Method for improving solder resist oil leakage of PCB

A kind of PCB board and solder mask technology, applied in the field of PCB board production, can solve the problems of slow production of special plug hole oil, anti-welding oil, affecting appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

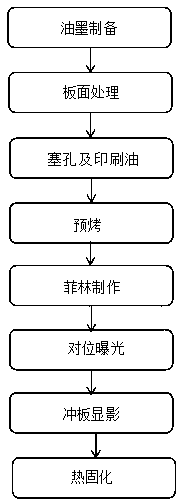

[0025] Such as figure 1 As shown, the embodiment of the present invention provides a method for improving solder resistance and oil leakage of PCB board, including the following steps:

[0026] Ink preparation, add 5-8ml plug thinner to 1kg plug oil and stir evenly; add 20-45ml top oil thinner to 1kg top oil and stir evenly.

[0027] Process the PCB board 1, pass the PCB board 1 through the brushing machine before printing the solder mask, control the current of the upper line brush board to 2.2A, the speed is 2.5m / min, and the offline brush board current is 3.4A, and the speed is 2.5m / min.

[0028] For plugging and printing oil, the plugging oil is used to carry out the plugging oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com