Novel precision composite six-axis linkage numerical control machine tool

A technology of six-axis linkage and CNC machine tools, which is applied in the direction of automatic control devices, large fixed members, metal processing machinery parts, etc., and can solve the problems of concentrated processes, weak multi-purpose functions of one machine, and low adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

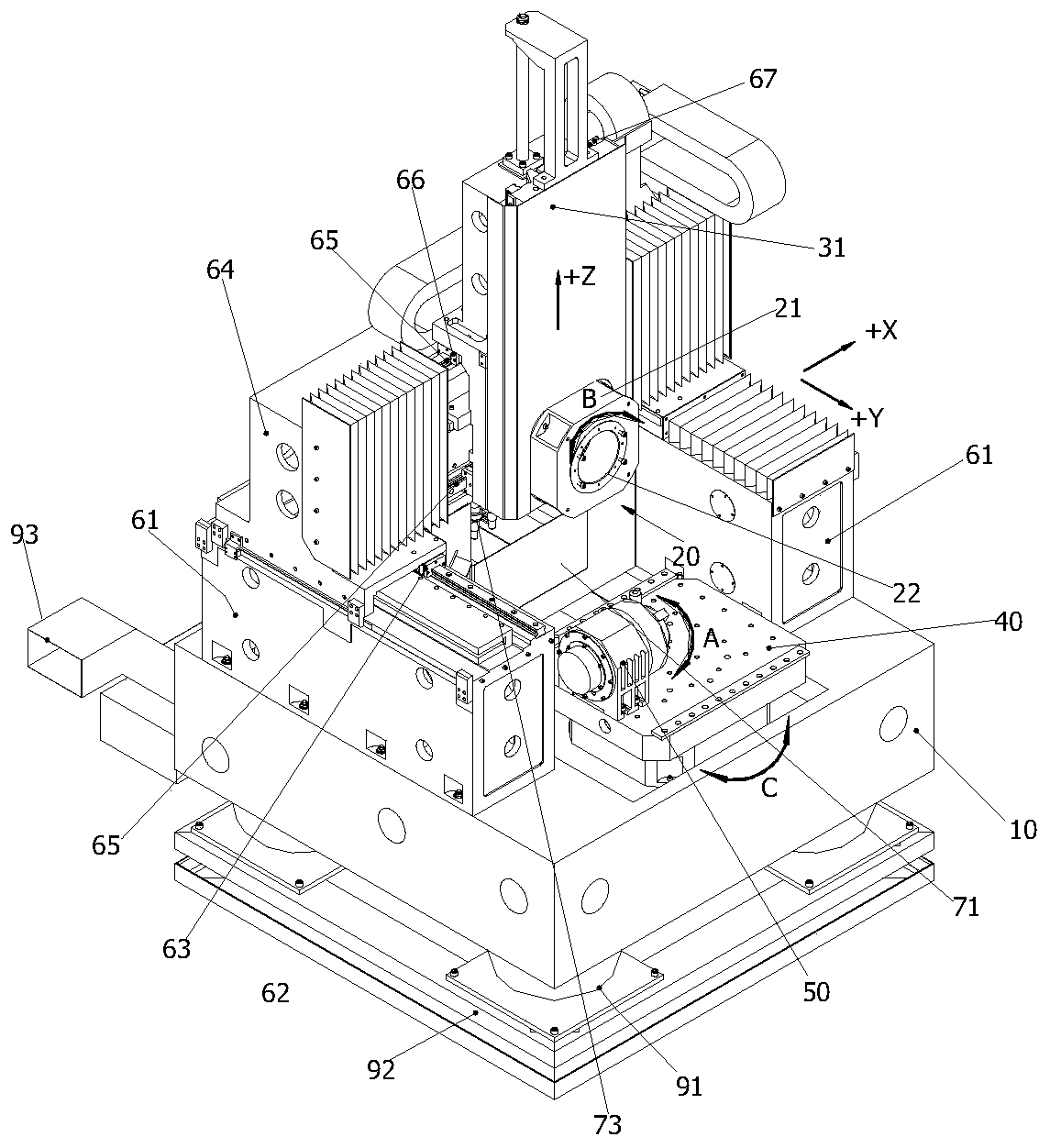

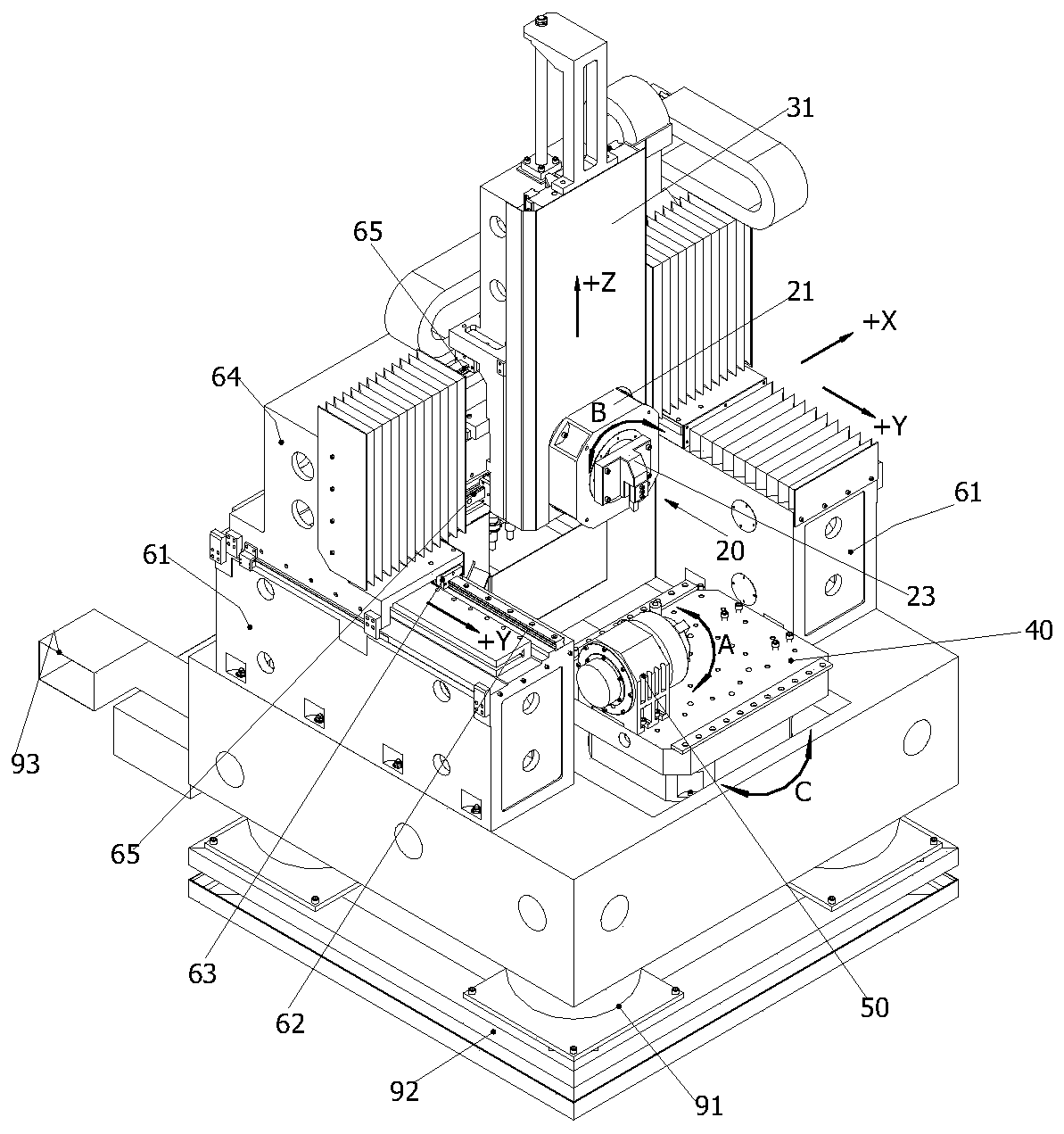

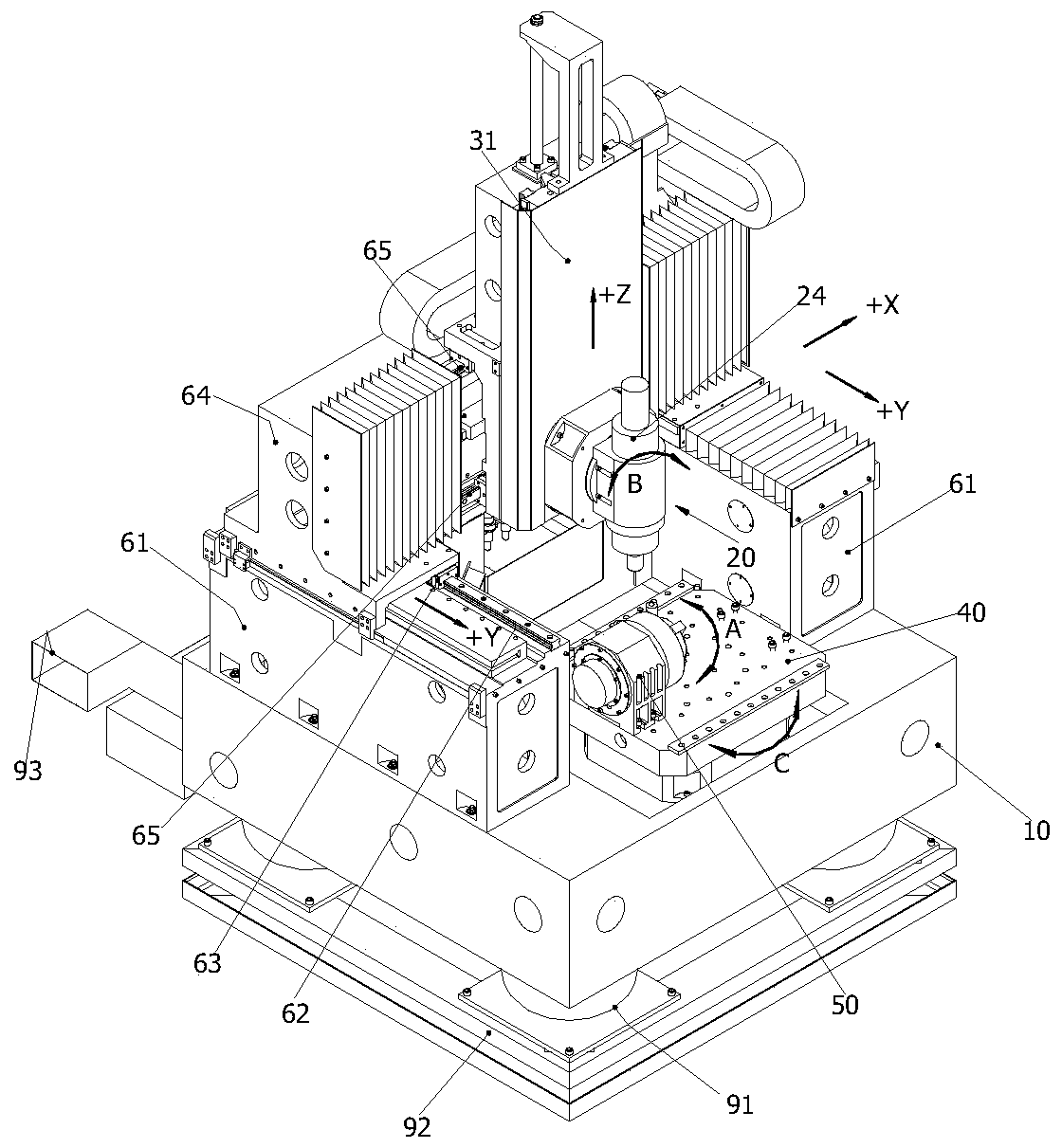

[0013] Combine below Figure 1-Figure 7 The present invention is discussed in further detail.

[0014] A new precision compound six-axis linkage CNC machine tool. The bed 10 is provided with a tool seat 20 for clamping tools. The tool seat 20 is installed on the slide seat 31, and the tool seat 20 swings in the vertical plane relative to the slide seat 31. (that is, rotate around the B axis in the figure), the bed 10 is provided with a Z-axis drive device that drives the slide 31 to move up and down, and an X-axis drive device and a Y-axis drive device that move along the X and Y directions. The body 10 is also provided with a rotary processing platform 40, and the rotary processing platform 40 is provided with a clamping mechanism 50 for clamping the workpiece and making it rotate and position. ) is consistent with the Z direction, and the center of rotation of the clamping mechanism 50 (that is, the A axis shown in the figure) is consistent with the X direction. Due to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com