A kind of rubber tree seedling bud grafting method for rootstock seedling exempting from smearing buds

A technology for budding of seedlings and rootstock seedlings, applied in the field of budding and seedlings, can solve the problems of tedious, time-consuming and labor-intensive wiping work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

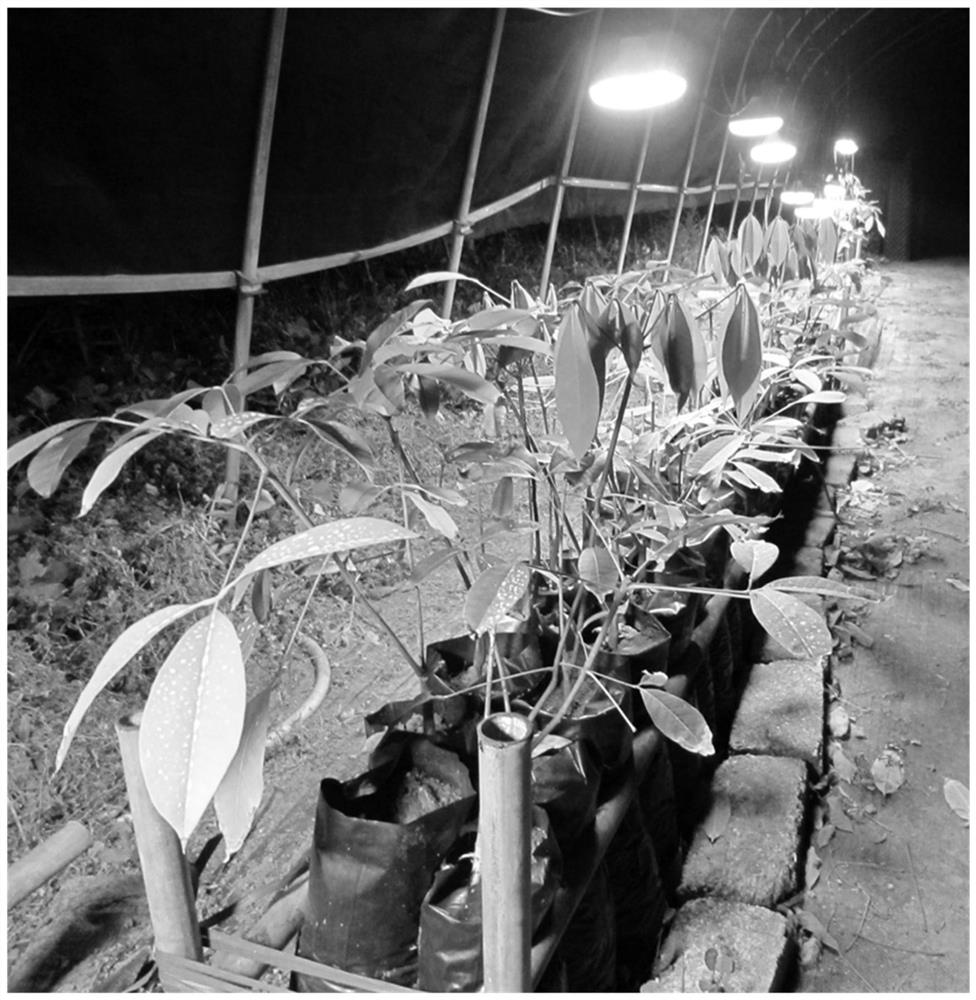

Image

Examples

Embodiment 1

[0033] A kind of rubber tree seedling bud grafting rootstock seedling avoids the method for smearing bud, comprises the steps:

[0034] (1) sow rubber tree seeds, treat the seedlings to grow for more than 20 days, and carry out seedling budding when the first pair of blades are not unfolded, and the rubber tree seedling budding rootstock seedlings that complete the budding are planted in plastic greenhouses, and the seedling budding rootstock seedlings are planted in plastic greenhouses. When the 2nd or 3rd awning leaves are stable, topping is carried out, and the topping is to cut the anvil at 1.0cm below the first pair of leaves of the rootstock seedlings after seedling budding, and remove the top part; the scion is Reyan 7-33-97 or Clonal bud slices of Reyan 7-20-59;

[0035] (2) After topping, use lamps for night illumination on the second day, and use lamps for night illumination above the seedling budding piles. The distance between the lamps and the seedling budding pil...

Embodiment 2

[0038] On the basis of embodiment 1, topping in step (1) is to cut the anvil at 0.5cm below the first pair of blades of rubber tree seedling budding rootstock seedling, remove the top part, in step (2), the lamp distance from seedling The distance between the budding piles is 50cm, the light intensity is 20000LUX, and all the other steps are the same as in Example 1.

Embodiment 3

[0040] On the basis of Example 1, topping in step (1) is to cut the anvil at 0.2cm below the first pair of blades of the seedling budding rootstock seedling, remove the top part, and in step (2), the distance between the light fixture and the seedling grafting The distance of bud pile is 60cm, and light intensity is 22000LUX, and all the other steps are all the same as embodiment 1.

[0041] In the foregoing embodiment, during the whole seedling cultivation period, in order to prevent powdery mildew, it is necessary to spray sulfur powder water solvent on seedlings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com