Method for continuously preparing acesulfame potassium through micro-channel reactor

A technology of acesulfame potassium and microchannel reactor, which is applied in the chemical industry and can solve the problems of intermediate decomposition and yield reduction, which are not conducive to the stability of cyclization intermediates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention mainly aims at the intermittent synthesis of acesulfame potassium, and the problems of low yield, high energy consumption and high production cost in the process of cyclization and hydrolysis, and develops a method for continuously preparing acesulfame potassium through a microchannel reactor .

[0046] Its main process is as follows:

[0047] 1. The preparation of the acetoacetamidosulfonic acid triethylamine salt (DKA) solution is a continuous process.

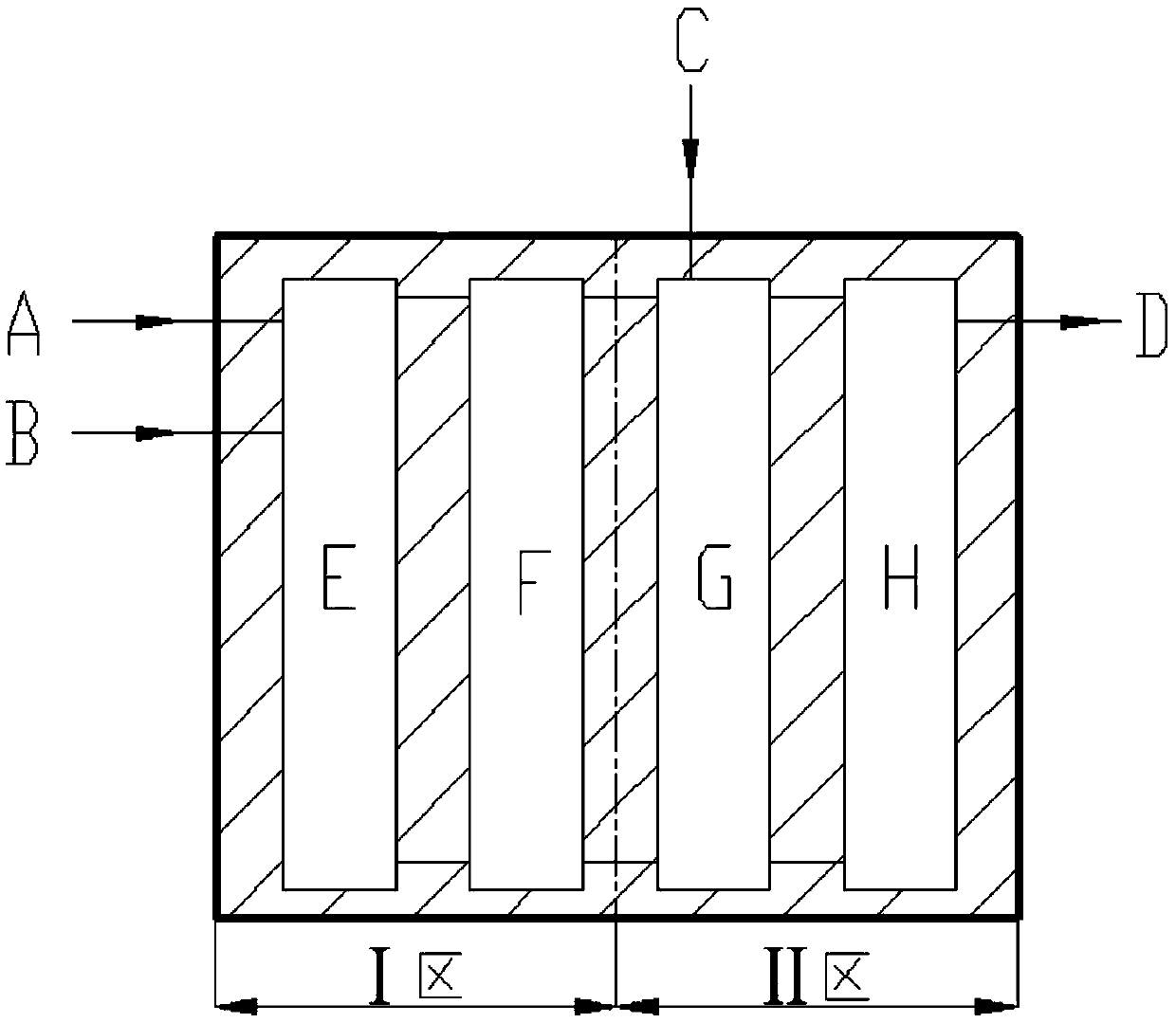

[0048] 2. The DKA solution and the cyclizing agent continuously enter the microreactor through the A and B interfaces of the microreactor, and after the full reaction of the mixing section and the reaction section, in the same reactor with the water continuously entering from the C interface, After fully mixing and reacting in the mixing section and the reaction section, the reaction solution of acesulfame is obtained from outlet D for continuous extraction.

[0049] 3. The feed ratio of the DK...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap