Glove box ultrasonic welding equipment capable of rapidly changing mould

An ultrasonic welding and glove box technology, which is applied in the field of automobile interior welding, can solve the problem that ultrasonic welding equipment cannot perform mold change and mold change efficiency, etc., and achieve the effect of improving mold changing efficiency, reducing manufacturing cost, and simple and convenient mold changing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

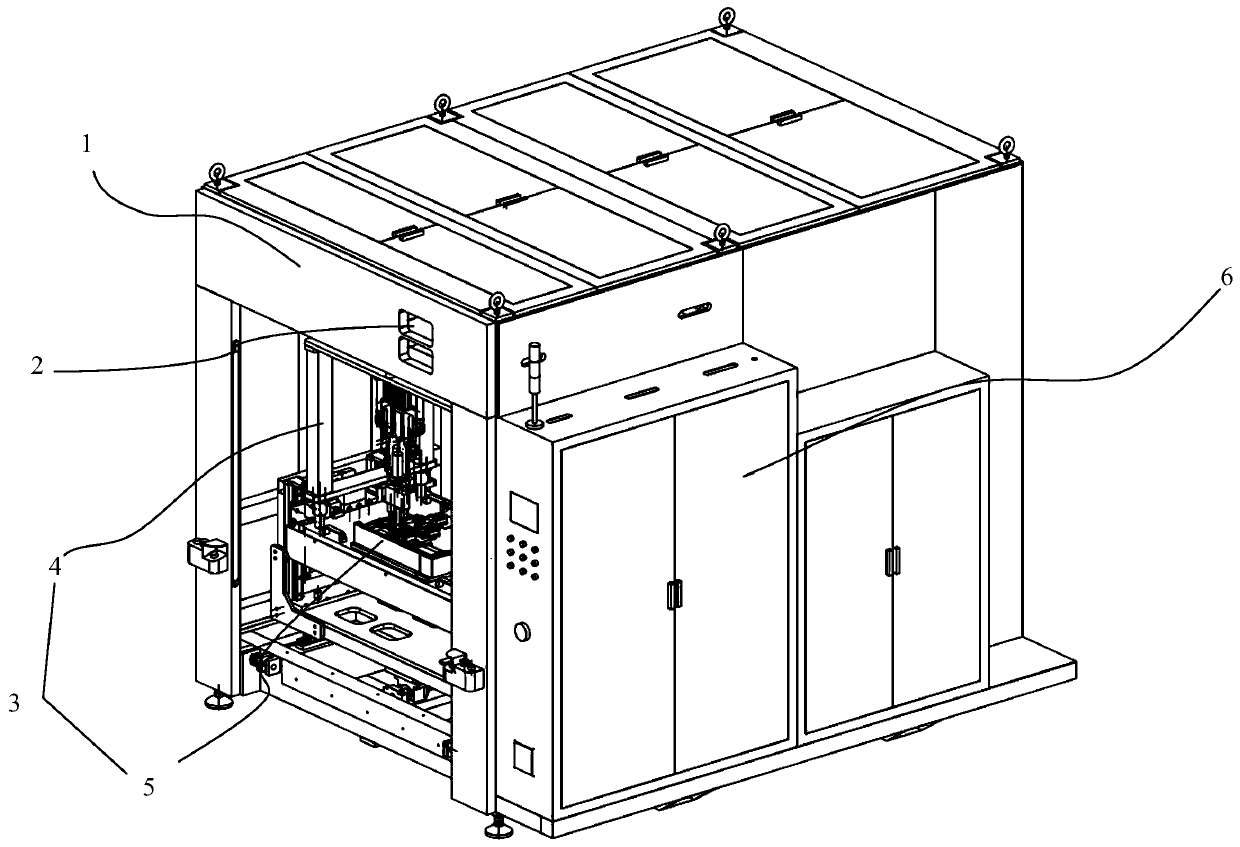

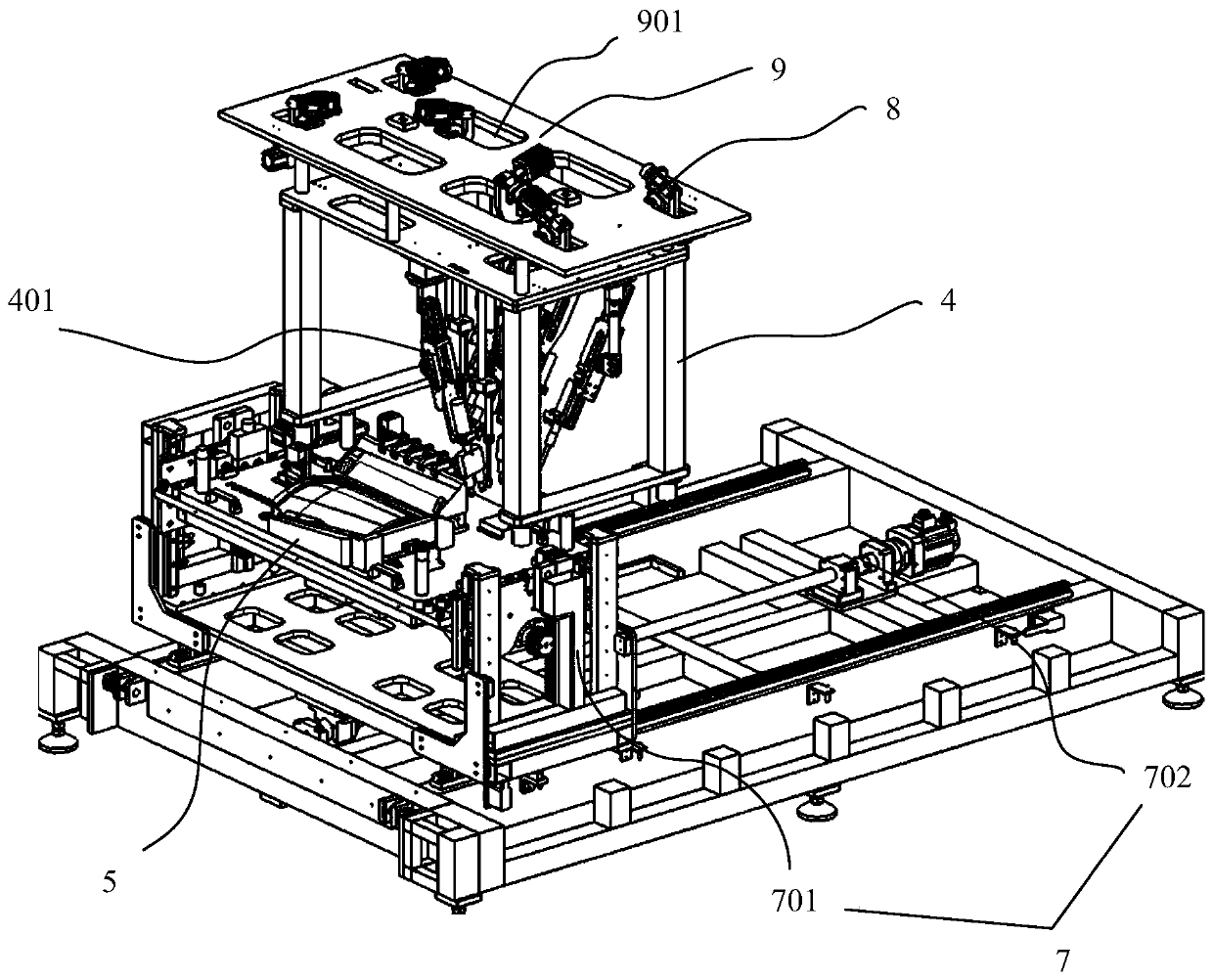

[0036] Such as figure 1 , figure 2 In the shown embodiment 1, a glove box ultrasonic welding equipment that can quickly change molds includes an equipment frame 1, and an equipment control unit 6 is arranged on the equipment frame 1, wherein the equipment frame 1 is used to support the entire ultrasonic welding equipment, the equipment control unit 6 is installed outside the equipment frame 1, and the equipment control unit 6 is used to control the opening and closing of the ultrasonic generator 2 to realize ultrasonic welding. The equipment control unit 6 is also used to control the locking mechanism 8, that is, when the equipment is changed Timely control the locking mechanism 8 to quickly lock the welding mold; the ultrasonic generator 2, the ultrasonic generator 2 is arranged on the equipment frame 1, and the ultrasonic generator 2 is used to generate ultrasonic waves to perform ultrasonic welding work; the welding mold 3, the welding mold 3 Removable and fixed on the eq...

Embodiment 2

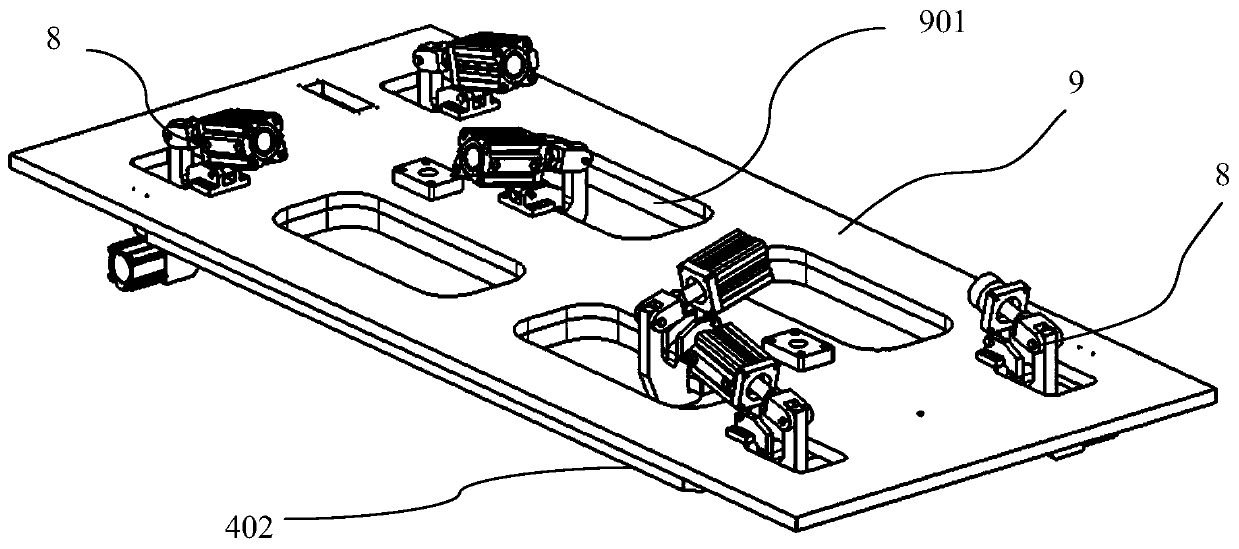

[0041] Such as Figure 4 , Figure 5 As shown, the technical solution of embodiment 2 is basically the same as the technical solution of embodiment 1, the difference is that the locking mechanism 8 includes a fixing module 801 and a latch module 808, and the fixing module 801 includes a fixing module 801 for fixing the welding upper mold 4 The fixed hook 807, the first cylinder 802 for controlling the fixed hook 807, the first connecting plate 803 and the first hinge 804 for connecting the first cylinder 802 and the fixed hook 807, the latch module 808 includes a translation latch 810 for controlling The second cylinder 809 moved by the translation pin 810, when the locking mechanism 8 fixes the welding mold 3, taking the welding upper mold 4 as an example, the first cylinder 802 drives the first hinge 804 to pull the fixing hook 807 to fix the upper template 402 Then use the second cylinder 809 to push out the translation pin 810 to hold the fixed hook 807, so as to avoid th...

Embodiment 3

[0046] The technical solution of embodiment 3 is basically the same as the technical solution of embodiment 1, the difference is: a universal ultrasonic welding equipment for glove boxes, which also includes a motion mechanism 7, and the motion mechanism 7 includes a Y-axis motion module 702 and a Z-axis motion module 702 The movement module 701, the movement mechanism 7 drives the welding lower mold 5 to move, when the welding mold 3 is replaced and installed, the locking mechanism 8 fixes the welding lower mold 5, the Y-axis movement module 702 of the equipment moves the welding mold 3 to the position point, and the Z-axis movement module 701 lifts the lower welding die 5 to the fixed pin position of the upper welding die 4. After the upper welding die 4 is fixed, the Z-axis motion module 701 drives the lower welding die 5 to move downward, so that the upper welding die 4 and the lower welding die 5 are separated. open. Here, the Y-axis motion module 702 is set as a servo sc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap