One-component halogen-free flame-retardant insulating impregnation resin and preparation method thereof

An insulation impregnation, one-component technology, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problem of mechanical property degradation of resin cured products, migration of non-reactive flame retardants, and unsaturated polyester resin chains. The problems such as the decrease of segmental unsaturated bond density can be solved, and the effects of good mechanical properties, clear and feasible mechanism, and excellent flame retardant performance can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

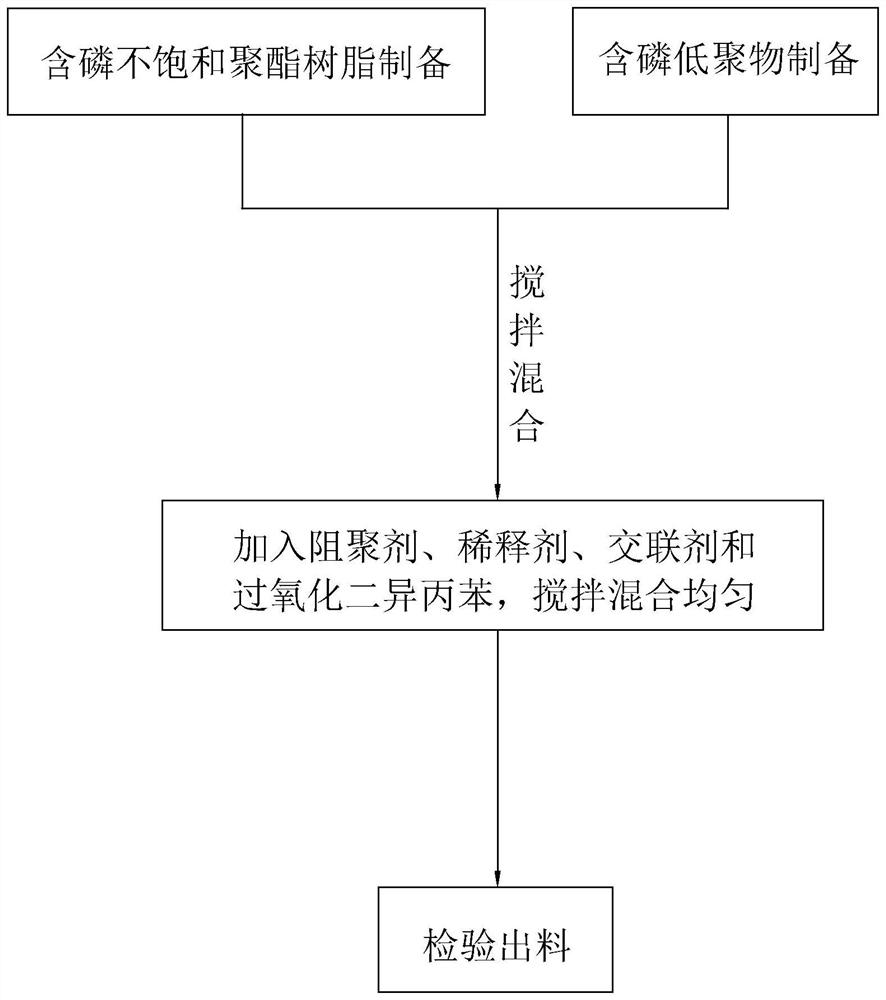

Method used

Image

Examples

Embodiment 1

[0044] Example 1: A single-component halogen-free flame-retardant insulating impregnated resin, each component and its corresponding parts by weight are shown in Table 1, and prepared by the following steps:

[0045] Step 1, preparation of phosphorus-containing unsaturated polyester resin: put corresponding parts by weight of 2-carboxyethylphenyl hypophosphorous acid and ethylene glycol with a percentage content of 40% into the reaction kettle, and react under the condition of 120°C 2h, then add the remaining ethylene glycol and all the fumaric acid, first react at 160°C for 4h, then raise the temperature to 210°C for 4h, when the acid value of the reaction system is lower than 50mgKOH / g, Stop the reaction and cool down to 80°C;

[0046] Step 2, preparation of phosphorus-containing oligomers: Put corresponding parts by weight of 2-carboxyethylphenylphosphinic acid and ethylene glycol into the reactor, react at 120°C for 2 hours, and then reduce the pressure to -0.095MPa Vacuu...

Embodiment 2-7

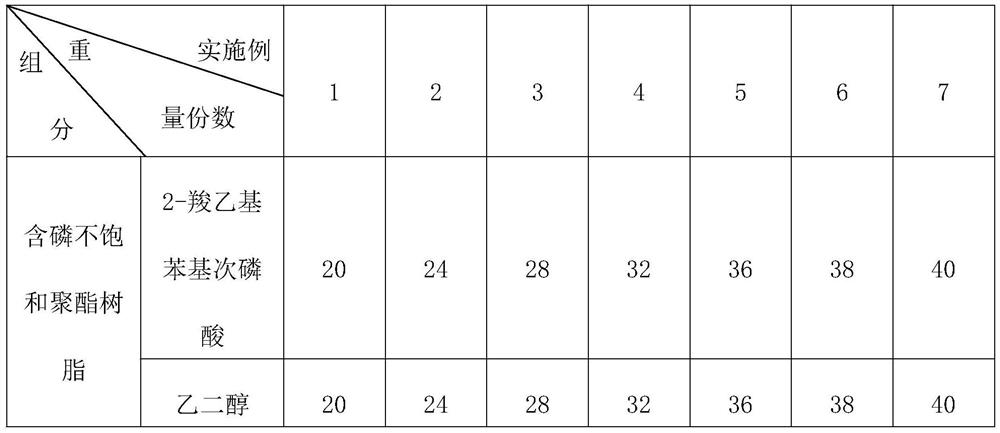

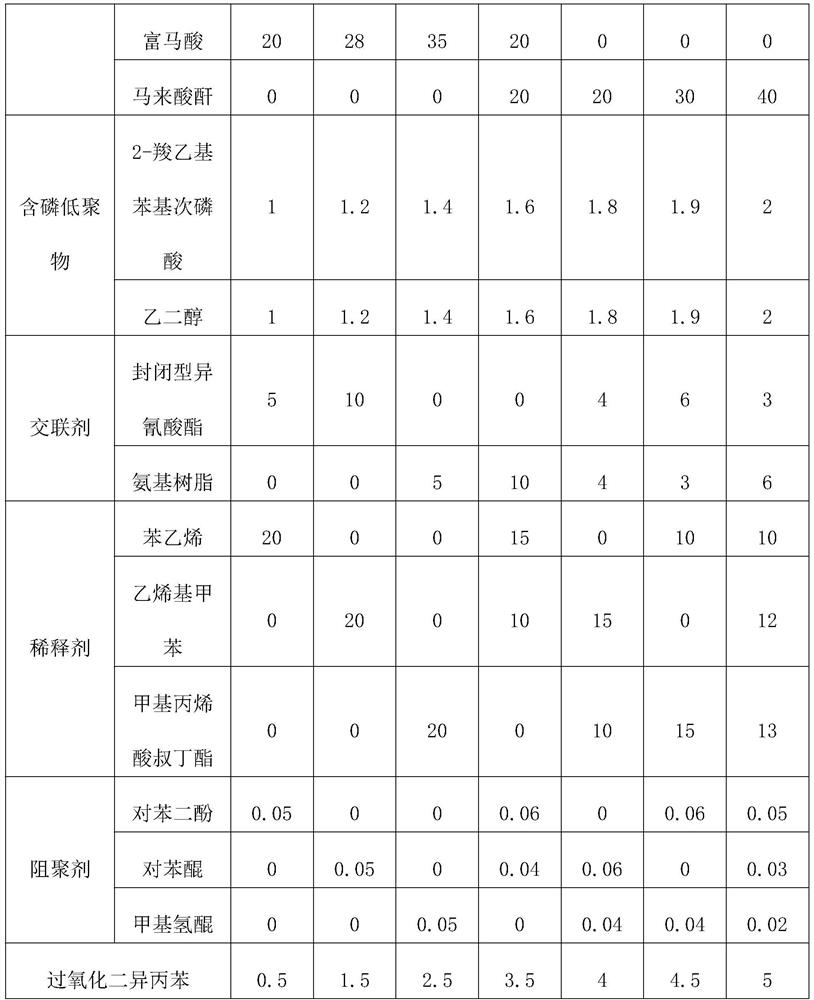

[0048]Example 2-7: A single-component halogen-free flame-retardant insulating impregnated resin, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0049] Each component and parts by weight thereof in table 1 embodiment 1-7

[0050]

[0051]

Embodiment 8

[0052] Example 8: A method for preparing a single-component halogen-free flame-retardant insulating impregnated resin, which is different from Example 1 in that:

[0053] Step 1, preparation of phosphorus-containing unsaturated polyester resin: put corresponding parts by weight of hydroxymethylphenyl hypophosphorous acid and ethylene glycol with a percentage content of 40% into the reaction kettle, and react at 120° C. for 2 hours, Then add the remaining ethylene glycol and all the fumaric acid, first react at 160°C for 4h, then raise the temperature to 210°C for 4h, stop the reaction when the acid value of the reaction system is lower than 50mgKOH / g , cooled to 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com