Sliding formwork system

A slip form and formwork technology, applied in the field of slip form systems, can solve the problem that it is difficult for construction personnel to check whether there are cracks on the surface, affect the appearance of construction quality, cracks and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

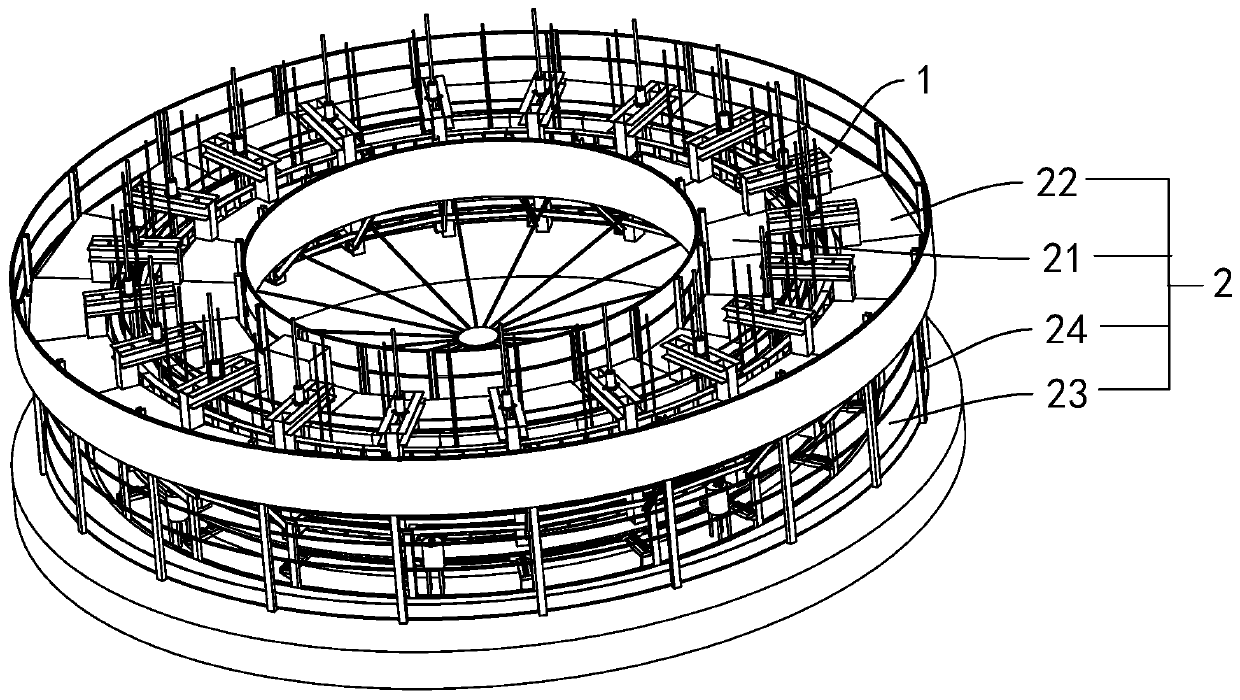

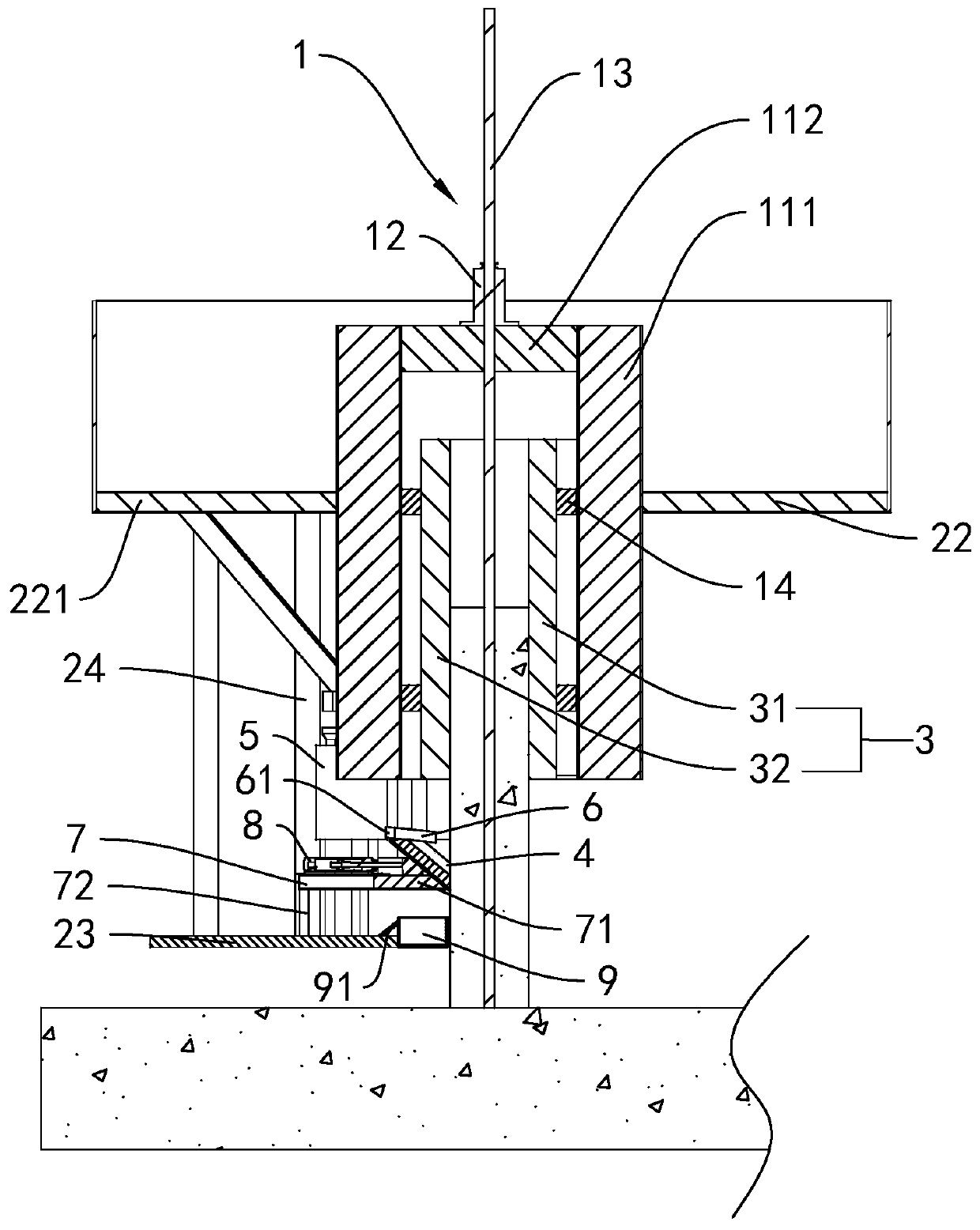

[0035] refer to figure 1 , figure 2 , is a sliding form system disclosed in the present invention, including a lifting frame system 1 , a platform system 2 and a formwork system 3 .

[0036] The formwork system 3 includes an inner circle formwork 31 and an outer circle formwork 32 which are both ring-shaped and arranged concentrically, and there is a distance between the inner circle formwork 31 and the outer circle formwork 32 . The space left between the inner ring formwork 31 and the outer ring formwork 32 is a pouring area for concrete pouring.

[0037] The lifting frame system 1 includes portal frames 11 arranged at intervals along the circumferential direction of the pouring area formed by the inner ring formwork 31 and the outer ring formwork 32. The portal frame 11 includes two vertical columns 111 and a The beam 112 at the top between 111, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com