A kind of Naoxinshu oral liquid and preparation method thereof

A technology of Naoxinshu oral liquid and concentrated liquid, which is used in pharmaceutical formulations, dispersion liquid delivery, cardiovascular system diseases, etc., can solve the problems of long fermentation period, low content of active ingredients, unstable quality, etc. growth, increase polysaccharide production, and meet clinical needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

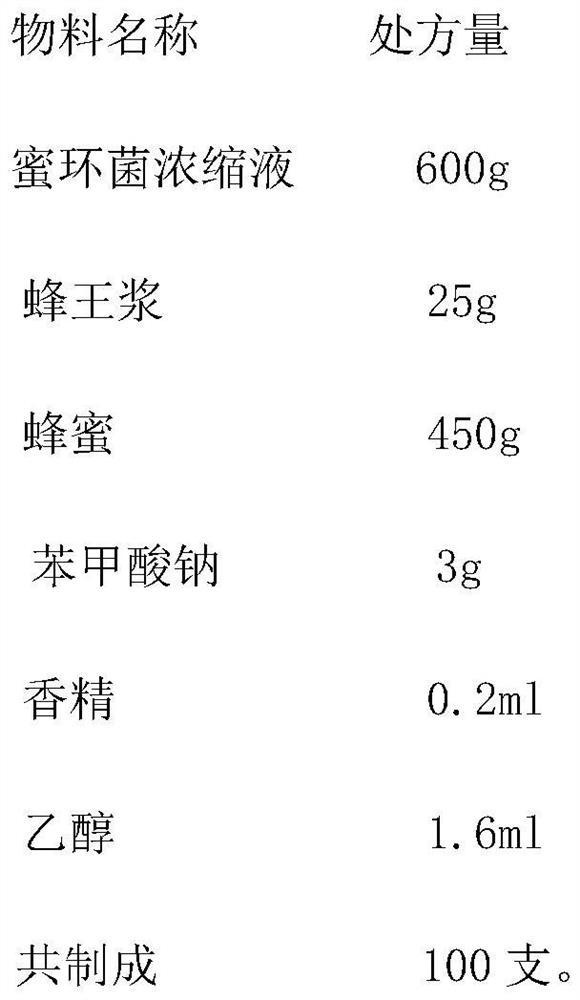

[0038] A preparation method of Naoxinshu oral liquid, comprising the following steps:

[0039] S1, the preparation of armillaria concentrated solution:

[0040] S11. Inoculate the Armillaria strain into the fermentation broth at a temperature of 26-28°C and a tank pressure of 0.05-0.08×10 5 Pa, fermented and cultivated for 3-5 days to obtain a fermented liquid;

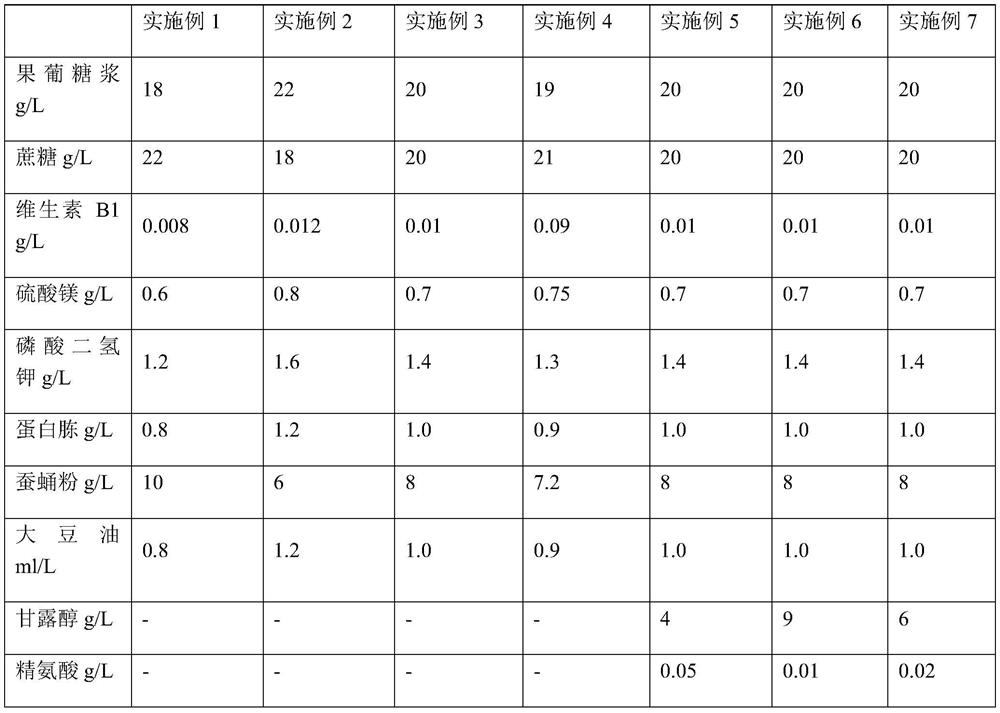

[0041] The fermentation culture liquid includes: fructose syrup 18-22g / L, sucrose 18-22g / L, vitamin B1 0.008-0.012g / L, magnesium sulfate 0.6-0.8g / L, potassium dihydrogen phosphate 1.2-1.6g / L L, peptone 0.8-1.2g / L, silkworm chrysalis powder 6-10g / L and soybean oil 0.8-1.2ml / L;

[0042] Preferably, the fermentation broth also includes 4-9g / L mannitol and 0.01-0.05g / L arginine;

[0043] S12, inactivating the fermented liquid obtained in step S11, filtering, and concentrating to obtain an Armillaria concentrated liquid;

[0044] The inactivation is as follows: after the fermentation is terminated, the temperature in t...

experiment example 1

[0068] 1. Extraction and determination of polysaccharides in fermentation broth

[0069] Take a certain volume of fermentation broth and centrifuge at 3000r / min for 10min, take 20mL of the supernatant and concentrate it to 10mL at 50°C, add 3 times the volume of ethanol to precipitate for 12h, centrifuge at 3000r / min for 15min, wash the precipitate with 75% ethanol Centrifuge until there is no reducing sugar reaction, and dissolve the precipitate fully with hot water at 60°C, centrifuge to remove the precipitate, and dilute the supernatant to a 100mL volumetric flask. The content of polysaccharides was determined by the phenol-sulfuric acid method.

[0070] 2. Measurement of the dry weight of mycelia in the fermentation broth

[0071] Filter the fermented product with two layers of gauze, take the mycelium and put it in air-drying at 45°C to constant weight, and convert it into the dry weight of mycelium per liter of fermentation broth.

[0072] The results are shown in Tabl...

experiment example 2

[0076] Experimental Example 2 Functional Evaluation of Lowering Blood Sugar

[0077] db / db diabetic mice: 5 weeks old, male, purchased from Institute of Model Animals, Nanjing University. Measure body weight, random blood sugar, remove rats with abnormal body weight and abnormal blood sugar, and randomly distribute them into 12 groups, 8 in each group; the Naoxinshu oral liquid prepared in Examples 1-7 and Comparative Examples 1-4, respectively, according to 1.08g The dose of / kg / d was administered to db / db diabetic mice by intragastric administration, once a day, for 4 consecutive weeks, and the model control group was given the same dose of normal saline. Fasting blood glucose was monitored weekly, that is, the night before the blood glucose measurement, the mice were fasted, and blood was taken from the tail vein for detection the next day. When measuring blood sugar, treat the mice gently, and try not to make the mice nervous, so as not to affect the accuracy. When measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com