Anti-falling guide rail inspection device for electric power operation and maintenance

A technology for inspection devices and guide rails, applied in mechanical solid deformation measurement, ladders, buildings, etc., can solve problems such as inability to slide, dislocation of anti-fall safety devices, dislocation of guide rails, etc., and achieve the effect of facilitating repair and reducing potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

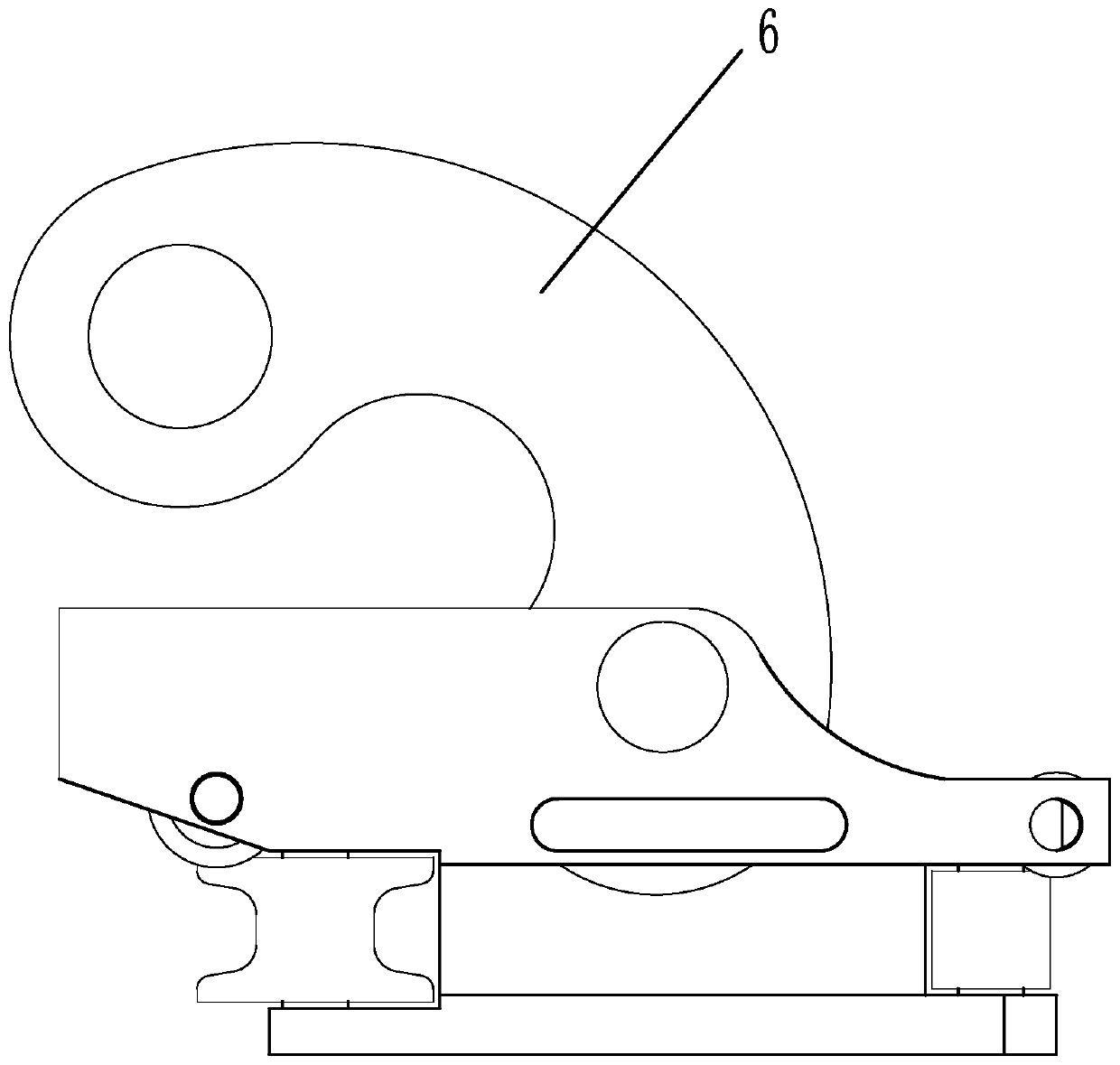

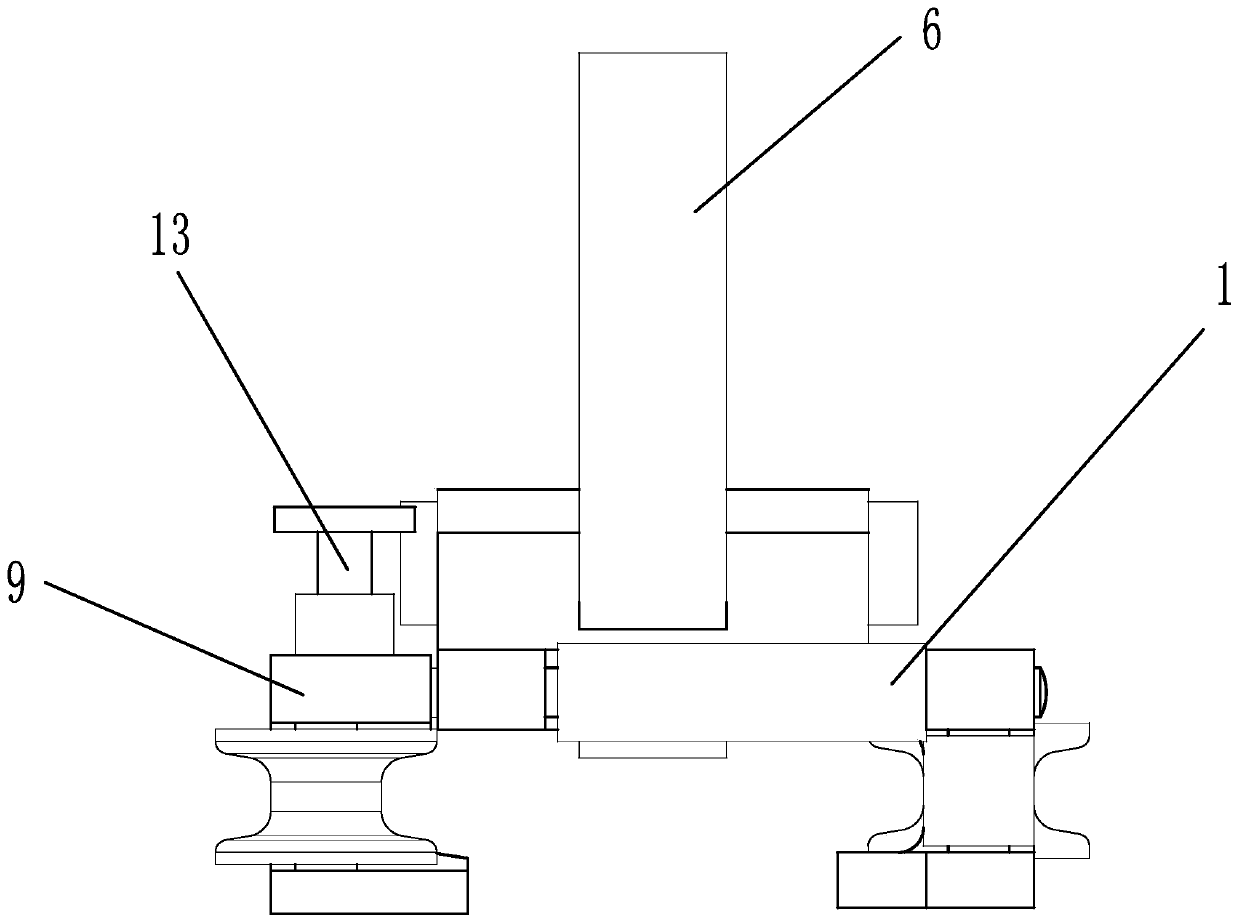

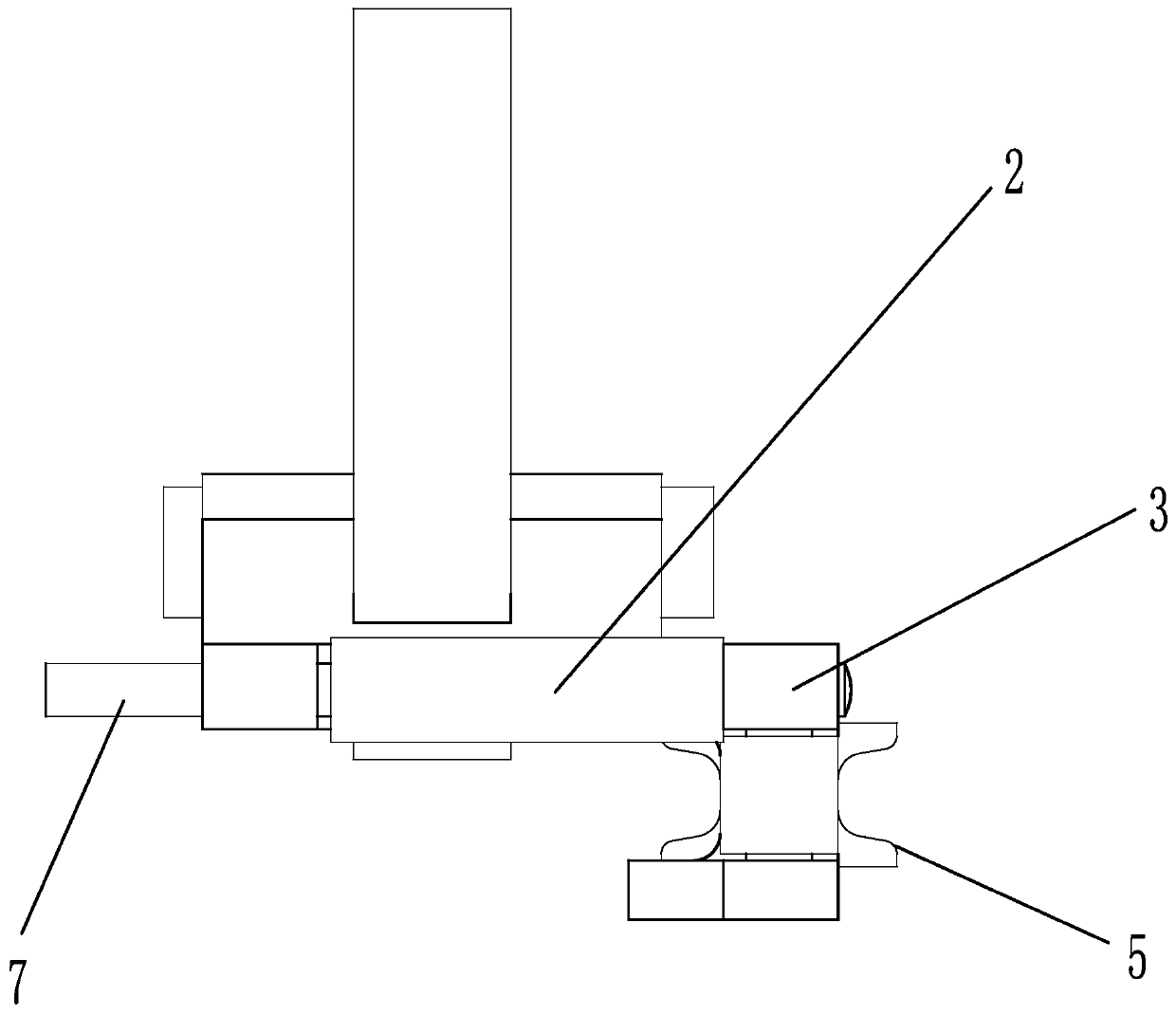

[0021] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, a power operation and maintenance anti-fall guide rail inspection device, including a detection body that slides and cooperates with the guide rail, and the detection body includes a cover that covers the end surface of the guide rail and is slidably connected with one side of the guide rail. The first main body 1 and the second main body 9 slidingly connected with the other side of the guide rail, the first main body and the second main body are detachably connected, and the cam 6 is hinged on the first main body. An adjustable limiter for preventing the separation and loss of the first body and the second body is passed between the first body and the second body, and the adjustable limiter is a limiter passed between the first body and the second body Bit screw or wire rope. The first main body includes a mounting plate 2 parallel to the end face of the guide rail and a side plate 3 positioned on one side of the mounting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com