Cold-heat source system flow testing device

A system flow and testing device technology, applied in measuring devices, measuring heat, and detecting fluid flow with electromagnetic flowmeters, etc., can solve the problems that flow monitoring and related analysis are not perfect and accurate, and it is difficult to meet the stability of the production process, etc., to achieve Low price, reduce manpower consumption, and realize the effect of long-distance concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

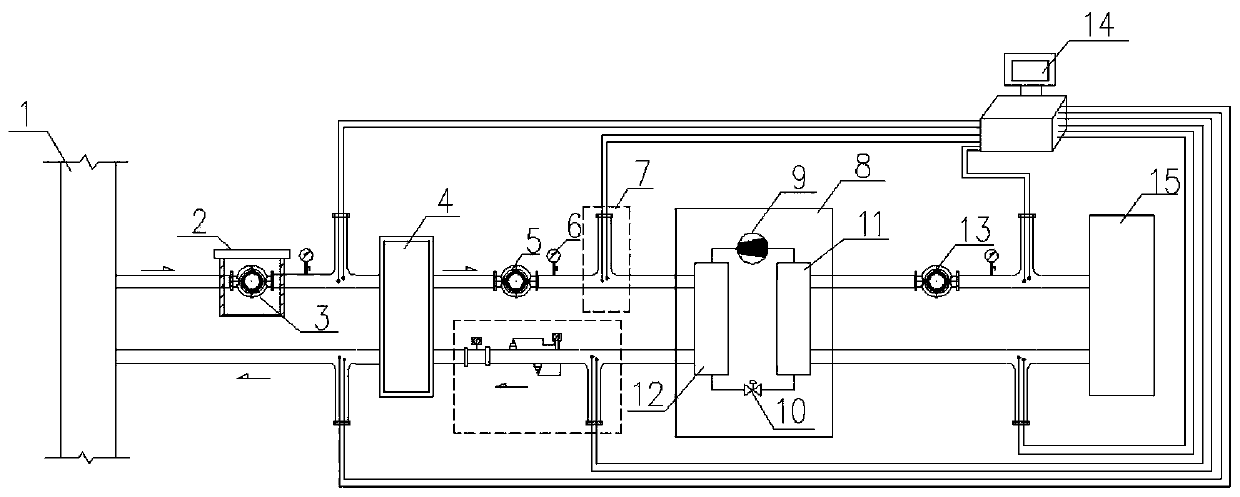

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

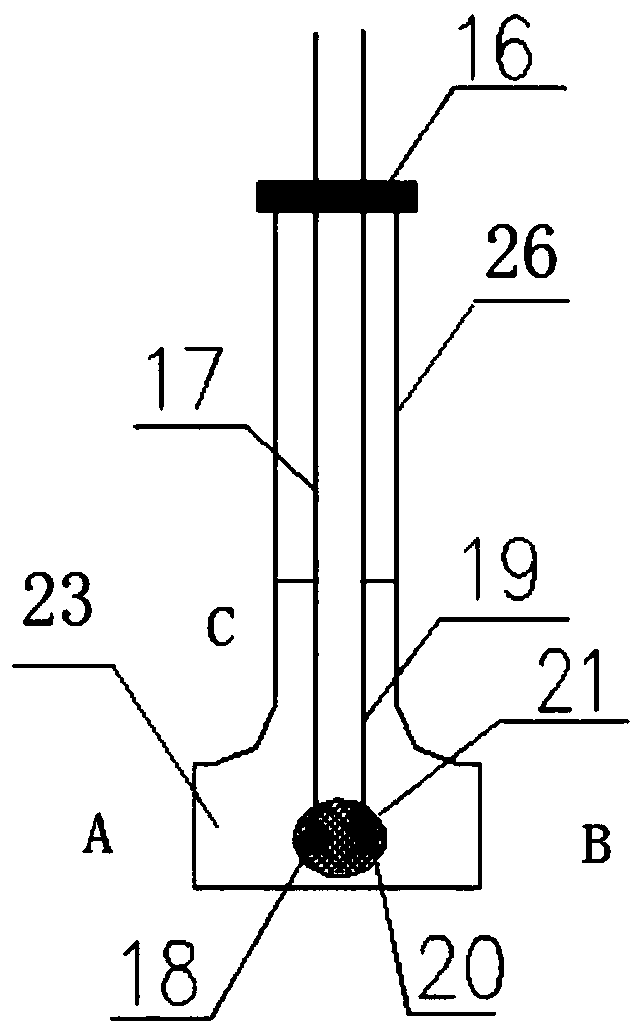

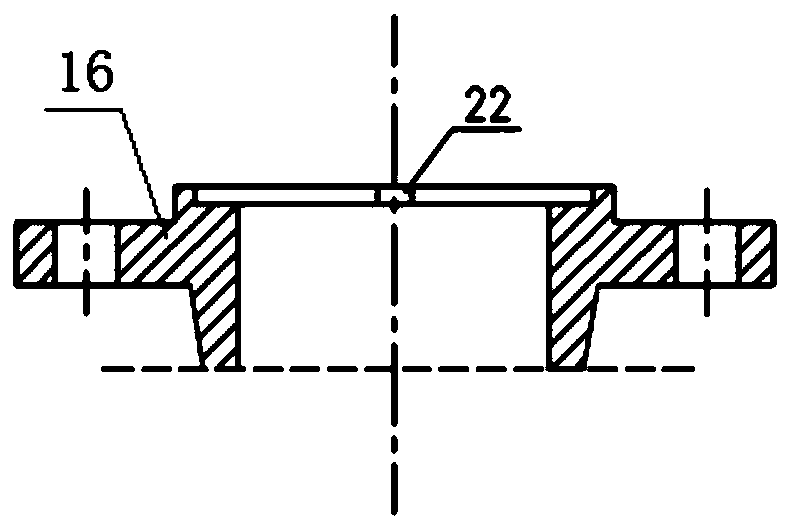

[0021] Such as figure 1 and figure 2 As shown, the flow test device of the cold and heat source system of the present invention includes a tee 23, the A port of the tee 23 is used as the water inlet, the B port is used as the water outlet, and the A port and the B port are on a straight line. The C port of 23 is connected with a test tube. One mouth of the test tube 26 is connected to the C port of the tee 23 , and the other mouth is sealed with a flange 16 , and the flange 16 is reserved with an opening 22 for a sensing line.

[0022] The tee 23 is provided with a net pocket 21, and the net pocket 21 is provided with a temperature probe 18 and a flow sensor 20, and the temperature probe 18 and the flow sensor 20 are connected to the data acquisition module through the sensing line A17, the sensing line B19 and the data acquisition module respectively. Connect, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com