A kind of guide vane processing method

A technology of guide vane and processing method, which is applied in the direction of metal processing equipment, manufacturing tools, grinding workpiece support, etc., can solve the problem that the blade throat equivalent is unstable, it is difficult to adjust to meet the design requirements, and the throat equivalent cannot meet the design requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

[0030] A kind of guide vane processing method of the present invention, comprises the following steps:

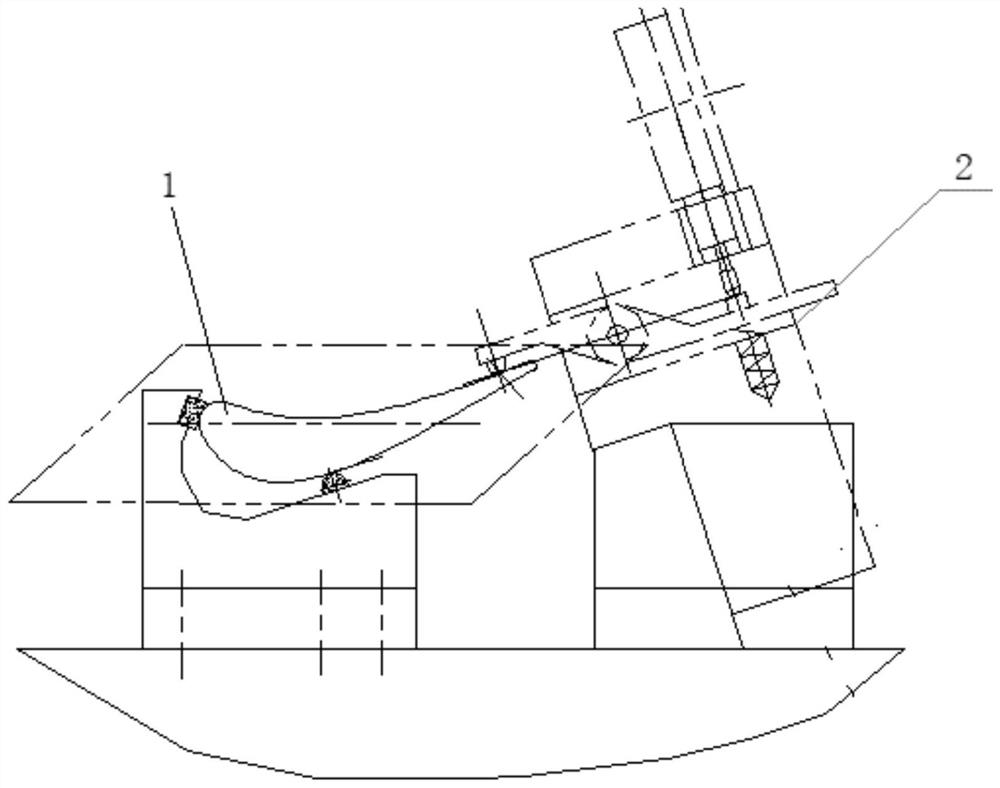

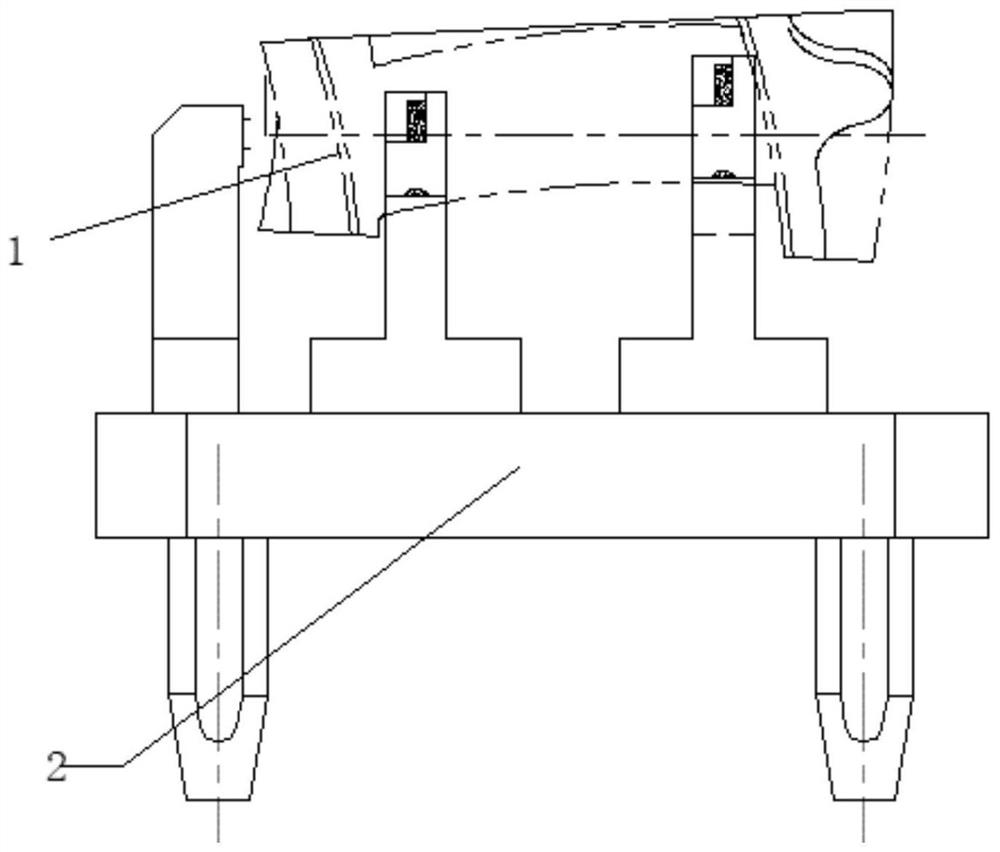

[0031] Step 1), fix the guide vane wool material 1 to be processed on the blade basin wedge surface processing fixture 2, such as figure 2 , image 3 As shown in , respectively measure the throat equivalent deviation of the cross-sections at both ends of the guide vane wool to be processed;

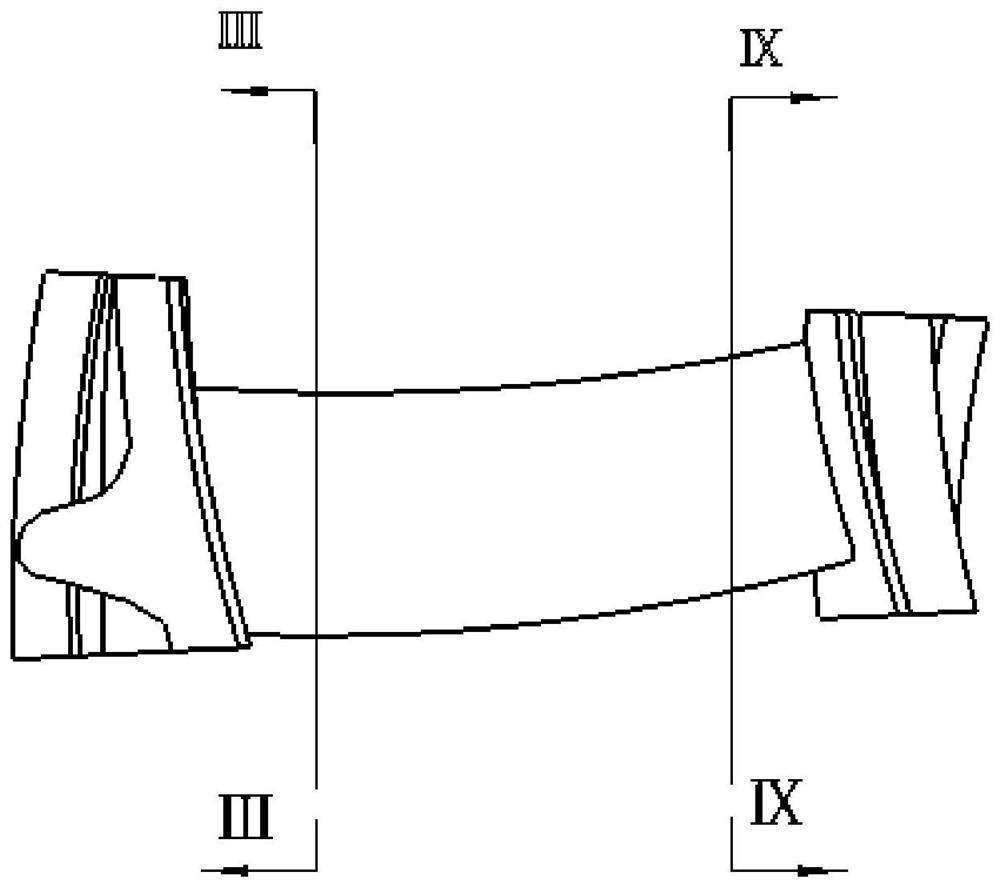

[0032] Specifically, the throat equivalent standard parts are used as the measuring parts for benchmarking, and then the guide blade wool to be processed is fixed on the wedge surface processing fixture of the blade basin, and the throat equivalent of the section throat equivalent at both ends of the guide blade wool to be processed is measured with a measuring bracket and a lever gauge , the difference between the throat equivalent value feature point and the throat equival...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com