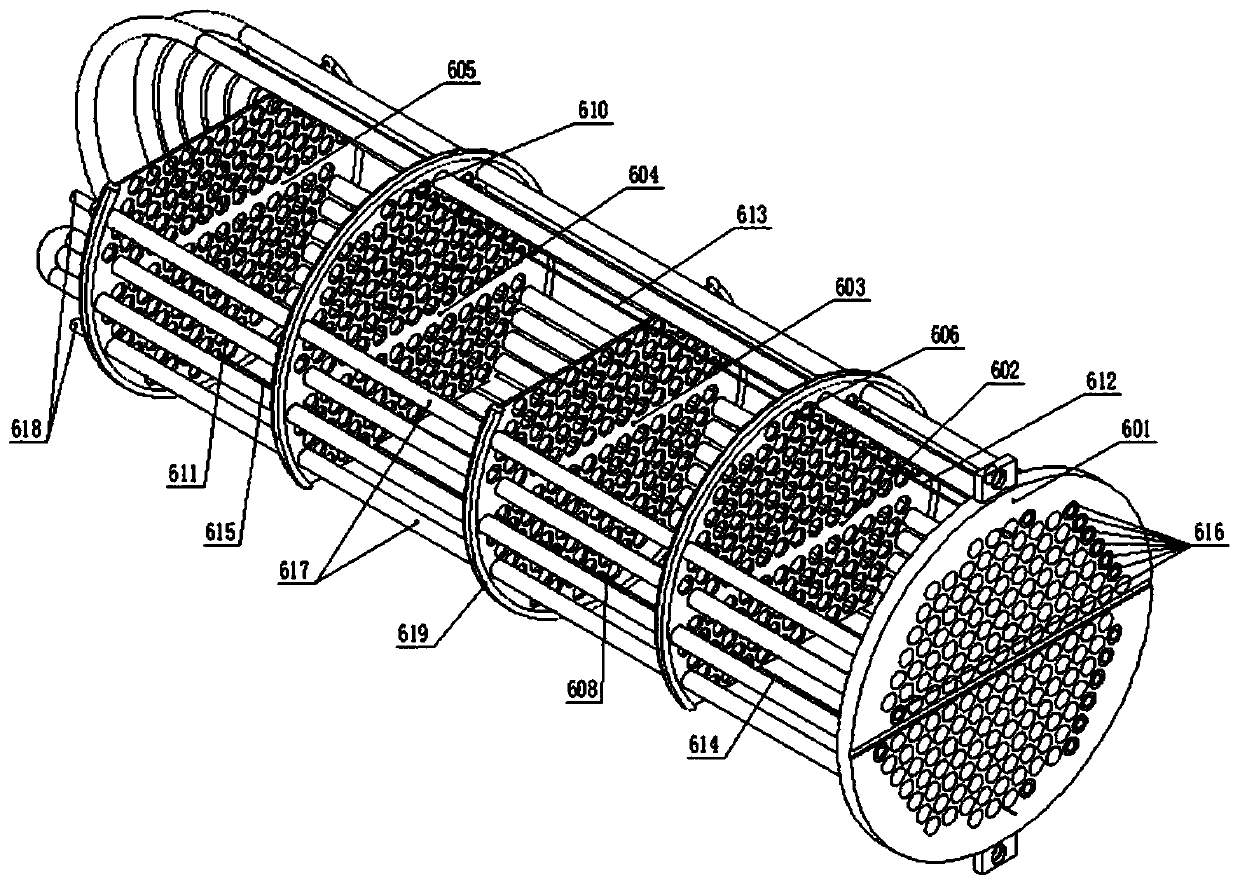

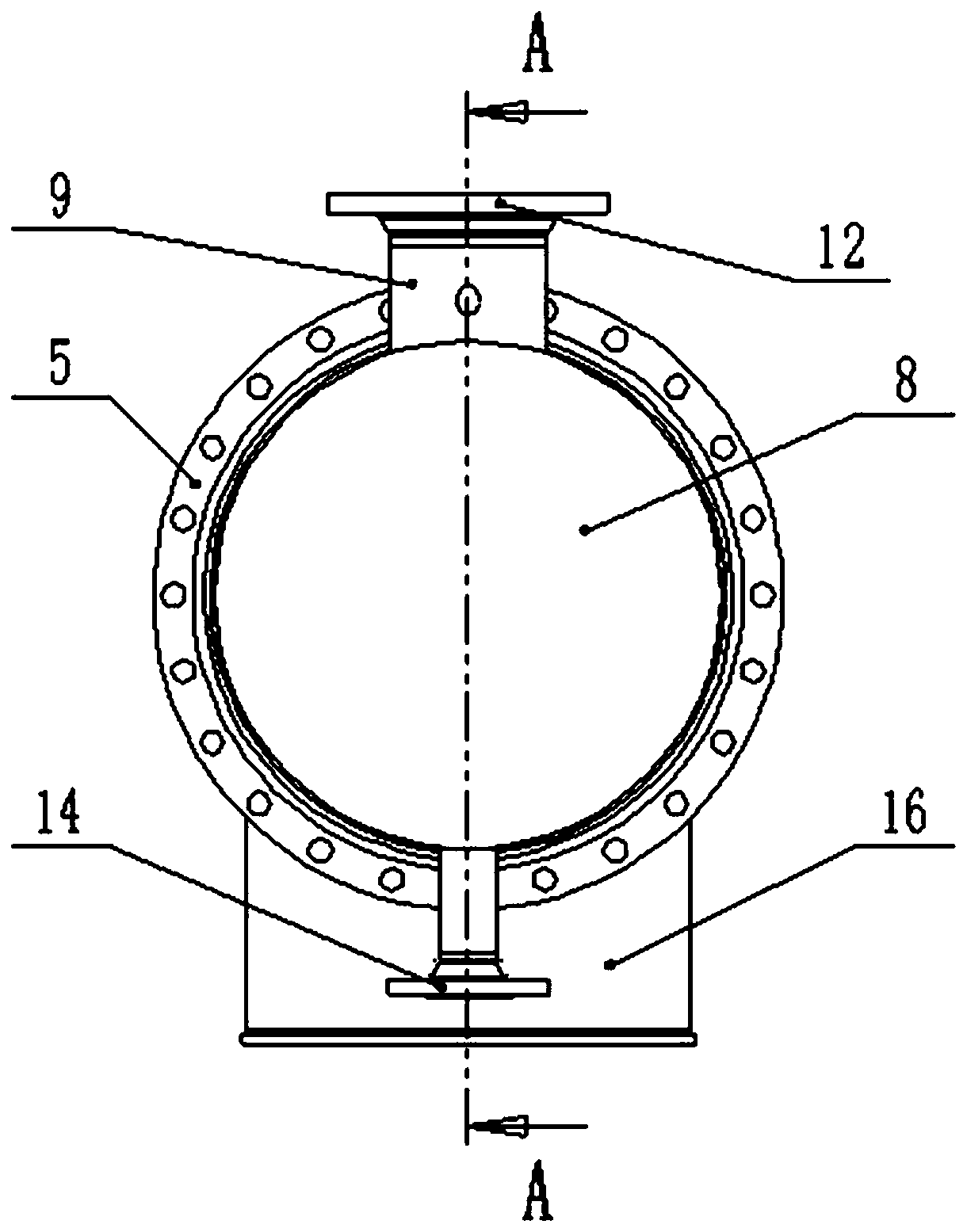

[0029] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0030] Such as Figure 1-Figure 9As shown, the baffle in this embodiment is a single bow baffle, a U-shaped tube heat exchanger with a baffle and an airbag structure, including a cylinder 1, a shell flange gasket a 2, a shell method Lan gasket b 3, shell flange a 4, shell flange b5, tube sheet assembly 6, elliptical head a 7, elliptical head b 8, pipe box cylinder 9, splitter plate 10, belt neck Butt welding flange a 11, neck butt welding flange b 12, neck butt welding flange c 13, neck butt welding flange d 14, saddle support a 15, saddle support b 16, equal length Stud 17, hex nut 18, tube sheet assembly 6 consists of tube sheet 601, baffle a 602, baffle b 603, baffle c604, baffle d 605, connecting plug a 606, connecting plug b 607, connecting plug c 608, connecting plug d 609, connecting plug e 610, connecting plug f 611, air duct a 612, air duct b 613, air duct c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com