Multi-azimuth tool clamp safety device

A technology of tooling fixtures and safety devices, applied in positioning devices, manufacturing tools, clamping, etc., can solve problems such as personnel injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

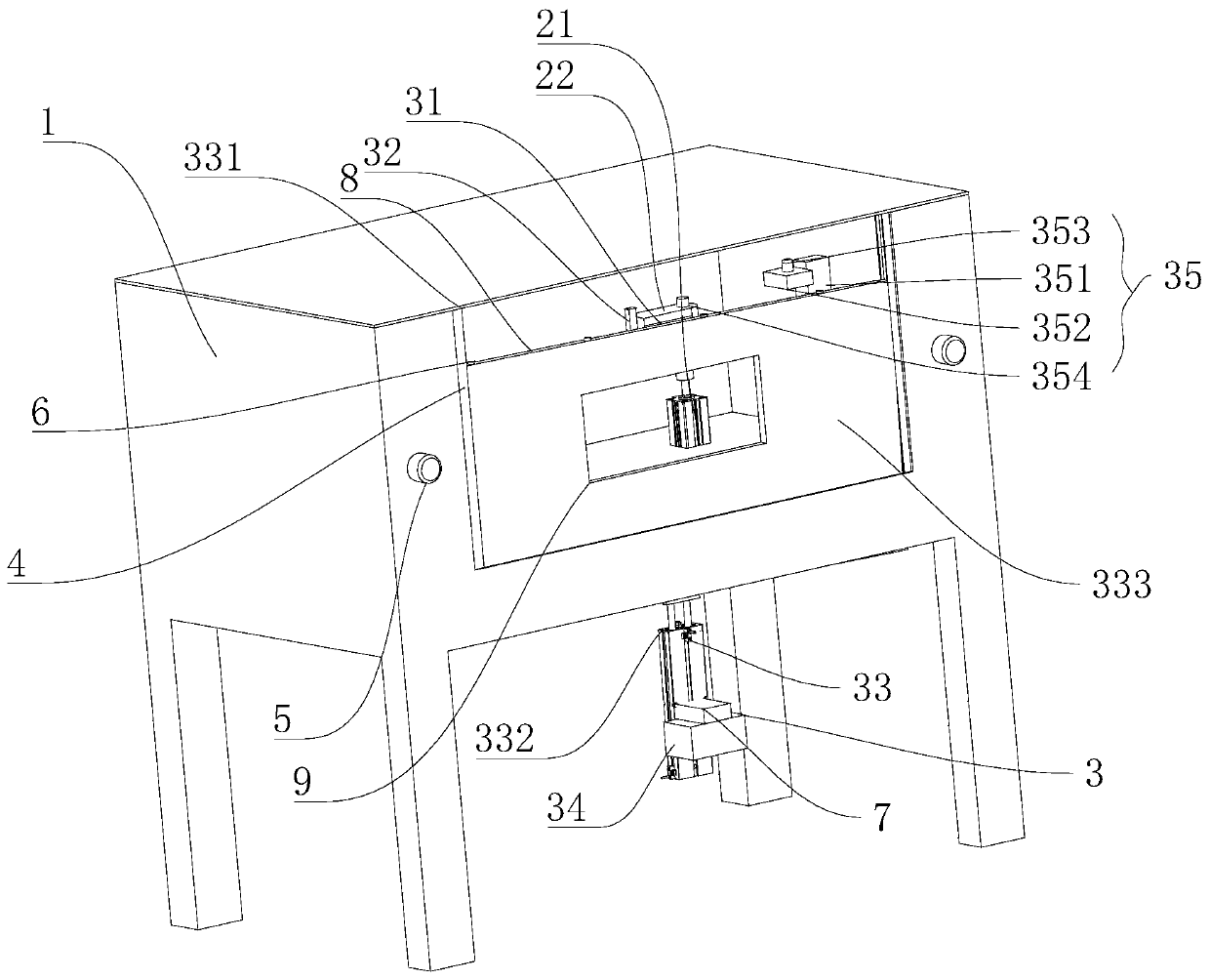

[0026] The technical solution adopted in the present invention is: a multi-directional fixture safety device, such as figure 1 As shown, the body 1 is included, the body 1 is provided with a clamping device 2, the clamping device 2 is provided with a detection device 3, the clamping device 2 includes a number of lifting cylinders 21 located on the body 1, and a lifting cylinder 21 located on the lifting cylinder 21. The lower pressing block 22 is provided, and the detection device 3 includes a soft extrusion pad 31 arranged on the upper surface of the clamping device 2, an infrared thermal sensor 32 is arranged above the clamping device 2, and simultaneously, an infrared thermal sensor 32 is arranged around the body 1. Lifting device 33 is arranged, and lifting device 33 comprises the opening 331 that is provided with on the edge of body 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com