Varnish printing device for UV printer

A printing device and printer technology, applied in printing, non-electric variable control, instruments, etc., can solve the problems that the viscosity cannot reach the design viscosity, the printing nozzle consumes manpower, unfavorable UV varnish leveling and rapid curing, etc., to achieve good printing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

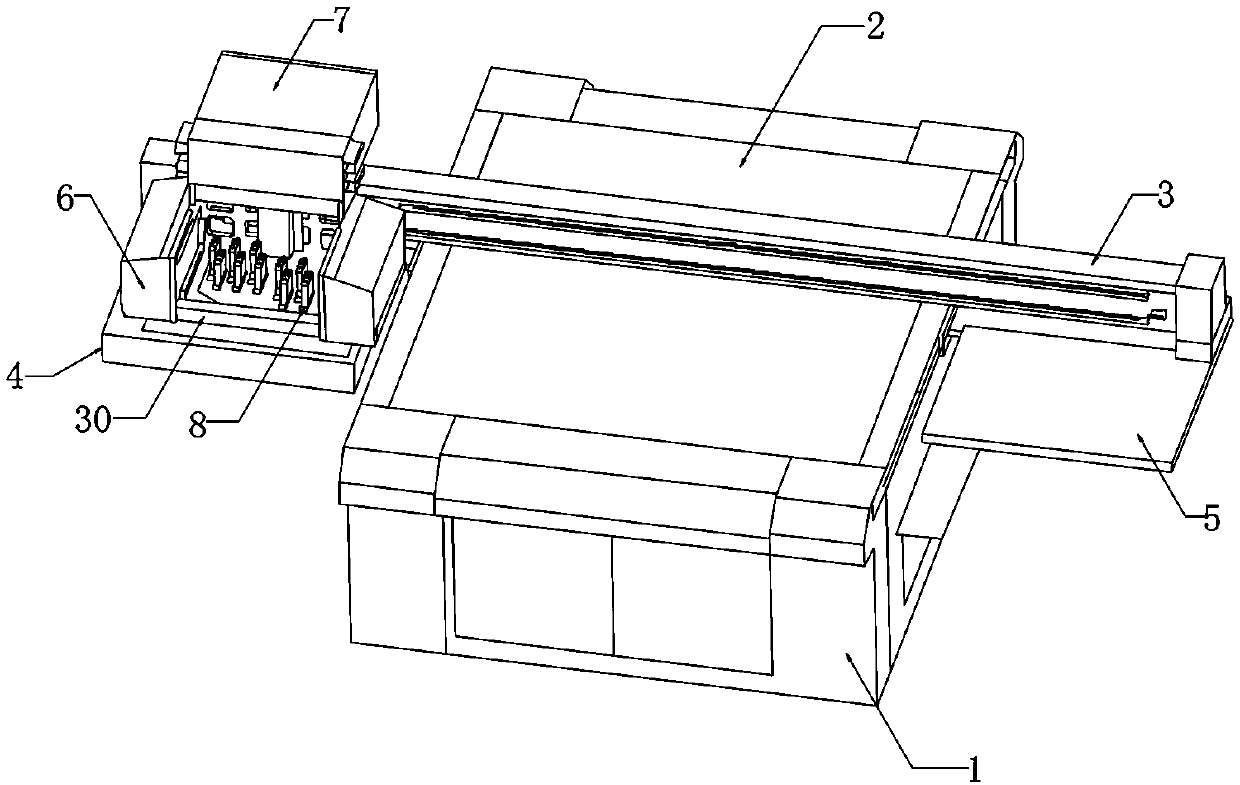

[0027] Such as Figure 1-4 As shown, a varnish printing device for UV printers includes a frame (1), a cleaning table (4) and an installation box (7). A workbench (2) is installed on the top of the frame (1). A cleaning table (4) is installed on one side of the frame (1), a support plate (5) is installed on the other side of the frame (1), and a guide rail (3) is connected to one side of the cleaning table (4), and the guide rail (3 ) is slidingly connected to one side of the mounting box (7).

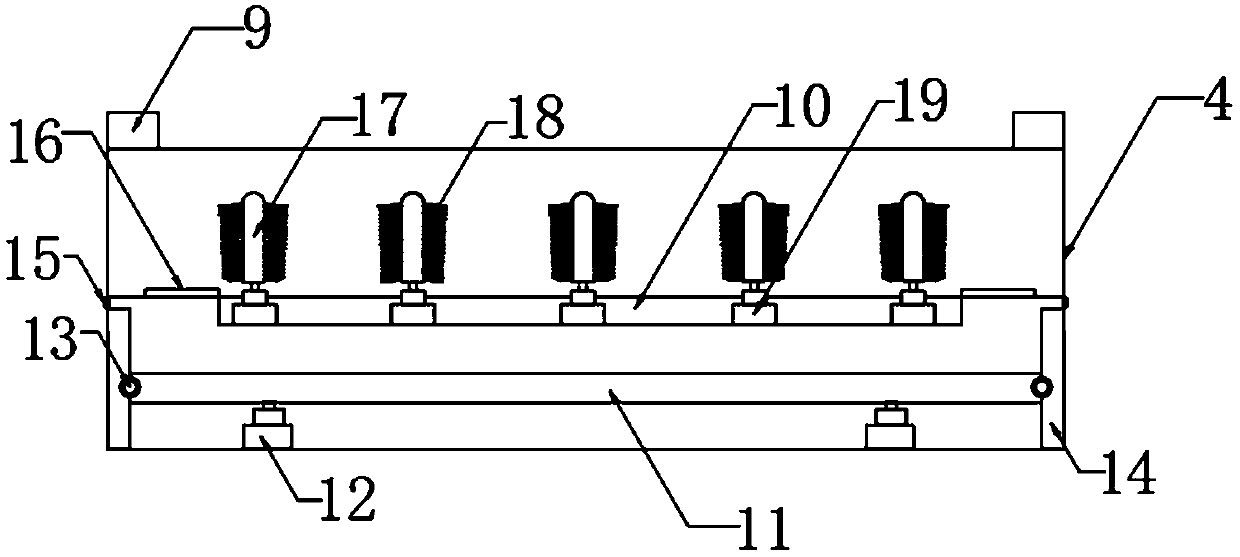

[0028] Limiting blocks (9) are installed on both sides of the top of the cleaning table (4), the middle of the cleaning table (4) is fixed with a mounting plate (10), and filter plates (16) are installed on both sides of the mounting plate (10). The interior of the mounting plate (10) is fixedly installed with several first rotating motors (19), and the rotating shaft of each first rotating motor (19) is fixedly installed with a fixed column (17), and each fixed column (17) The surfa...

Embodiment 2

[0033] Such as Figure 1-4 As shown, a varnish printing device for UV printers includes a frame (1), a cleaning table (4) and an installation box (7). A workbench (2) is installed on the top of the frame (1). A cleaning table (4) is installed on one side of the frame (1), a support plate (5) is installed on the other side of the frame (1), and a guide rail (3) is connected to one side of the cleaning table (4), and the guide rail (3 ) is slidingly connected to one side of the mounting box (7).

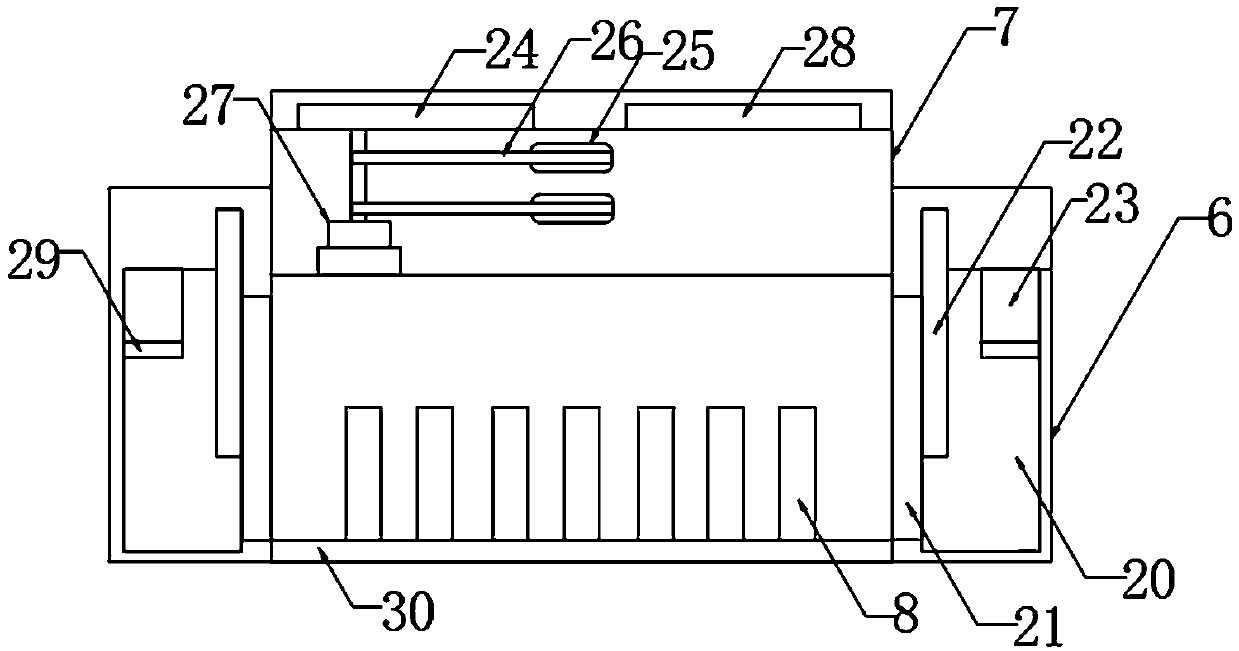

[0034] Both sides of the bottom of the installation box (7) are fixedly installed with a fixed box (6), and one side inside each fixed box (6) is fixedly installed with an air storage box (20), and each inner side of the air storage box (20) Fans (23) are fixedly installed on the top of each fan (23), and heating pipes (29) are fixedly installed at the bottom of each fan (23), and the other side of each air storage box (20) is fixedly equipped with an air guide port (21) , a gate val...

Embodiment 3

[0039] Such as Figure 1-4 As shown, a varnish printing device for UV printers includes a frame (1), a cleaning table (4) and an installation box (7). A workbench (2) is installed on the top of the frame (1). A cleaning table (4) is installed on one side of the frame (1), a support plate (5) is installed on the other side of the frame (1), and a guide rail (3) is connected to one side of the cleaning table (4), and the guide rail (3 ) is slidingly connected to one side of the mounting box (7).

[0040] The two sides of the top of installation box (7) are installed with circuit board (24) and controller (28) respectively, and circuit board (24) is electrically connected with heating tube (29), and controller (28) is respectively connected with guide rail (3 ), varnish printing nozzle (8), push rod motor (12), first rotating motor (19), second rotating motor (27), water valve (15), gate valve (22) and fan (23) Electrically connected, the controller (28) is connected to it thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com