Punching blanking die

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] As for example figure 1 -example Image 6 Shown:

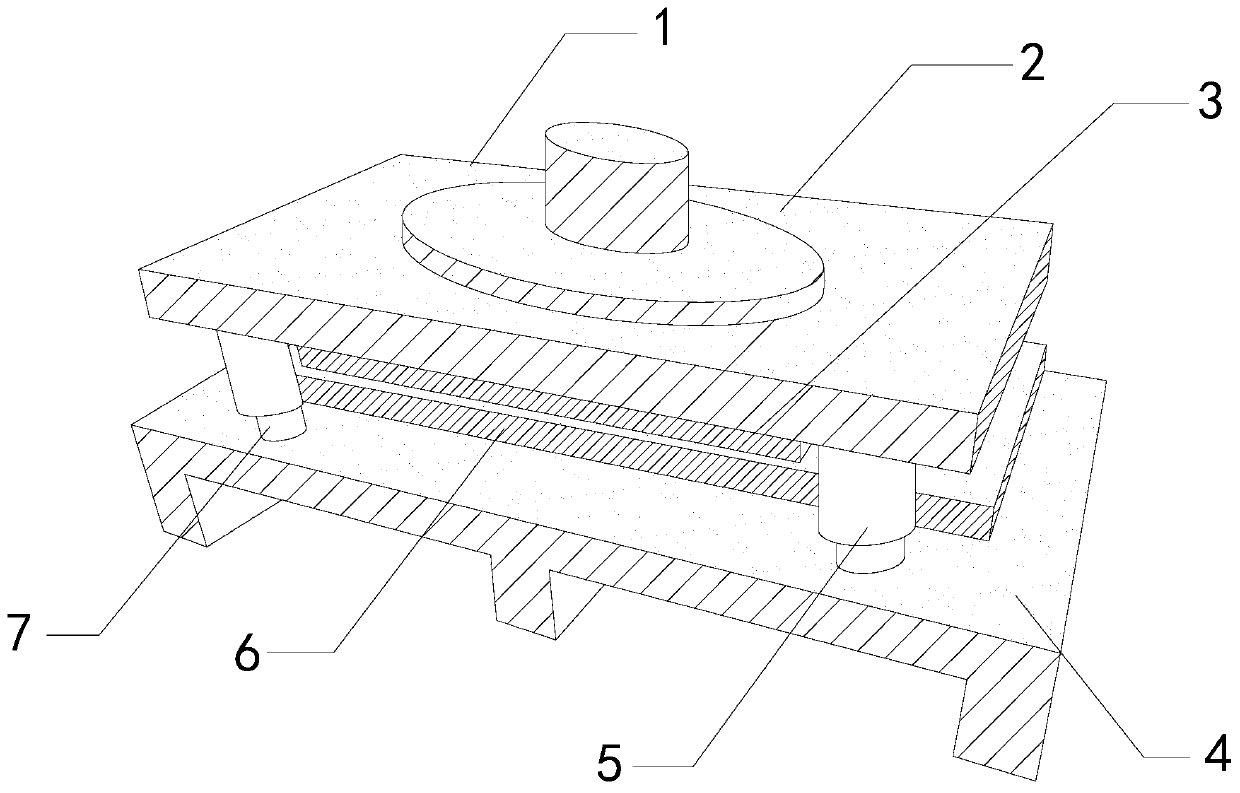

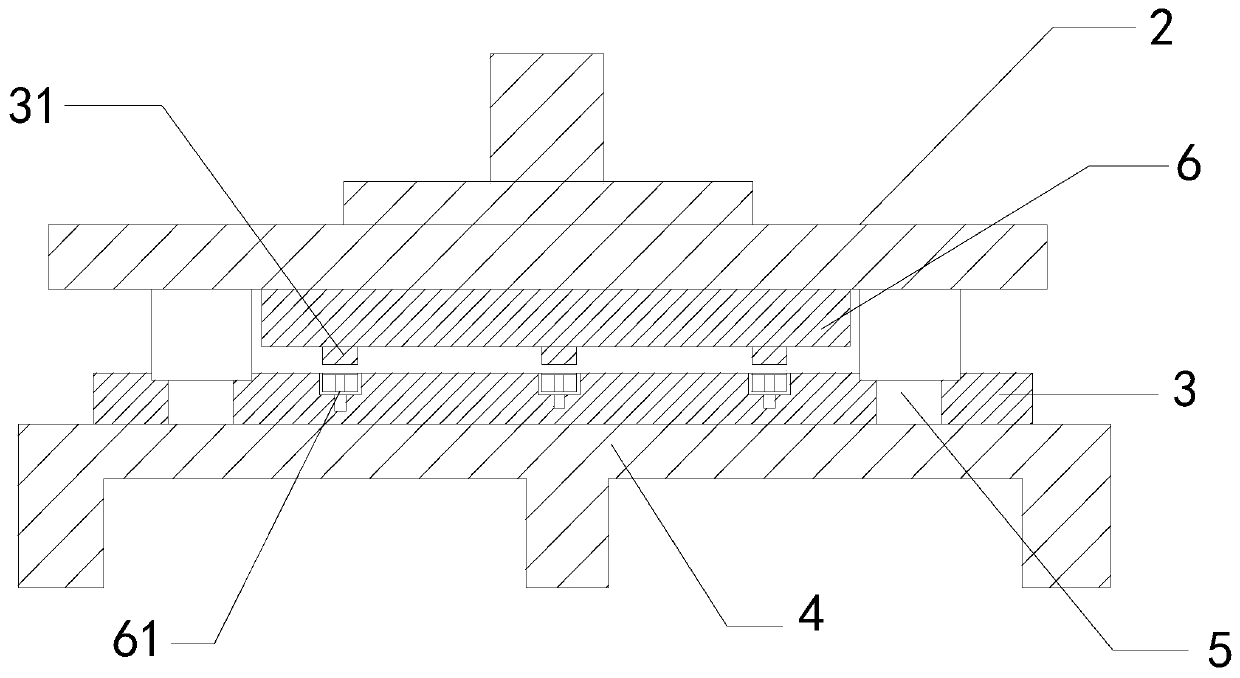

[0028] The present invention provides a punching and blanking die, the structure of which includes a die 1, an upper die seat 2, a convex template 3, a base 4, a guide sleeve 5, a concave template 6, a guide post 7, a punching convex die 31, and a concave die groove 61, The upper mold base 2 is fixed to the upper end position of the mold 1, the convex template 3 is fixedly connected to the upper mold base 2, the base 4 is fixed to the lower end position of the mold 1, and the guide sleeve 5 and the upper mold base 2 Embedded connection, the concave template 6 is embedded and connected with the base 4, one end of the guide post 7 is in clearance fit with the guide sleeve 5, the other end of the guide post 7 is embedded and connected with the base 4, the punching punch 31 is provided with three embedding connections with the male template 3, and three female mold grooves 61 are provided on the female template 6.

[0029] The ...

Embodiment 2

[0035] As for example Figure 7 -example Picture 9 Shown:

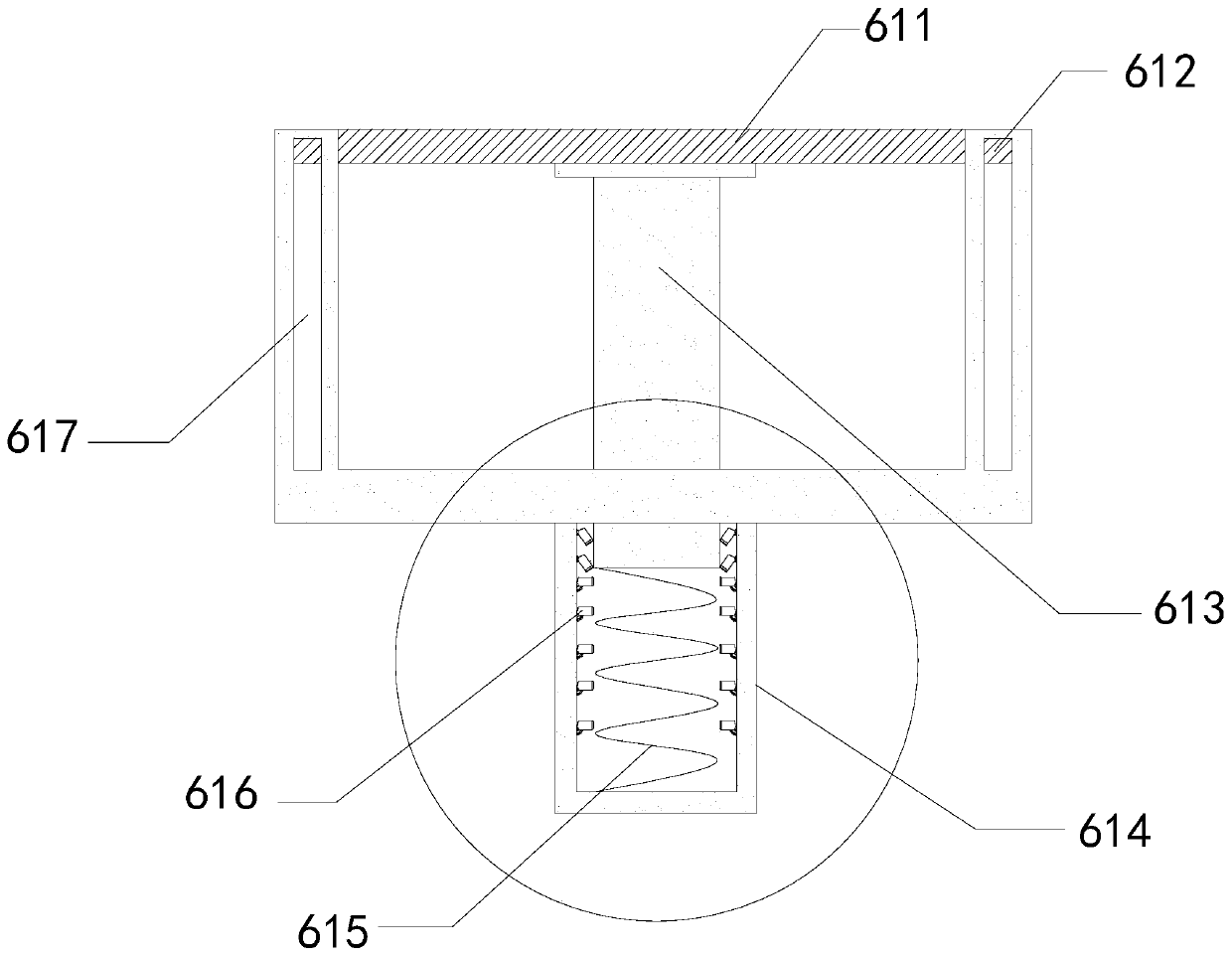

[0036] Among them, the rebound device a1 is mainly composed of a reset spring a11, a movable rod a12, and a blocking block a13. The reset spring a11 is fixed to the outer position of the movable rod a12, and one end of the movable rod a12 is embedded in the inner wall of the catheter 614. The other end of the movable rod a12 is in clearance fit with the movable block a2, the blocking block a13 is embedded and fixedly connected with the movable rod a12, and the movable rod a12 is of an arc structure, so as to move with the movable block a2. The trajectory fits well.

[0037] Wherein, the front end of the rubber block a3 is provided with rubber bumps a31, the rubber bumps are provided with thirty-six, and are evenly distributed on the front end surface of the rubber block a3, which can strengthen the surface of the rubber block a3 and the lifting rod 613 The friction force improves the cushioning effect of the cushioning ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap