Brazing process and device of tube-shell type heat exchanger

A shell-and-tube heat exchanger and brazing process technology, applied in auxiliary devices, manufacturing tools, metal processing and other directions, can solve the problems of poor seam filling performance, uneven flow of molten liquid brazing material, and difficulty in popularization and application. , to improve work efficiency, shorten brazing time, and improve the effect of caulking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

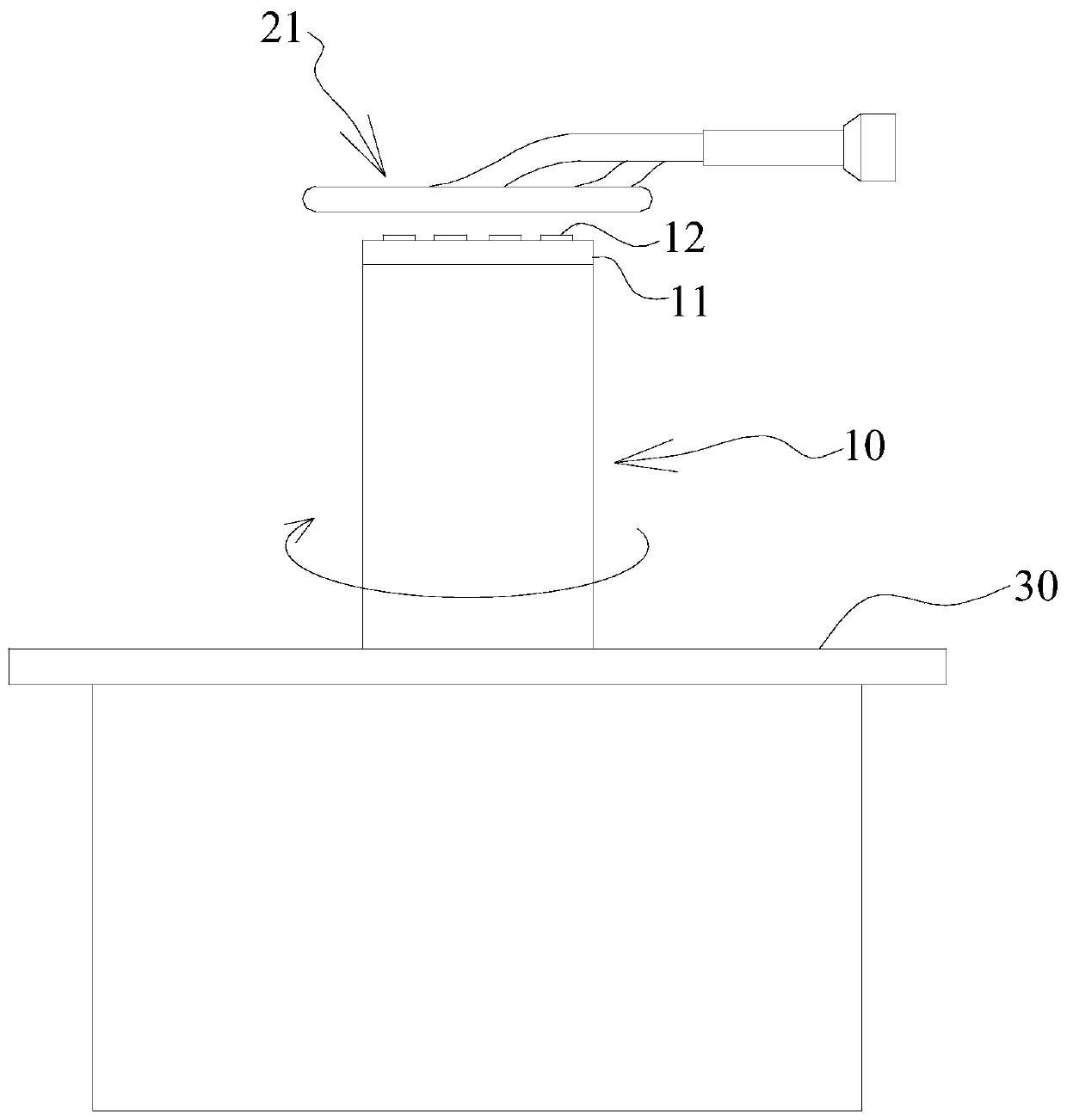

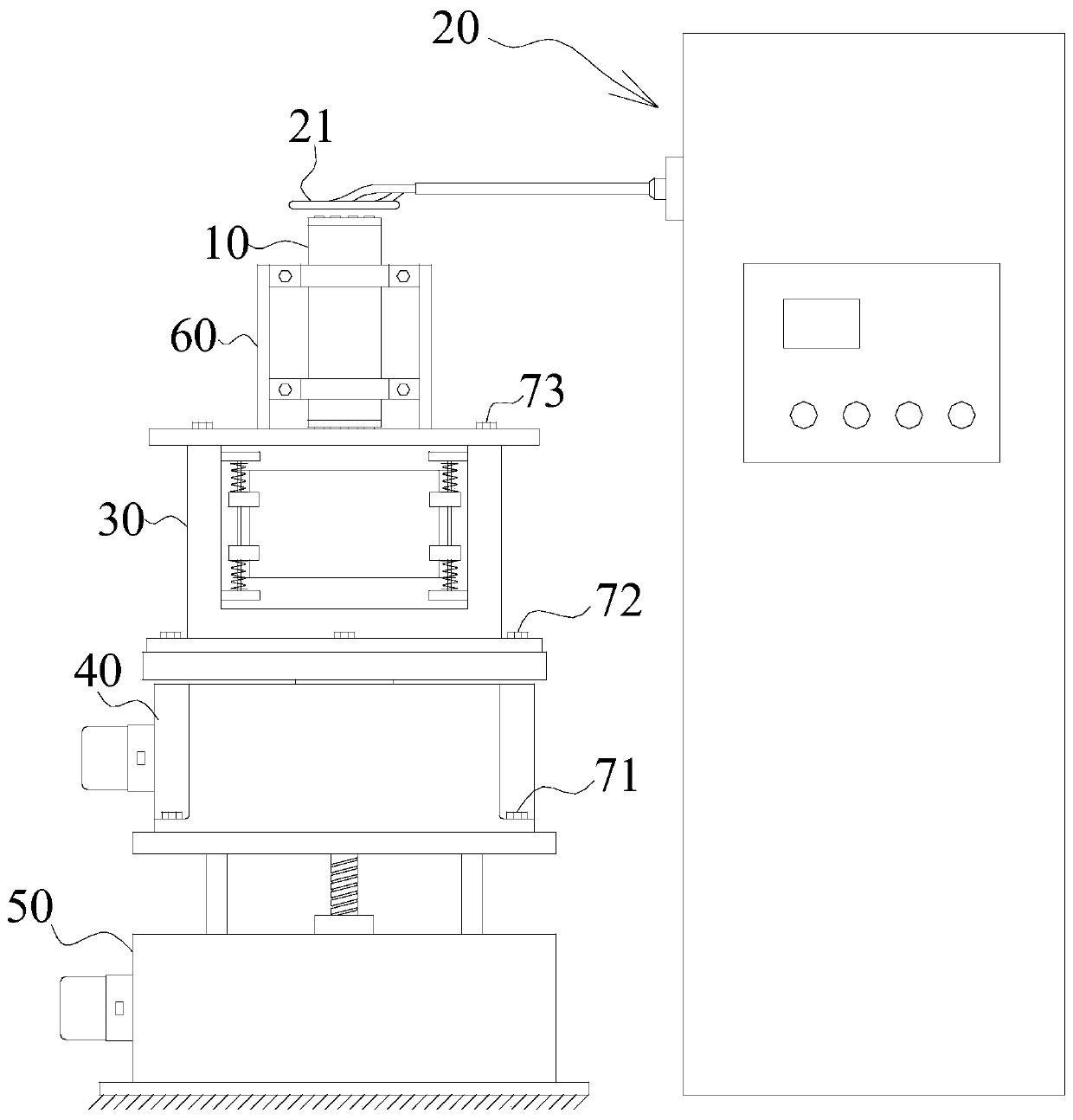

[0037] like Figure 1-4 As shown, this embodiment provides a brazing process for a shell-and-tube heat exchanger. The brazing process is used to melt the brazing filler metal 13 between the tube sheet 11 and the heat exchange tube 12, and to assist lifting by mechanical vibration. The flow uniformity of the brazing filler metal 13 is improved to improve the caulking effect of the brazing filler metal 13 .

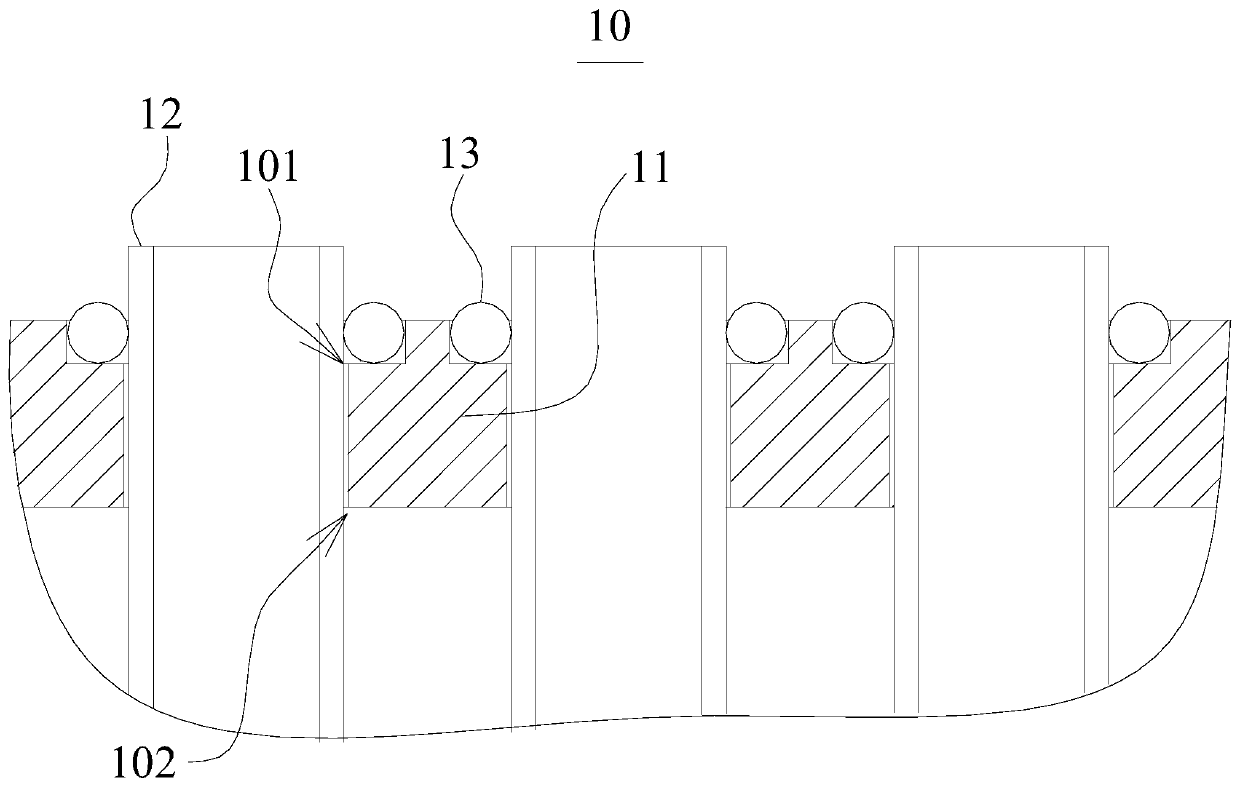

[0038] The brazing process of the shell-and-tube heat exchanger in this embodiment is suitable for brazing the core assembly 10 of the shell-and-tube heat exchanger. The core assembly 10 includes a tube sheet 11 and a heat exchange tube 12. On the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap