pvdf organic polymer film capacitor

A polymer film and capacitor technology, applied in the direction of thin film/thick film capacitors, laminated capacitors, fixed capacitor electrodes, etc., can solve the problem that PVDF polymer films cannot be photolithographically etched, so as to avoid the easy breakdown of the tip effect and ensure reliability The effect of stability and avoidance of crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

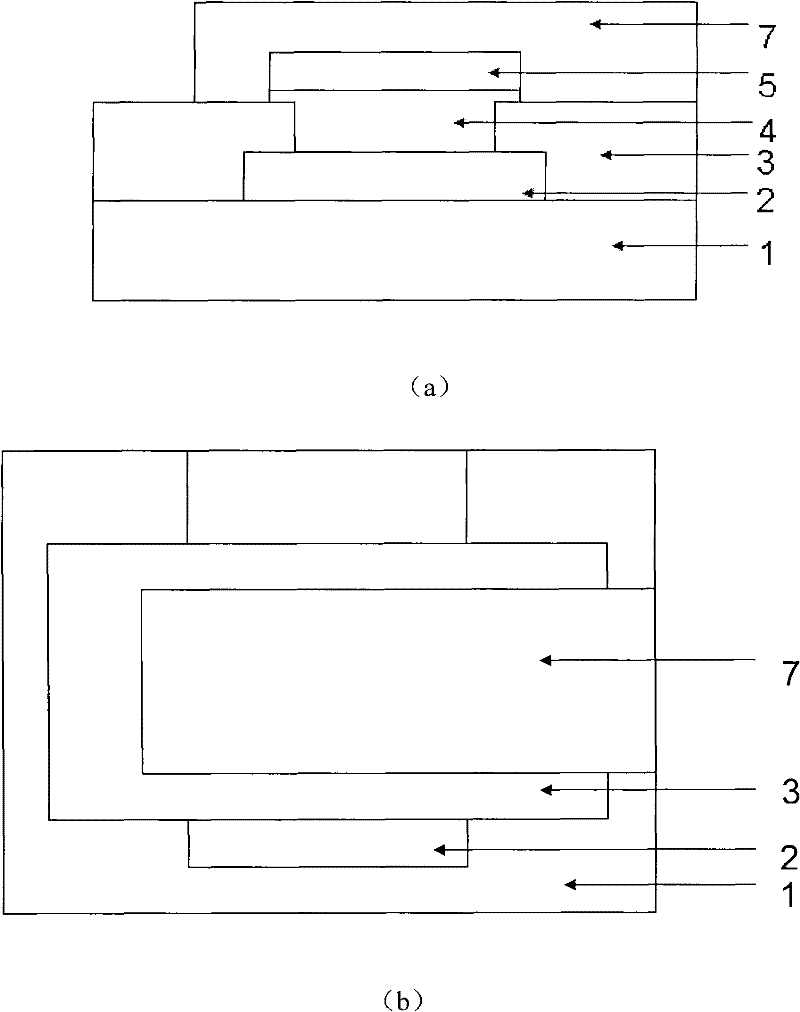

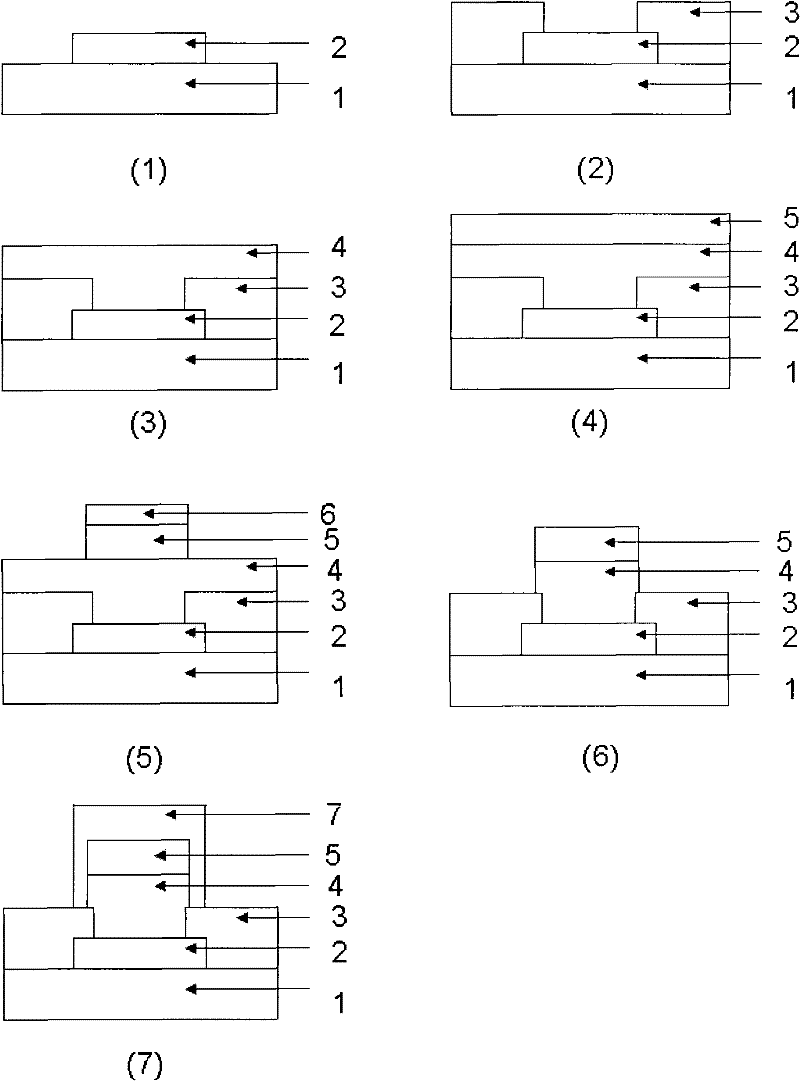

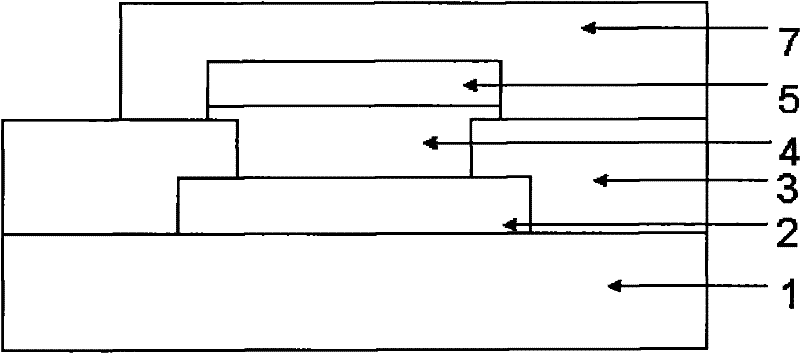

[0046] Please refer to the attached figure 1 , the PVDF organic polymer film capacitor device of this patent, its device structure includes:

[0047] A substrate 1, this substrate 1 is sapphire, silicon, gallium nitride or ITO glass;

[0048] A capacitor bottom electrode 2, the bottom electrode 2 is a square electrode, made on the substrate 1, an Al film with a thickness of not less than 100nm prepared for thermal evaporation;

[0049] A dielectric insulating layer 3, the dielectric insulating layer 3 is an open hole type, grown on the bottom electrode 2 and part of the substrate 1, completely covering part of the bottom electrode, the dielectric insulating layer 3 is silicon dioxide or nitrogen Silicon oxide dielectric film with a thickness not less than 300nm;

[0050] An organic polymer film 4, the organic polymer film grows on the opening of the dielectric insulating layer, the area is larger than the opening area of the dielectric insulating layer, and the edge falls ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com