Expansion sleeve joint capable of improving liquid sealing performance

A technology of expanding casing and liquid sealing, which is applied in the direction of casing, drilling pipe, drilling equipment, etc., and can solve the problems of poor sealing performance and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Taking a joint structure suitable for an expansion sleeve as an example, the present invention will be further described in detail.

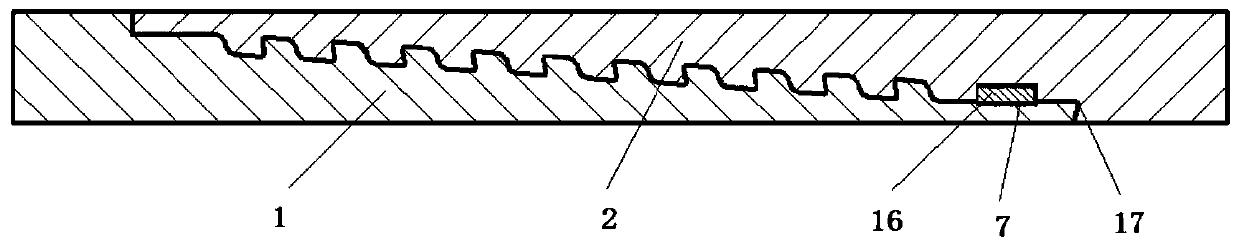

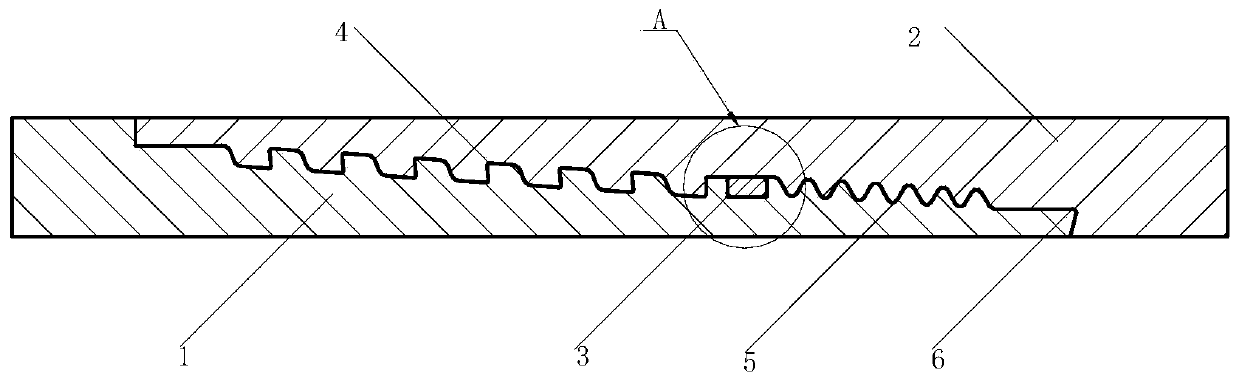

[0047] Refer to figure 2 , The joint structure suitable for expansion sleeve is mainly composed of male threaded joint 1 and female threaded joint 2.

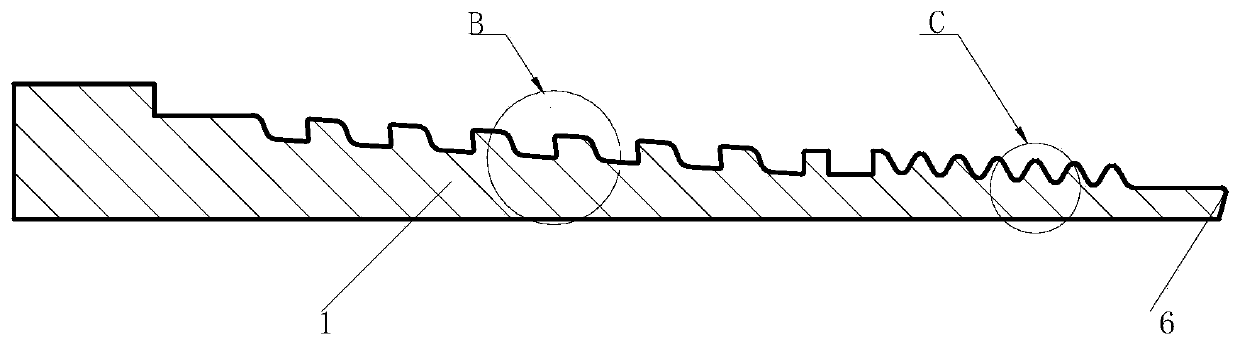

[0048] Refer to image 3 , The male threaded joint 1 of the expansion sleeve includes a negative angle torque shoulder 6, an API round thread 5, a sealing groove 7 and a barbed thread 4 from the outside.

[0049] Refer to figure 2 , The negative angle torque shoulder 6 of the male threaded joint 1 and the negative angle torque shoulder 6 of the inner end of the female threaded joint 2 are matched, and they are in interference contact when the diameter is expanded, which serves as the first auxiliary sealing function.

[0050] Refer to figure 2 with Image 6 , The improved API round thread 5 of the male threaded joint 1 is matched with the improved API round thread 5 of the female threaded joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com